Rack and pinion steering gear sealing structure

A technology of sealing structure and rack and pinion, which is applied in the direction of mechanical steering gear, engine sealing, engine components, etc., can solve problems such as seal prolapse, increase interference and resistance, reduce human resource investment, and reduce product quality. The effect of quality risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

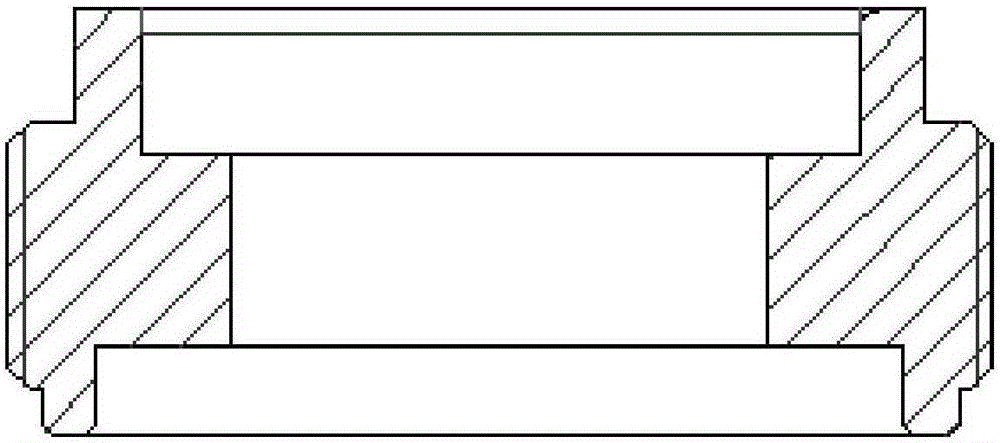

[0016] figure 1 It is a structural schematic diagram of a gear shaft adjusting screw plug in the prior art. The structural design of the high and low pressure oil seals or dust seals used in the prior art is relatively simple, especially after the high and low pressure oil seals and dust seals receive the hydraulic impact force and the axial and radial forces are durable, the high and low pressure oil seals and the anti The dust seal has the phenomenon and risk of coming out, which will lead to oil leakage from the hydraulic sealing part of the steering gear or water leakage from the dust-proof part of the steering gear seal, which will lead to the failure of the steering hydraulic power booster and the internal corrosion of the steering gear, resulting in steering sticking and abnormal noise.

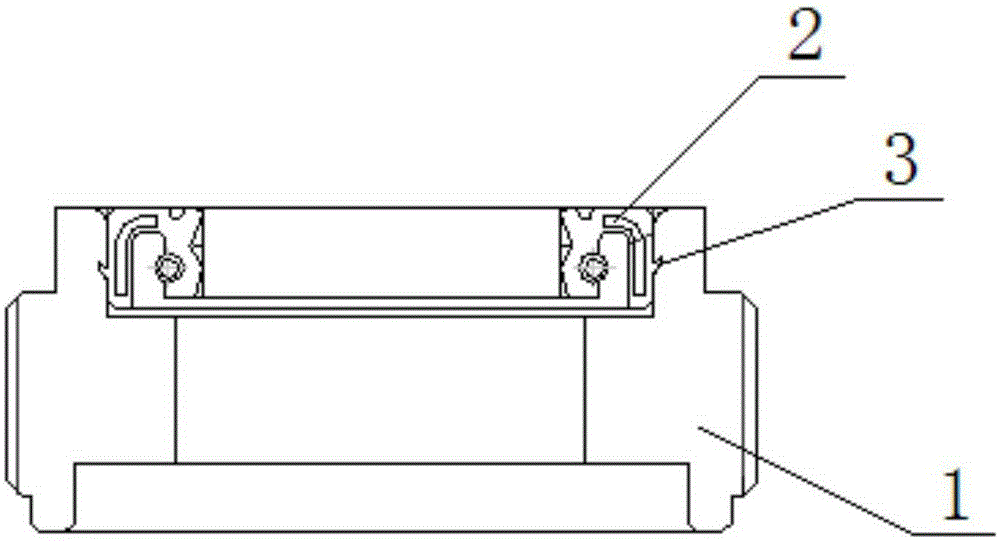

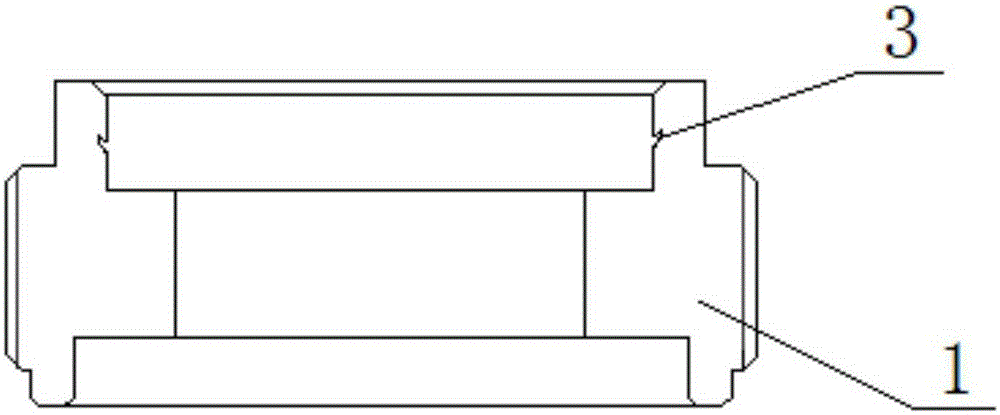

[0017] figure 2 It is a structural schematic diagram of the sealing structure of the rack and pinion steering gear of the present invention, image 3 Schematic diagram of the struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com