Method for treating volatile matter in cleaning process of open type oil storage tank

A treatment method and technology for volatile substances, which are applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of large investment in oil storage tank cleaning, inability to achieve no odor diffusion, etc., and improve operating conditions and costs. Low, odor control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

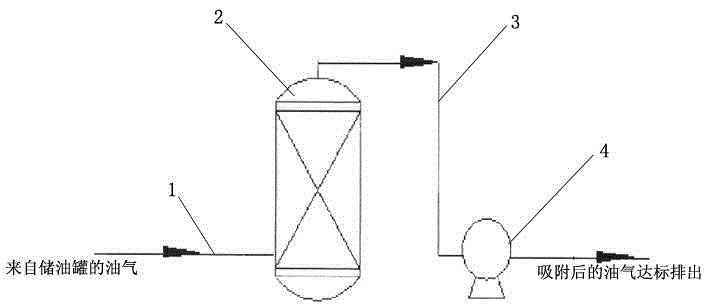

[0027] Take the solvent oil stored in the floating roof tank as an example. When cleaning the floating roof tank, first turn on the fan to pump the oil and gas in the oil storage tank from the manhole and enter the bottom of the adsorption tank along the first pipeline; the oil and gas entering the adsorption tank pass through the adsorption tank. The activated carbon layer in the tank, after being adsorbed by activated carbon, enters the fan from the top of the adsorption tank along the second pipeline, and the oil and gas from the fan are discharged up to the standard (GB20950-2007 Emission Standard of Air Pollutants for Oil Storage). The wind speed at the other manhole of the oil storage tank is 0.1m / s, and the air speed of the adsorption tank is 20h -1 .

Embodiment 2

[0029] Taking the storage of kerosene in the vault tank as an example, when cleaning the vault tank, first turn on the fan, pump the oil and gas in the oil storage tank from the manhole and enter the bottom of the adsorption tank along the first pipeline; the oil and gas entering the adsorption tank pass through the adsorption tank The molecular sieve layer inside, after being adsorbed by the molecular sieve, enters the fan from the top of the adsorption tank along the second pipeline, and the oil and gas from the fan are discharged up to the standard (GB20950-2007 Emission Standard of Air Pollutants for Oil Storage). The wind speed at the other manhole of the oil storage tank is 3m / s, and the air speed of the adsorption tank is 500h -1 .

Embodiment 3

[0031] Taking the storage of diesel oil in the vault tank as an example, when cleaning the vault tank, first turn on the fan to pump the oil and gas in the oil storage tank from the manhole and enter the bottom of the adsorption tank along the first pipeline; the oil and gas entering the adsorption tank pass through the adsorption tank The molecular sieve layer inside, after being adsorbed by the molecular sieve, enters the fan from the top of the adsorption tank along the second pipeline, and the oil and gas from the fan are discharged up to the standard (GB20950-2007 Emission Standard of Air Pollutants for Oil Storage). The wind speed at the other manhole of the oil storage tank is 5m / s, and the air speed of the adsorption tank is 1000h -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com