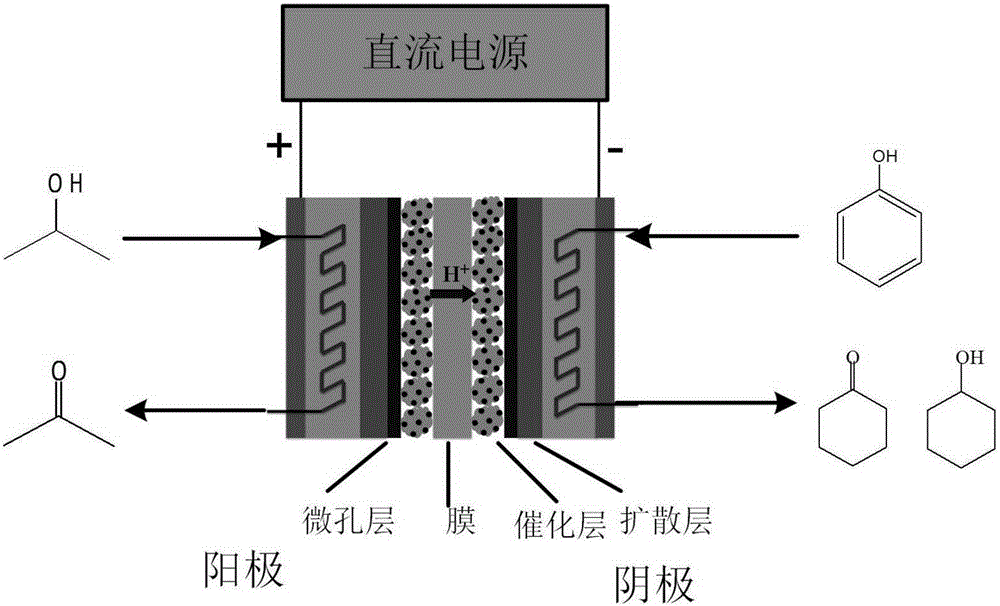

Electrochemistry hydrogen pump dual reactor for organic matter dehydrogenation and hydrogenation coupling

An electrochemical and reactor technology, applied in the field of electrochemical engineering, can solve the problems of high temperature for reaction and difficult separation of products, and achieve the effect of simplifying the reaction process, simplifying the separation process, and saving equipment and transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

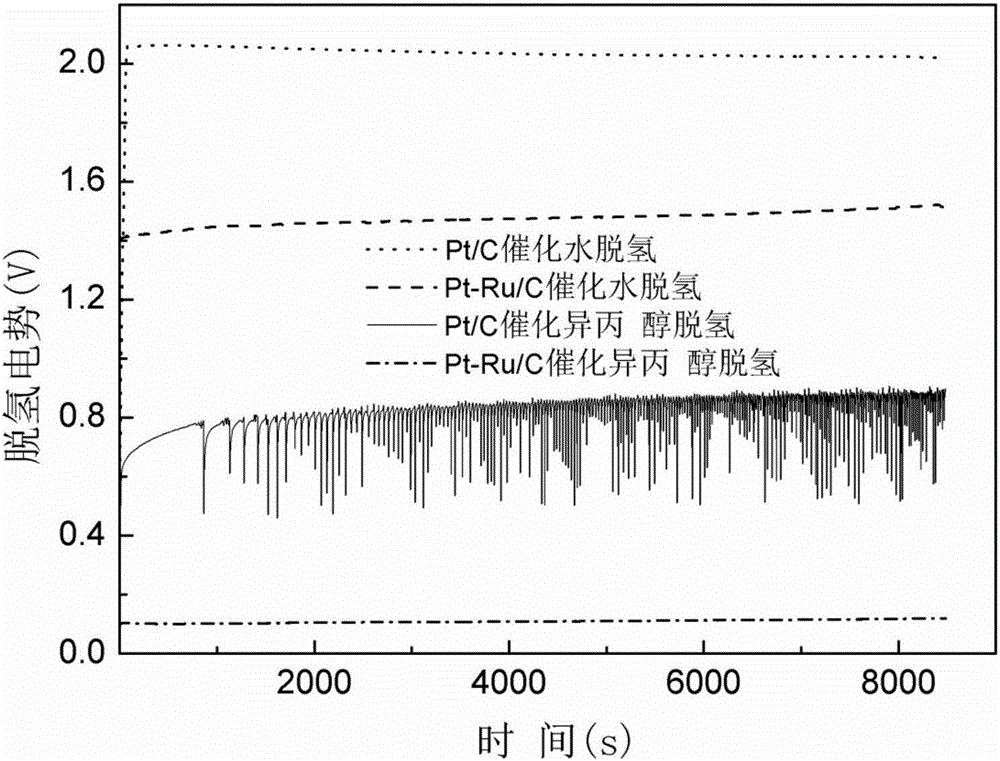

Embodiment 1

[0022] The loading capacity of the anode is 4.0mgcm -2 PtRu gas diffusion electrode, the loading capacity of the cathode is 0.5mgcm -2 Pt gas diffusion electrode. The treated Nafion117 membrane and cathode and anode gas diffusion electrodes were placed in an oil press, and a gas diffusion three-in-one membrane electrode was made by hot pressing at 140°C and 5MPa for 90s. Put the assembled gas-diffusion three-in-one membrane electrode in the electrochemical hydrogen pump reactor, and raise the temperature of the reactor to 80°C. Pass 1mol / L isopropanol aqueous solution into the anode at a flow rate of 10mL / min; pass 0.1mol / L phenol aqueous solution into the cathode at a flow rate of 10ml / min, and run at a constant current of 100mA for 3h. The anode voltage is controlled at 0.2V, and the anode dehydrogenation rate is 61.6mmolcm -1 the s -1 , and the current efficiency is 62.8%. Take the cathode hydrogenation product and add the internal standard to carry out the gas chromat...

Embodiment 2

[0024] The loading capacity of the anode is 0.5mgcm -2 Pt gas diffusion electrode, the loading capacity of the cathode is 0.5mgcm -2 Pt gas diffusion electrode. The treated Nafion117 membrane and cathode and anode gas diffusion electrodes were placed in an oil press, and a gas diffusion three-in-one membrane electrode was made by hot pressing at 140°C and 3MPa for 60s. Place the assembled gas-diffusion three-in-one membrane electrode in the electrochemical hydrogen pump reactor, and raise the temperature of the reactor to 60°C. Pass 2mol / L isopropanol aqueous solution into the anode at a flow rate of 10ml / min; pass 0.1mol / L phenol aqueous solution into the cathode at a flow rate of 10mL / min, run at a constant current of 100mA for 1 hour, and control the anode voltage at 0.8V , the anode dehydrogenation rate is 60.7mmolcm -1 the s -1 , the current efficiency is 62.0%, and the cathode hydrogenation product is added to the internal standard substance for gas chromatography te...

Embodiment 3

[0026] The loading capacity of the anode is 4.0mgcm -2 PtRu gas diffusion electrode, the loading capacity of the cathode is 0.5mgcm -2 Pd gas diffusion electrode. The treated Nafion117 membrane and cathode and anode gas diffusion electrodes were placed in an oil press, and a gas diffusion three-in-one membrane electrode was made by hot pressing at 140°C and 5MPa for 90s. Put the assembled gas-diffusion three-in-one membrane electrode in the electrochemical hydrogen pump reactor, and raise the temperature of the reactor to 80°C. Pass 1mol / L isopropanol aqueous solution into the anode at a flow rate of 10mL / min; pass 0.1mol / L phenol aqueous solution into the cathode at a flow rate of 10mL / min, and run at a constant current of 100mA for 1h. The anode voltage is 0.6V, and the anode dehydrogenation rate is 61.6mmolcm -1 the s -1 , and the current efficiency is 62.8%. The cathode hydrogenation product was added with an internal standard for gas chromatographic testing, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com