An online weighing device for tobacco leaves

A weighing device and tobacco leaf technology, which is applied to measuring devices, automatic feeding/discharging weighing equipment, and weighing, etc., can solve the problems of inapplicability to online grading of tobacco leaves, inaccurate weight, and low efficiency. , to achieve the effect of saving time, improving weight accuracy, and reliable theoretical basis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

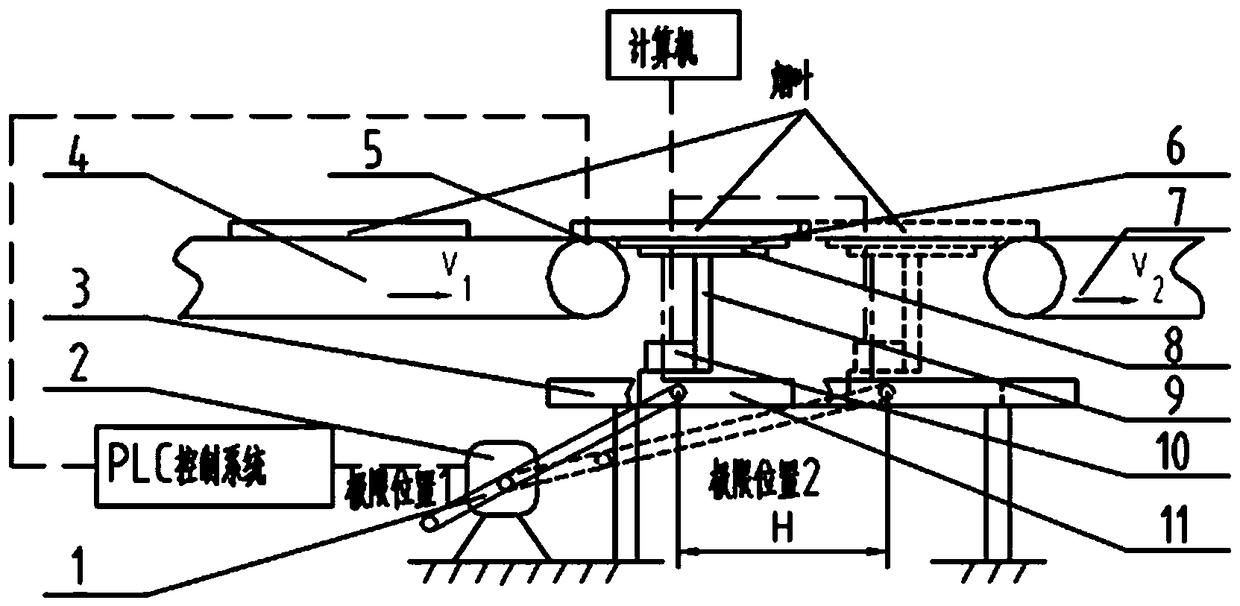

[0013] figure 1 As shown, the specific implementation is as follows:

[0014] An online weighing device for tobacco leaves, comprising a belt conveyor I4, a belt conveyor II7, a transfer weighing device, a PLC control system and a computer, and the transfer weighing device is arranged at the end of the belt conveyor I4 and the belt conveyor II7 Between the starting ends, the transfer weighing device includes a weighing pan 6, a weighing pan support frame 8, a pole 9, a strain gauge load cell 10 and a base 11, and the weighing pan 6 is installed on the weighing pan support frame 8, The weighing pan support frame 8 is installed on the base 11 through the pole 9, and the strain gauge load cell 10 is installed on the pole 9 for detecting the weight of the tobacco leaves on the weighing pan 6 and transmitting the detected data to the computer through the data line , the base 11 is slidably set on the workbench through the bracket guide rail 3, the base 11 is connected to the servo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com