Transformer winding deformation quantitative diagnosis method based on model correction

A technology for transformer winding and model correction, which is applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement device, etc., can solve problems such as quantitative diagnosis, and achieve the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

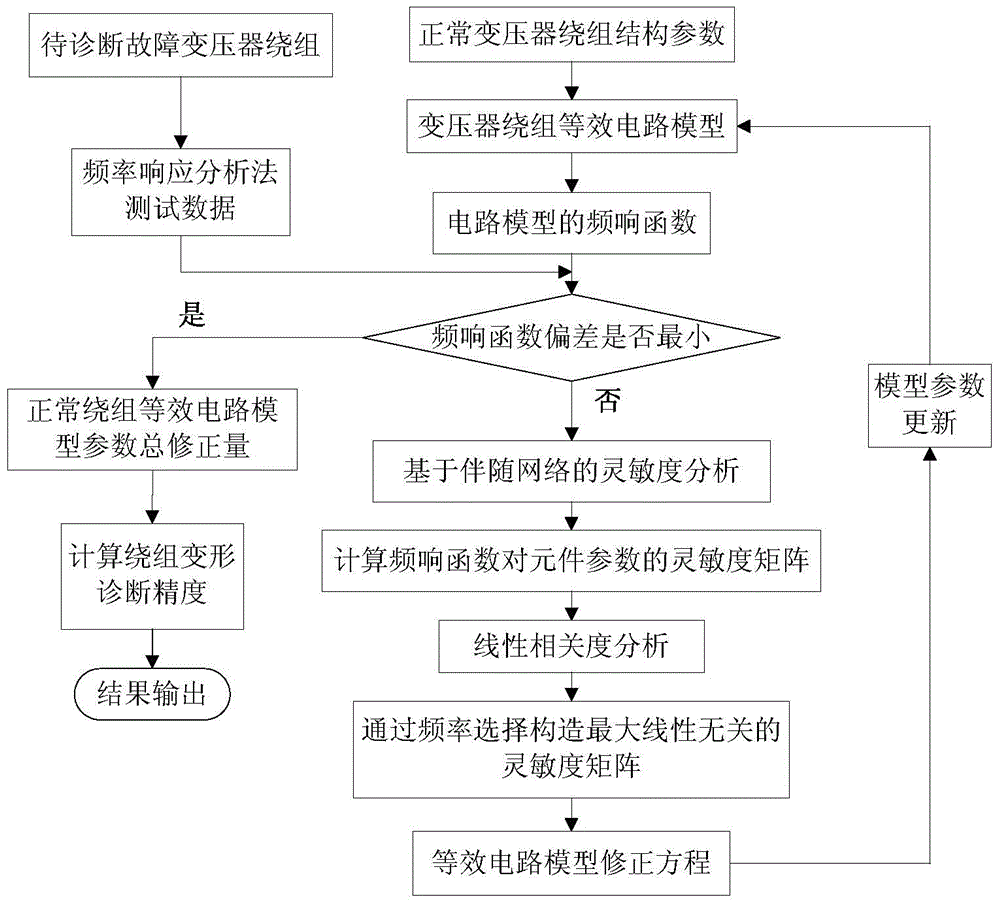

[0063] The present invention proposes a method for quantitative diagnosis of transformer winding deformation based on model correction, the flow chart is as follows figure 1 shown, including the following steps:

[0064] Step1. Detect the frequency response characteristic data of the faulty transformer winding to be diagnosed by the frequency response analysis method;

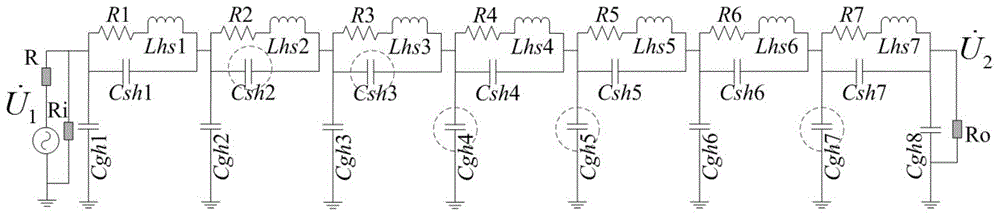

[0065] Step2. Establish the equivalent circuit model of the winding according to the structural parameters of the normal winding transformer:

[0066]

[0067] In the formula, L, R and C are parameter matrices related to the energy storage inductance, energy dissipation resistance or conductance and energy storage capacitance respectively; the charge vector q is taken as the output response vector of the circuit model; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com