Valve body optimization design method

An optimized design and valve body technology, applied in calculation, special data processing applications, instruments, etc., can solve the problem that the valve design method cannot give full play to the material performance, and achieve the effects of shortening the design modification time, ensuring safety, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

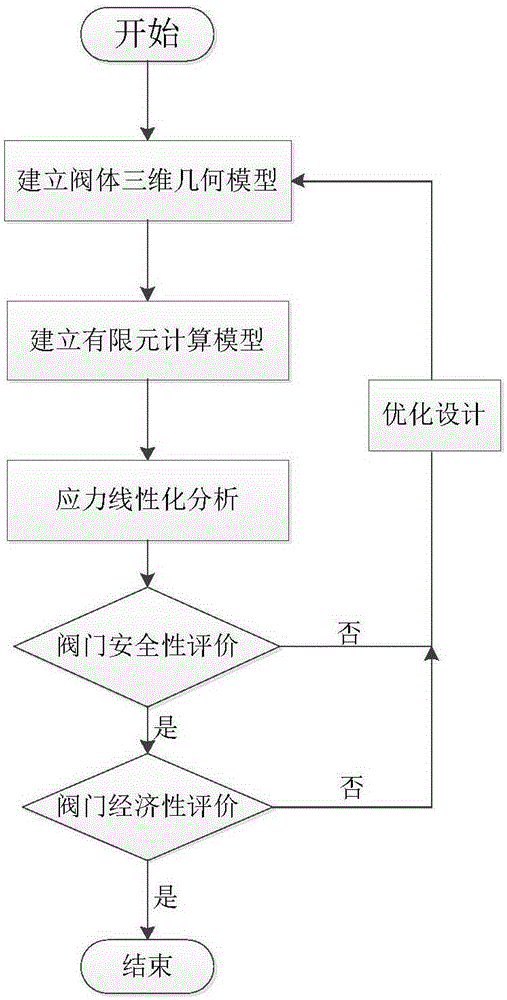

[0045] This embodiment provides a valve body optimization design method, the valve body is a DN650 gate valve, including the following steps, the process is as follows figure 1 Shown:

[0046] S1: Establish a three-dimensional geometric model of the valve body;

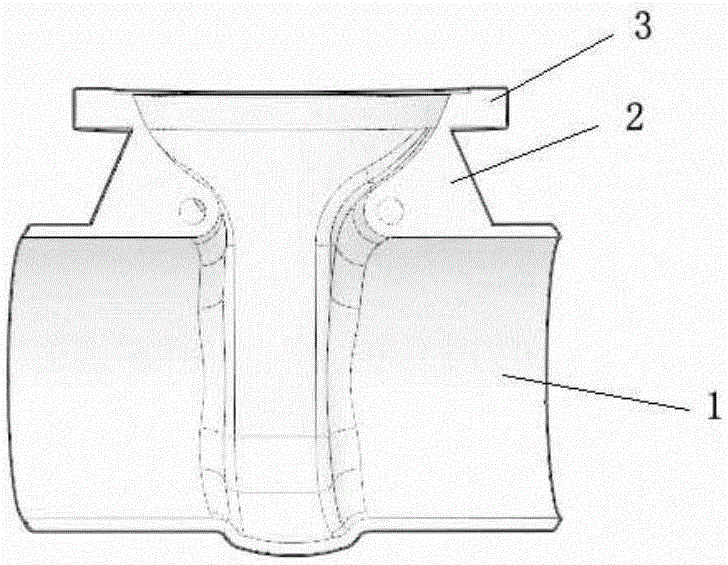

[0047]The design pressure of the valve is 5.1MPa, the preliminary design of the valve body. The thickness of the preliminarily designed valve cavity wall area 1 is 32.8mm, the thickness of the rib area 2 is 45mm, the thickness of the middle flange area 3 is 95mm, there is a φ60 hole on the rib plate, and the material allowable stress of the valve body It is 138MPa. According to the two-dimensional design drawing of the valve body, the three-dimensional geometric model of the valve body is established by using the parameter method in the three-dimensional geometric modeling software. Due to the symmetry of geometry and loads, it is sufficient to establish a 1 / 2 model.

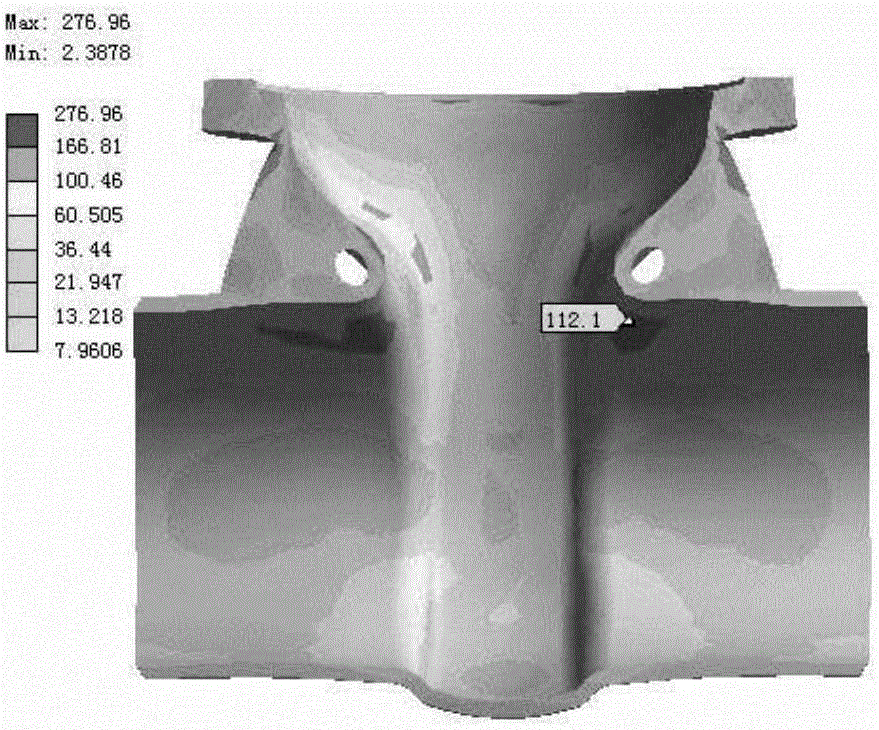

[0048] S2: Use finite element software to est...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com