Preparation method of fine-denier high-shrinkage composite filament plain weave fabric

A high-shrinkage, composite yarn technology, applied in the processing of textile materials, continuous processing of textile materials, dyeing methods, etc., can solve problems such as uneven fabrics, poor color fastness, and premature shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

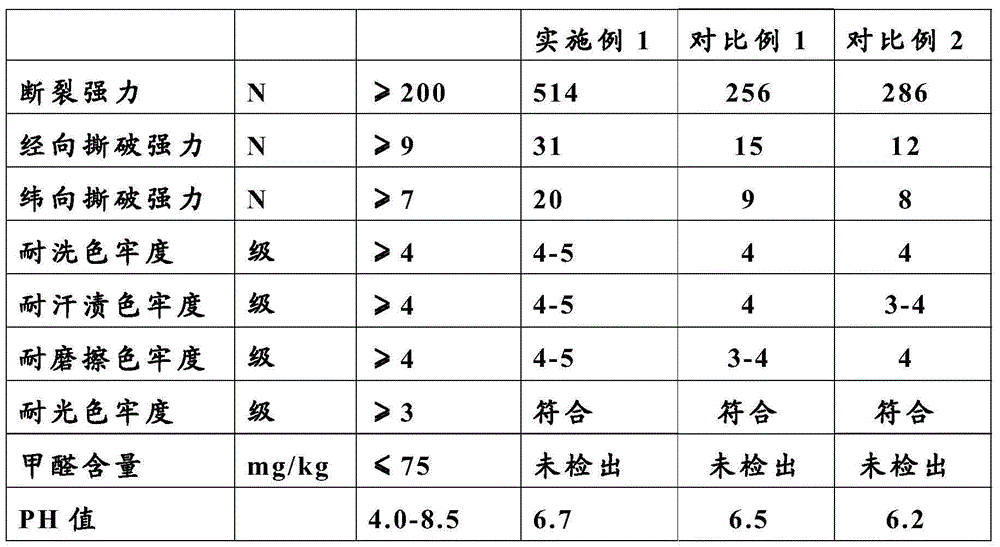

Embodiment 1

[0020] The invention discloses a method for preparing a fine denier high shrinkage composite silk plain weave fabric. The fine denier high shrinkage composite silk plain weave fabric is prepared from raw materials through warping, sizing, weaving, washing with alkali, dyeing, washing, color fixing and shaping.

[0021] Raw material: The raw material is 80D / 156F high-shrinkage cotton-like fiber, purchased from Taicang Jinhui Chemical Fiber Industry Co., Ltd.

[0022] Warping: use Tsudakoma KSH500 pulping and equipment for warping and sizing, and use Tsudakoma KSH500 pulping and equipment hydrostatic pressure device for section warping.

[0023] Sizing: Water-soluble polyester size with a mass concentration of 12% is used for sizing, and the sizing speed of Tsudakoma KSH500 type sizing equipment is controlled to 220m / min, the rear oiling roller is 10r / min, and the silk output tension is 11kg, coiling tension is 15kg, draft A=0%, draft B=+1.1%, size tank temperature is 50°C, dryi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com