Laser printing medium, preparation method thereof and coating layers

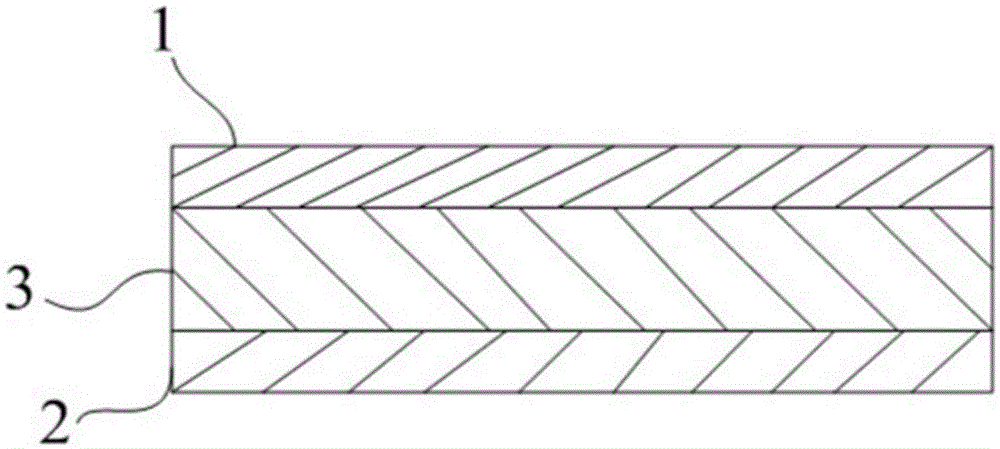

A laser printing and medium technology, applied in the direction of coating, etc., can solve the problems of easy paper jamming and poor printing image quality, and achieve the effect of not easy paper jamming, smooth printing and feeding, and good image color reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The first surface glue formula: (glue A-1)

[0037]

[0038] Add silicon dioxide into deionized water, disperse for 30 minutes with a tooth disc disperser, and the dispersion speed is 1200 rpm, then add ethylene-vinyl acetate copolymer emulsion, anti-sticking agent, antistatic agent, wetting and leveling agent, and stir Mix evenly to prepare coating glue A-1.

[0039] Apply the glue solution on transparent PET (commercially available, manufacturer Hefei Lucky Technology Industry Co., Ltd., model FP1) with a thickness of 100 μm by doctor blade coating method, dry with hot air, the maximum temperature of hot air is 90 ° C, and measure the coating after drying Thickness 12μm.

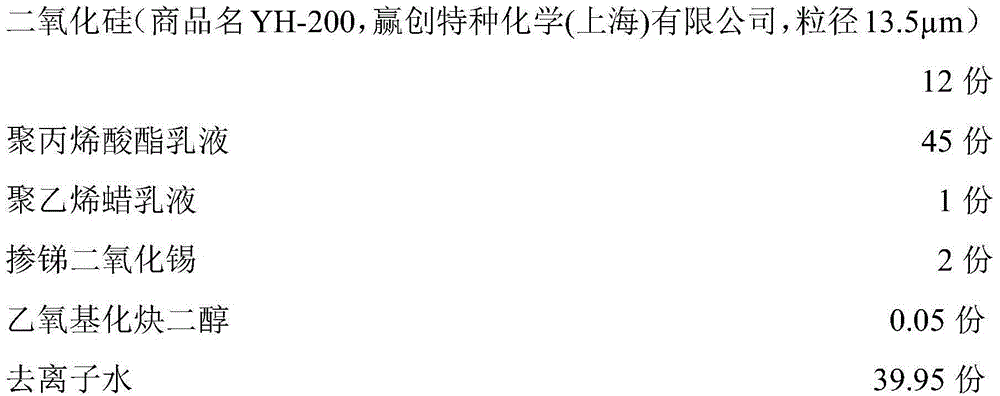

[0040] Second surface glue formula: (glue B-1)

[0041]

[0042] The preparation method is the same as glue A-1, and glue B-1 is obtained. Apply the same coating and drying method to the other side that has been coated with glue A-1, and measure the thickness of the coating to 15 μm after d...

Embodiment 2

[0045] The first surface glue formula: (glue A-2)

[0046]

[0047] Prepare the glue A-2 in the same way, apply the glue on one side of the white PVC material with a thickness of 250 μm by doctor blade coating, and obtain a coating with a thickness of 10.5 μm after drying.

[0048] Second surface glue formula: (glue B-2)

[0049] Use silica (SD-621, Beijing Aerospace Saide Technology Development Co., Ltd., particle size 13 μm) to replace the silica YH-200 in the glue B-1, and use water-based polyurethane to replace the polyacrylic acid in the glue B-1 The ester emulsion was coated in the same way to obtain a coating with a thickness of 16 μm.

[0050] After both sides are all coated, make printing medium 2, measure its performance (see table 1)

Embodiment 3

[0052] The first surface glue formula: (glue A-3)

[0053]

[0054]

[0055] Second surface glue formula: (glue B-3)

[0056]

[0057] According to the same method as in Example 1, the two surfaces of white PET with a thickness of 150 μm were coated respectively to prepare printing medium 3, and its properties were measured (see Table 1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com