Built-in flushing and cooling valve of hydraulic motor

A hydraulic motor and cooling valve technology, applied in servo motor components, fluid pressure actuating devices, fluid pressure actuating system components, etc., can solve the problems of large hydraulic energy loss, high cost and high oil temperature, and reduce losses , The effect of simplifying installation difficulties, saving energy and environmental protection energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

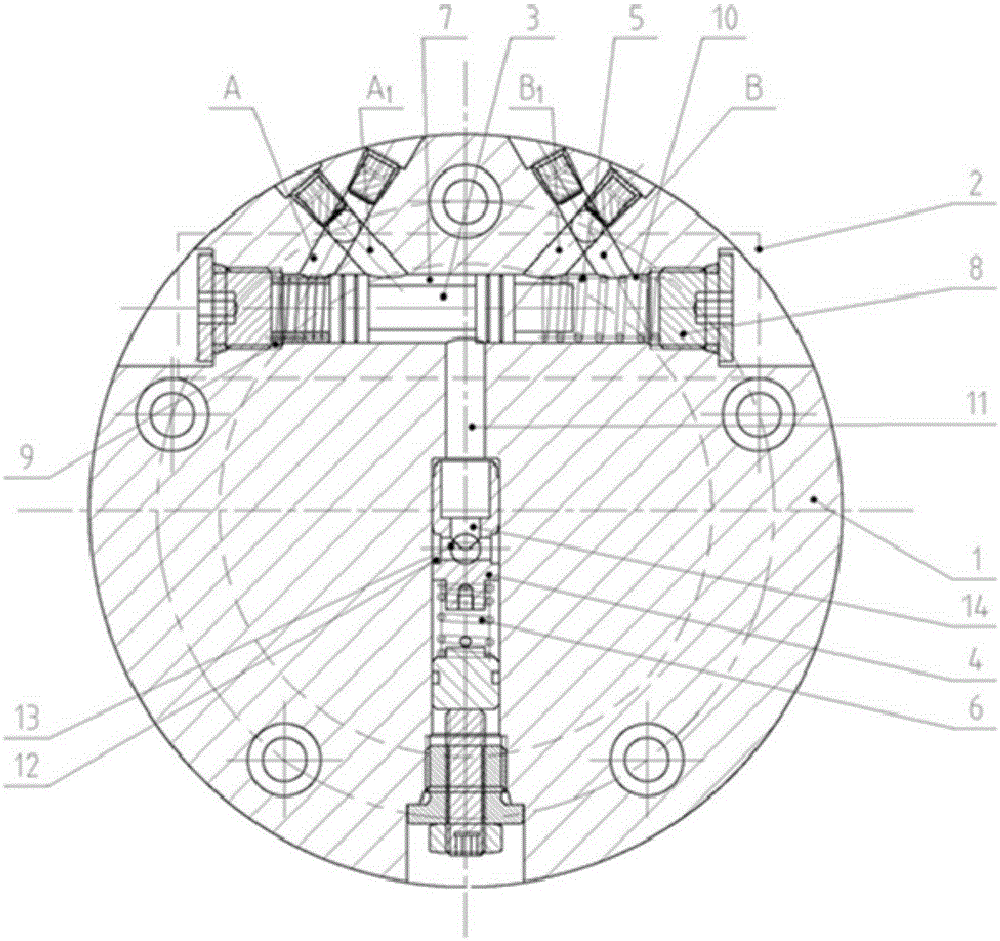

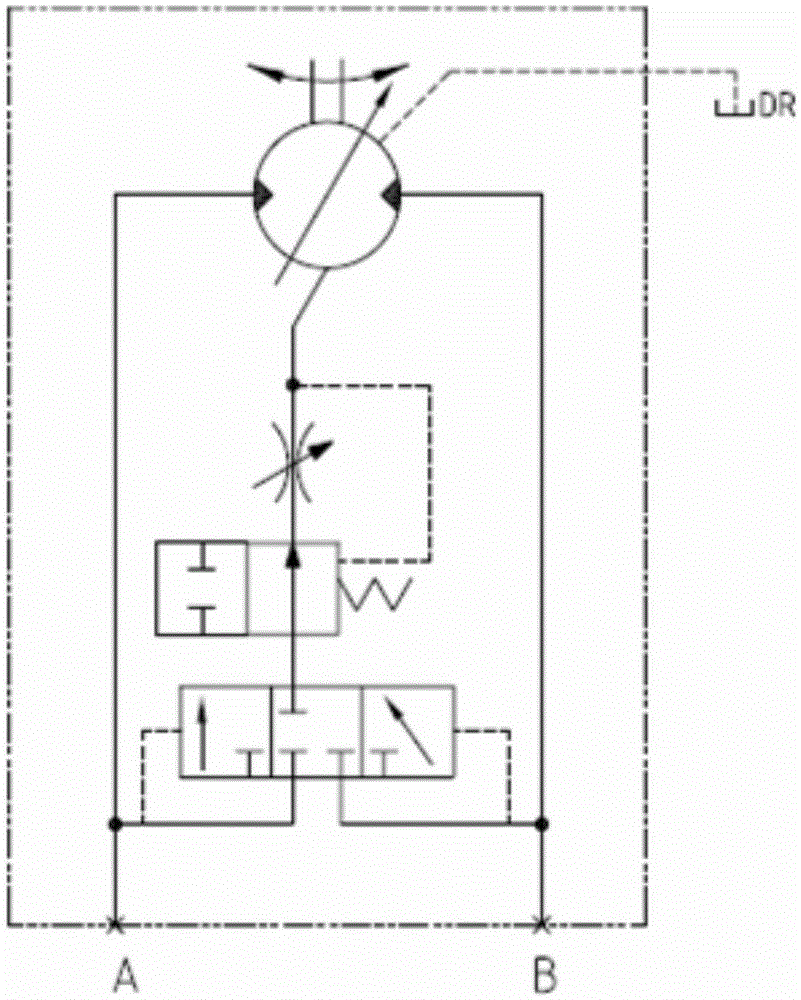

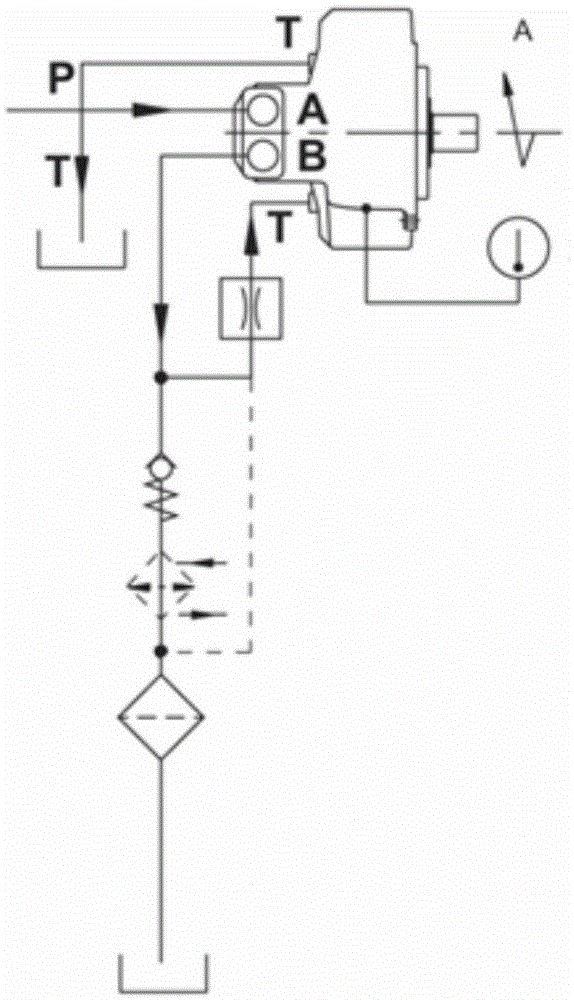

[0021] like figure 1 and 2 As shown, a flushing and cooling valve with a built-in hydraulic motor includes a valve body 1, wherein the valve body 1 includes a two-way variable pump 2, a first valve core 3, a second valve core 4, a first spring 5 and a second valve core. Two springs 6, the two-way variable pump 2 is connected to the oil inlet of the hydraulic motor, the first spool 3 has a cavity 7 in the middle, and the second spool 4 is set at the lower end of the first spool 3 , there is an oil chamber 11 between the first spool 3 and the second spool 4, and the oil chamber 11 communicates with the concave cavity 7, and the second oil hole 13 and the inner oil of the hydraulic motor are arranged in the oil chamber 11 The cavities communicate with each other. A blind hole 14 is provided in the middle of one end of the second spool 4, and the diameter of the blind hole 14 corresponds to the oil chamber 11. The side of the second spool 4 is provided with a first oil hole 12, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com