Measuring device and method for measuring outer diameter and roundness of large-diameter gas cylinders

A measuring device and large-diameter technology, applied in the field of measurement, can solve the problems of difficult rotation, frequent hoisting, and difficult realization of large-size circular pipes, and achieve measurement accuracy and economic applicability, reduce human interference, and reduce detection costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in conjunction with accompanying drawing and specific embodiment:

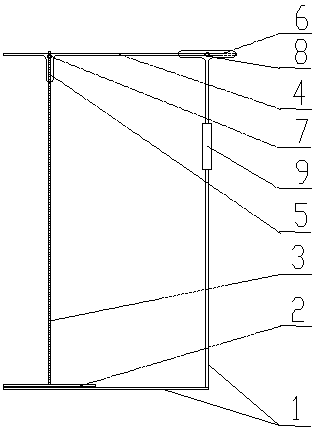

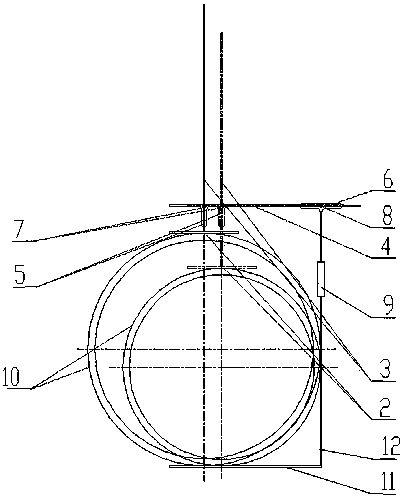

[0019] Such as figure 1 As shown, a measuring device for the outer diameter and roundness of a large-diameter gas cylinder, the measuring device has a rigid right-angle frame 1 for placing the gas cylinder to be tested; the rigid right-angle frame 1 is composed of a vertical rod 12 and a The cross bar 11 at the lower end of the vertical bar is formed; the upper end of the vertical bar 12 is fixedly connected with a chute I6 for the sliding of the cantilever cross bar 4; the described chute I6 is arranged horizontally; and set parallel to the crossbar 11; the cantilever crossbar 4 can slide horizontally along the chute I6 and fastened by the fastening screw I8; the measuring device also includes a scale 3; the scale 3 is arranged parallel to the vertical rod 12; the scale of the scale 3 increases sequentially from top to bottom; the upper end of the scale 3 slides with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com