Electric dual-girder-bridge type stacking device and stacking method thereof

An electric and stacking technology, applied in the directions of transportation and packaging, loading/unloading, conveyor objects, etc., can solve the problems of increasing difficulty in the design and construction of the roof of the yard and increasing investment, so as to reduce engineering construction investment and reduce the occupation. land area and the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with embodiments.

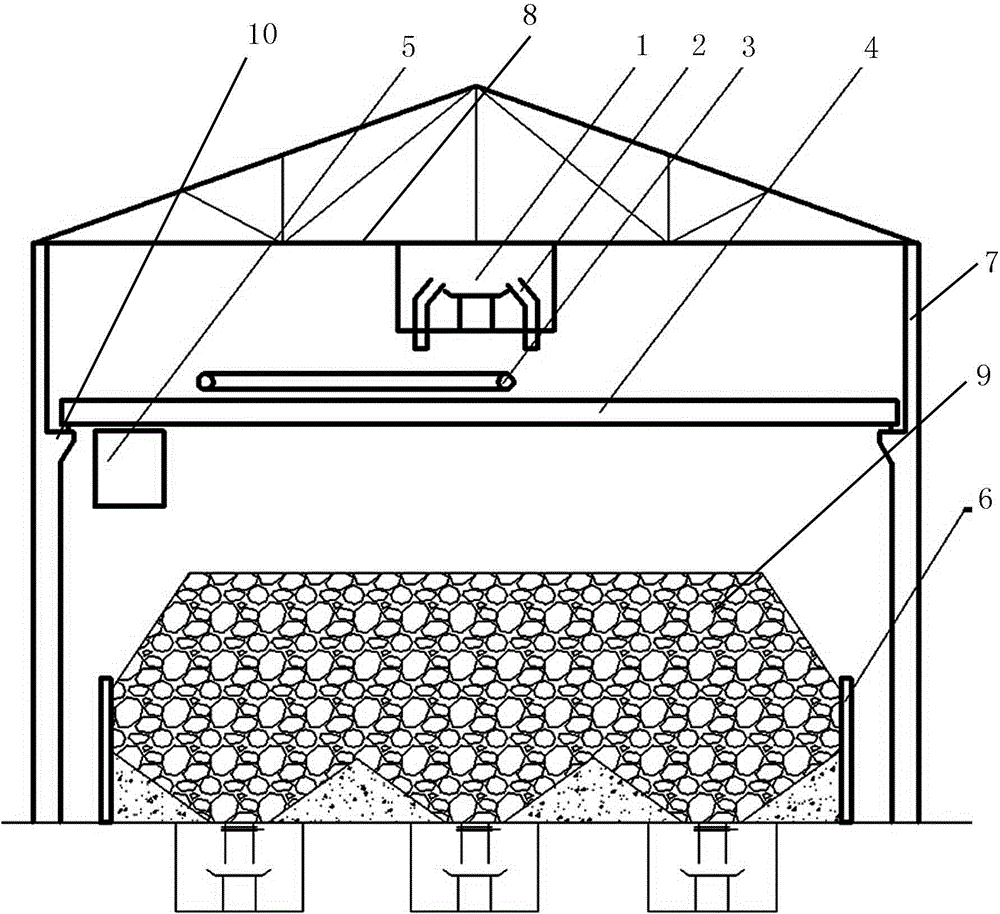

[0018] As shown in the figure, an electric double-girder bridge-type stacking device of the present invention includes a portal steel frame 7, and a feeding belt conveyor 1 and an unloading trolley 2 are arranged below the girder 8 of the portal steel frame 7. There is an electric double-girder bridge-type working platform 4 under the material trolley 2, a reversible belt conveyor 3 is set above the electric double-girder bridge-type working platform 4, and an operating room is set under the electric double-girder bridge-type working platform 4. 5.

[0019] The reversible warehouse distribution belt conveyor 3 moves left and right along the track on the electric double-beam bridge-type working platform 4 .

[0020] The electric double-girder bridge-type working platform 4 and the unloading trolley 2 move synchronously along the length direction of the portal steel frame 7 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com