Hob Composite Abrasion Tester

A technology of experimental instrument and hob, which is applied in the direction of testing wear resistance, etc., can solve the problems that cannot be directly predicted, and can not effectively carry out research on the primary wear and secondary wear of the tool, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described:

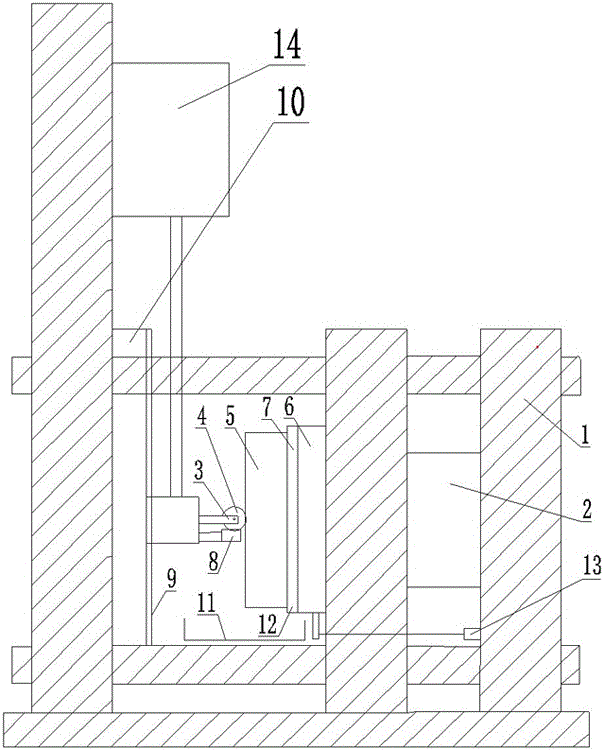

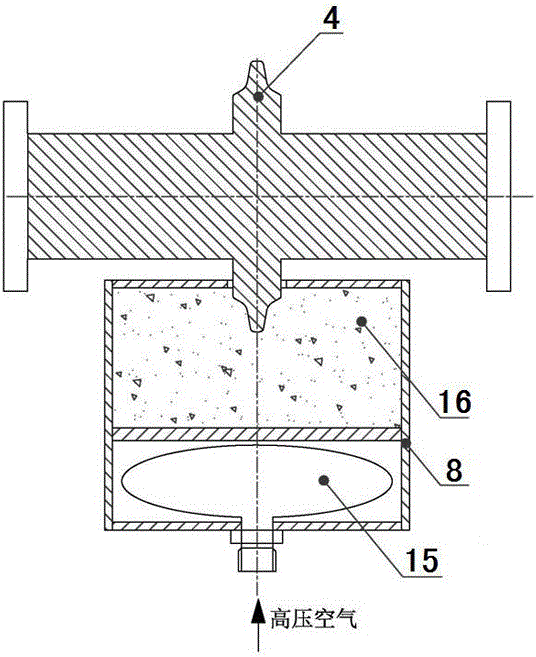

[0022] Such as figure 1 As shown, the hob composite abrasion tester includes a loading frame 1, and a horizontal measurement and control loading measurement and control subsystem, a vertical loading measurement and control subsystem, a rock sample and model hob abrasion mechanism, and a model hob measurement system installed in the loading frame 1. Mechanism and subsystem integration and realization of automatic control system;

[0023] The horizontal measurement and control loading measurement and control subsystem includes a servo pressure cylinder 2 and a horizontal guide rail 9 arranged at the bottom of the loading frame 1; the servo pressure cylinder 2 is connected to a hydraulic pump station, and its end is connected to a rock sample and a model hob for abrasion The rock sample clamp 6 in the action mechanism; the load sensor 12 and the horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com