Antifreeze control method and system for heat pump unit

A heat pump unit and control method technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of low outlet water temperature, evaporator freezing, and low evaporation pressure of the unit system, so as to prevent the temperature from being too low and increase the The effect of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

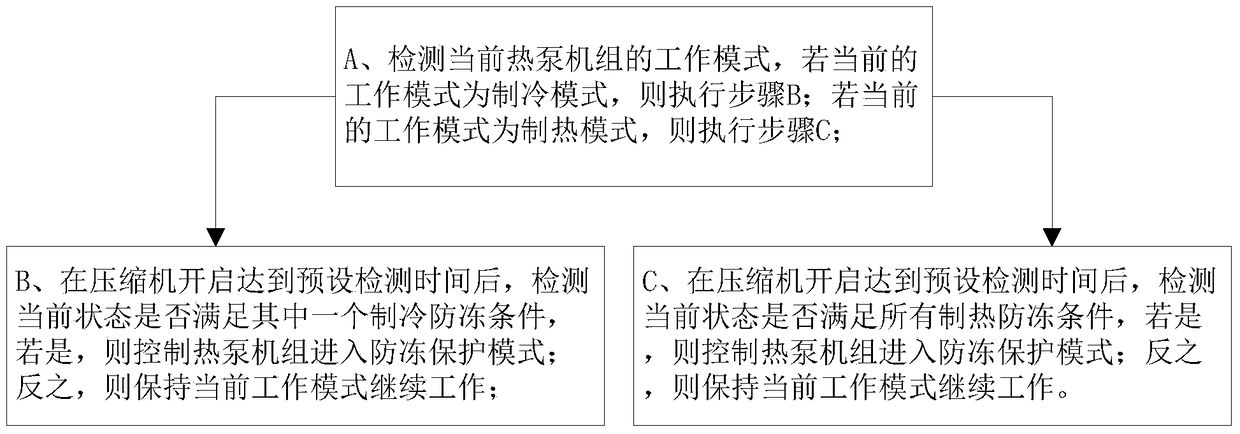

[0062] In a specific embodiment of the present invention, the preset detection time is 30s, the antifreeze pressure threshold is 5bar, and the preset pressure detection time is 10s.

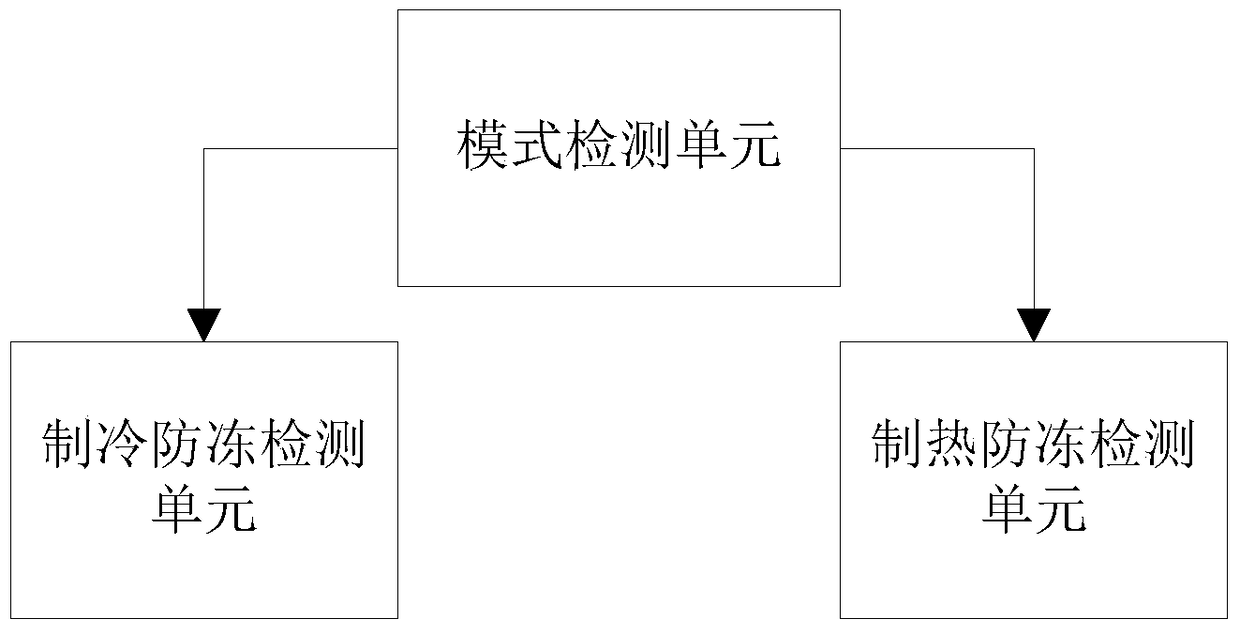

[0063] When in the cooling mode, after the compressor is turned on for 30 seconds, if it is detected that the outlet water temperature is ≤ the water outlet antifreeze temperature point, or the return air pressure is detected for 10 consecutive seconds and the return air pressure is ≤ 5bar, as long as any one of the conditions is met, the heat pump unit will be controlled to enter Freeze protection mode.

[0064] When in the heating mode, after the compressor is turned on for 30 seconds, when it is detected that the outlet water temperature ≤ the inlet water temperature -2°C, and the outlet water temperature ≤ the outlet water antifreeze temperature point, and the two conditions are met at the same time, the heat pump unit is controlled to enter the antifreeze protection model.

[0065] When in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com