Detachable explosion venting door

An explosion venting door and pressure relief door technology, applied in the field of explosion venting doors, can solve the problems of hidden safety hazards of scaffolding, long power outage, troublesome disassembly and installation, etc., and achieve the effects of avoiding secondary damage, saving construction period and protecting safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

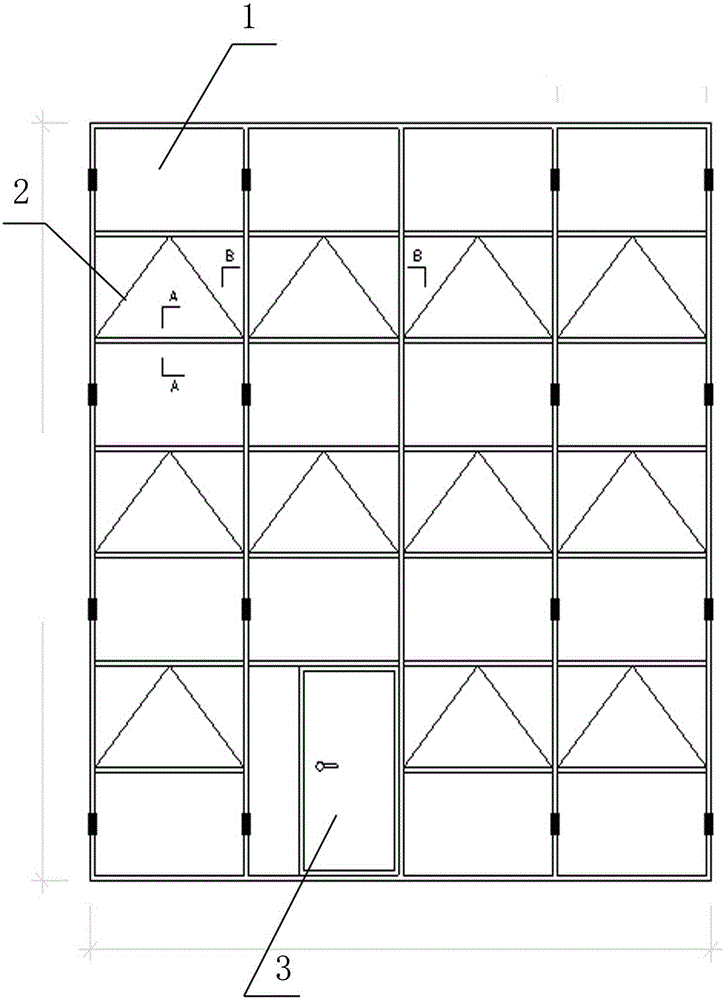

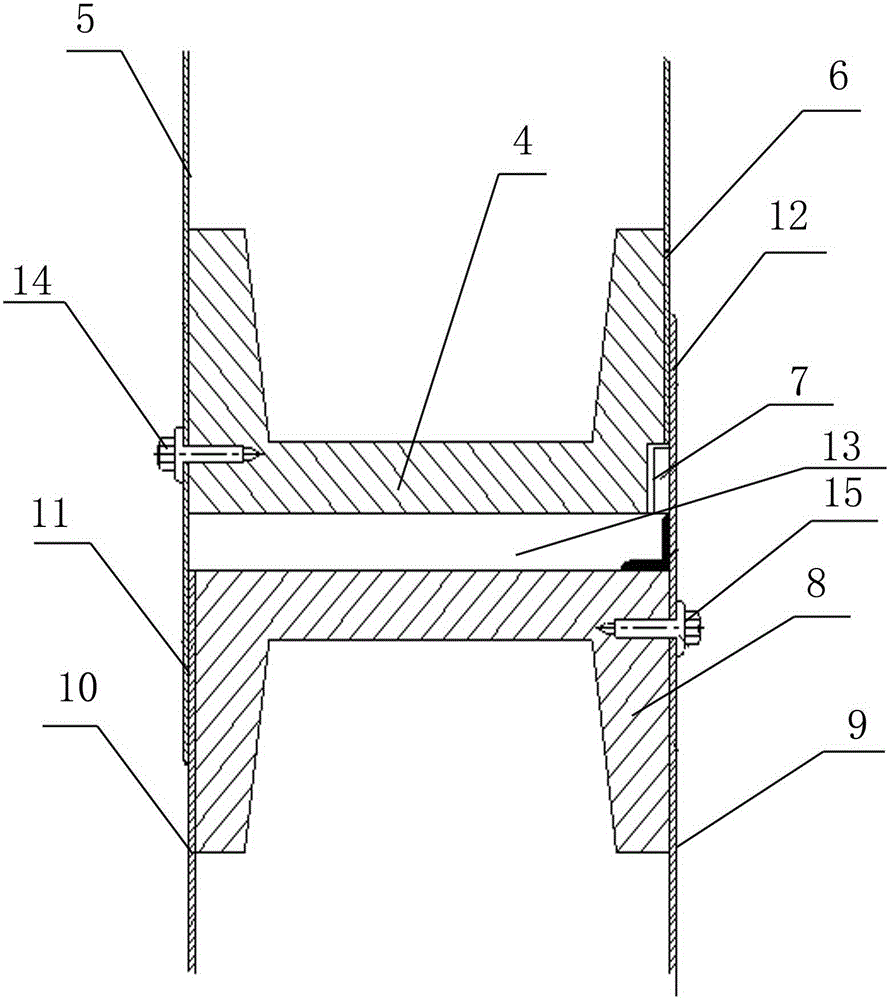

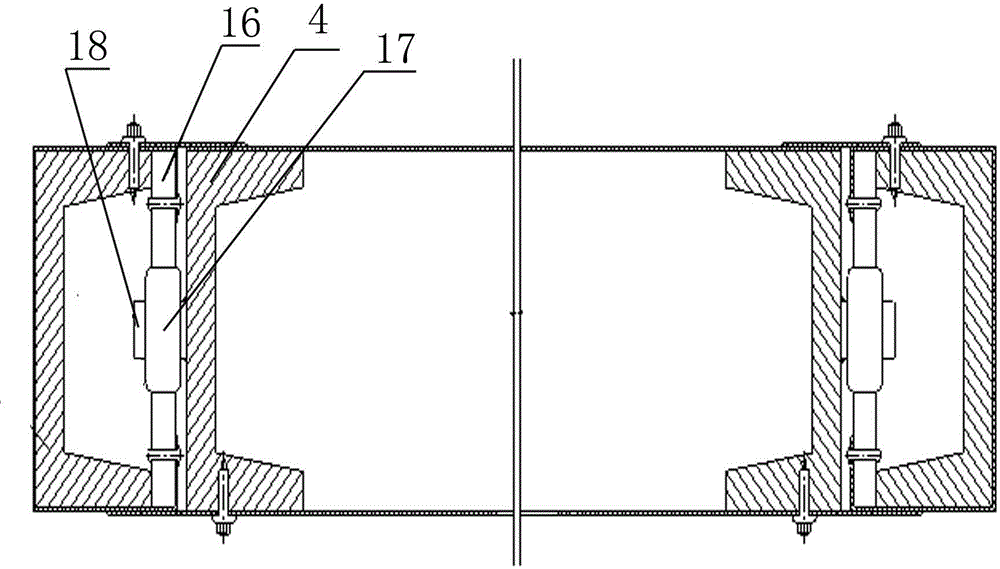

[0010] exist figure 1 , figure 2 and image 3 Among them, the present invention provides a detachable explosion venting door, which includes several layers of pressure relief walls 1 and several layers of pressure relief devices 2, and several layers of pressure relief walls 1 and several layers of pressure relief devices 2 are arranged at intervals up and down A pressure relief door body is formed. The pressure relief door of this embodiment includes a four-layer pressure relief wall 1 and a four-layer pressure relief device 2. An access door 3 is provided at the bottom of the pressure relief door body. The pressure relief of each layer The device 2 is assembled from a number of movable pressure relief plate assemblies. Each layer of pressure relief device 2 in this embodiment is assembled from four movable pressure relief plate assemblies. Each of the movable pressure relief plate assemblies includes a movable plate skeleton 4. The outer side of the plate frame 4 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com