Automatic testing equipment for testing the airtight performance of rim welds

An automatic detection and performance technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and by detecting the appearance of fluid at the leakage point, can solve the problems of poor reliability, high cost, and low efficiency, and achieve true performance indicators Reliable, extended service life, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0030] The present invention will be described in detail below with reference to the accompanying drawings and examples.

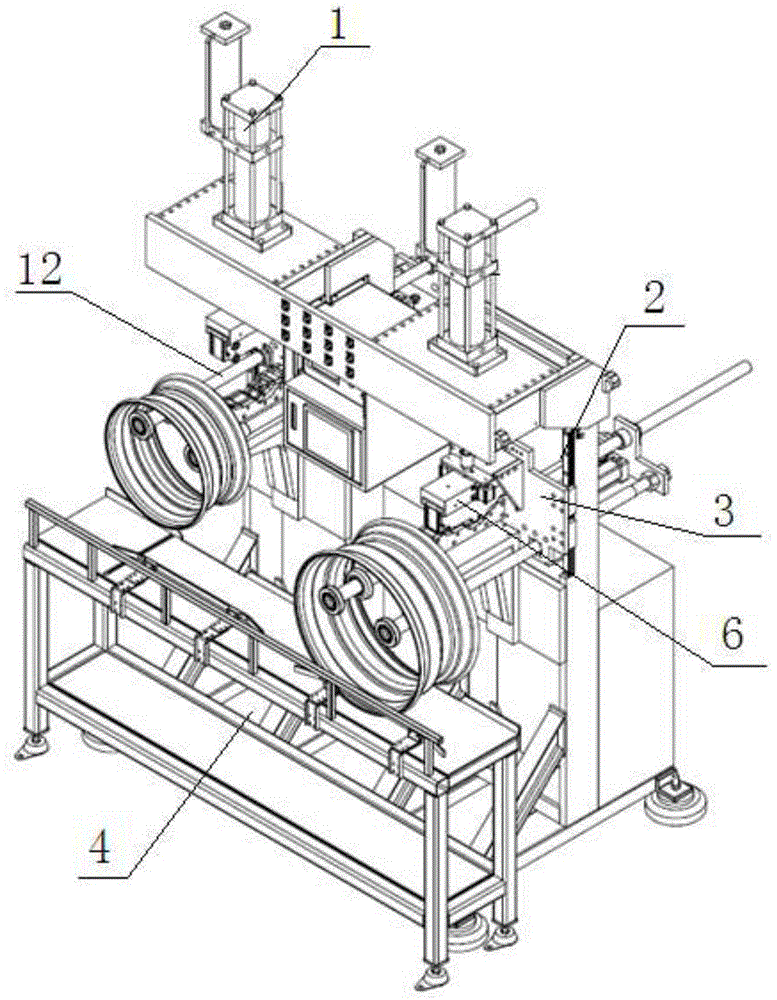

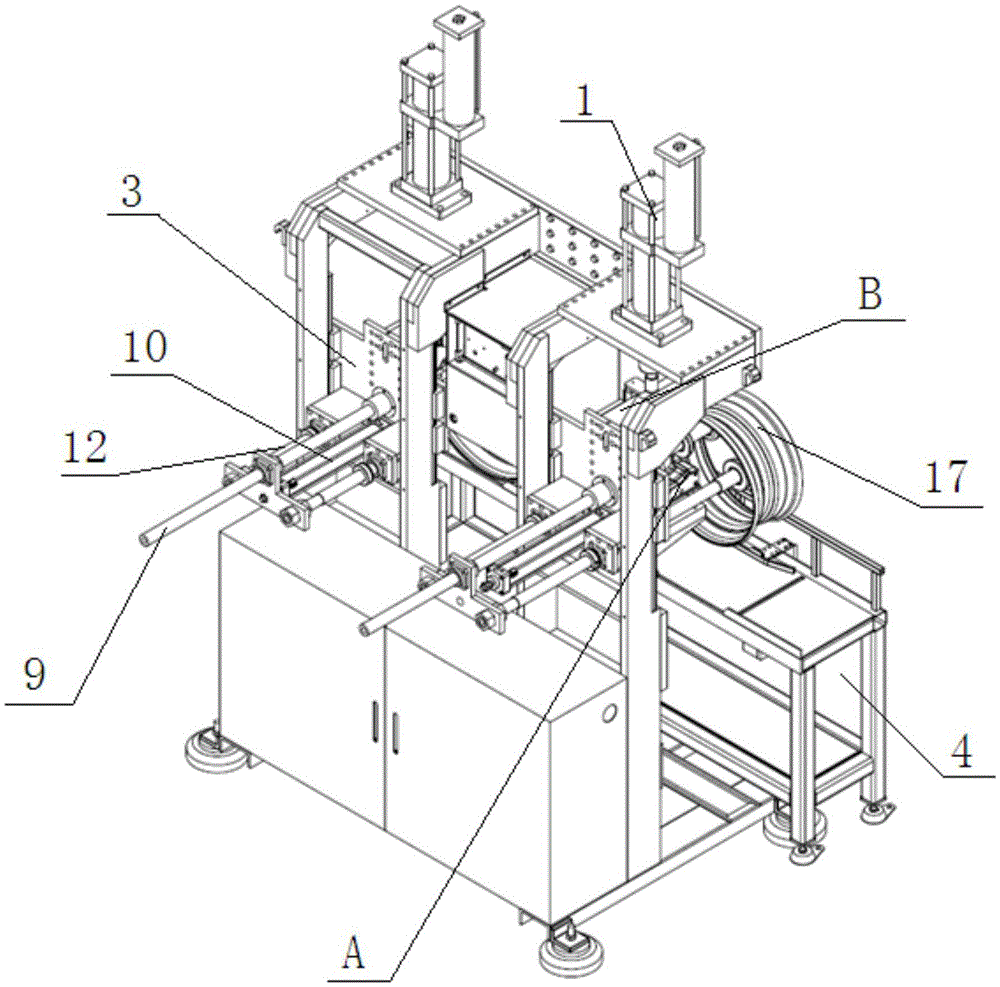

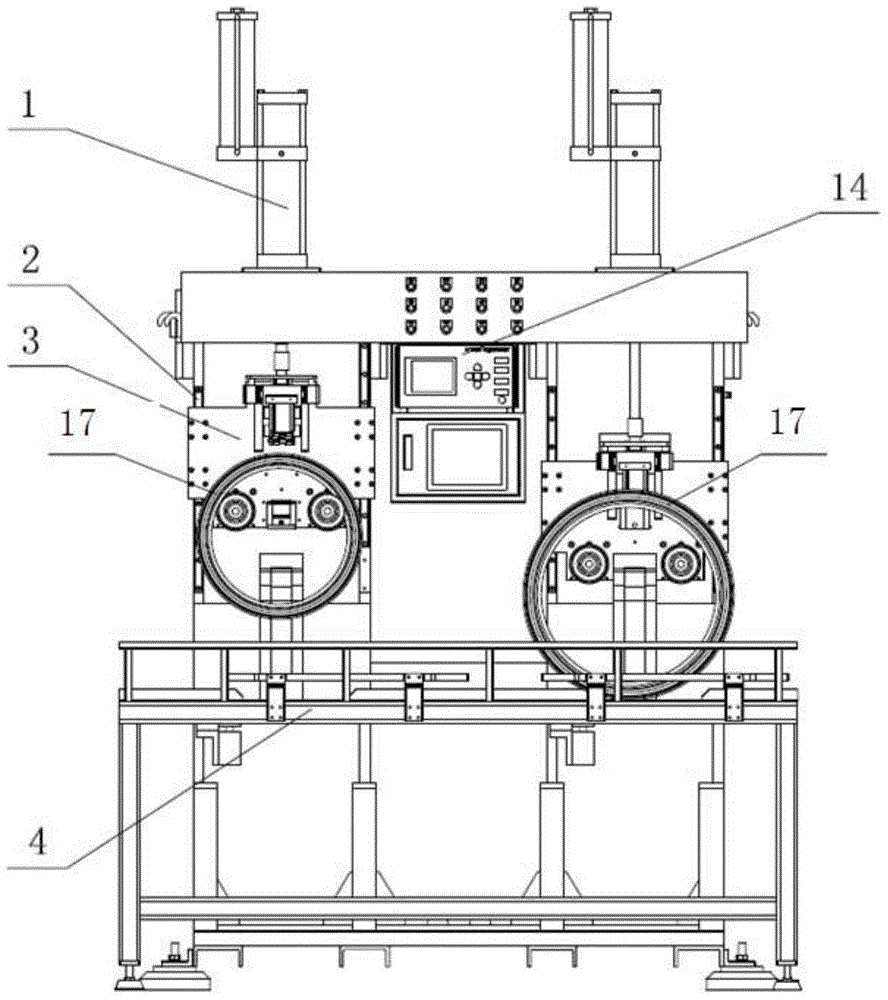

[0031] For the automatic detection equipment provided by the present invention for testing the airtight performance of the rim weld, refer to figure 1 As shown, before feeding, the wheel rim 17 is fed through the conveying line body 4, and the wheel rim 17 rolls on its own along a slightly gentle slope, and stops after setting a block at the corresponding station.

[0032] Considering the diversity of the sizes of the rims 17 of different wheels, the maximum stroke of the gas-hydraulic pressurized cylinder 1 is 200mm, the height of the conveying line body 4 at the production site is 820mm, and the dimensions of the largest and smallest rims, and the bottom surface distance of the tooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com