Tension control device

A tension control and tension adjustment device technology, applied in the directions of transportation and packaging, conveying filamentous materials, thin material processing, etc., can solve the problems of variability of spindles, poor molding, increase production costs, etc., and achieve easy operation and simple structure. , the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

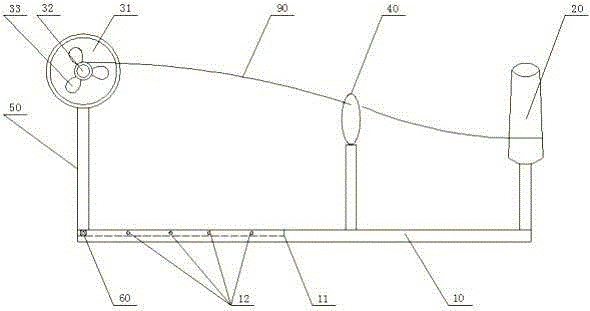

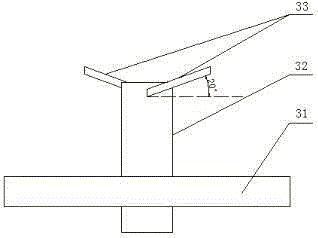

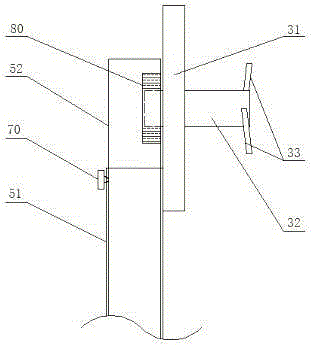

[0013] Below in conjunction with accompanying drawing, the present invention will be further described:

[0014] like Figure 1 to Figure 3 As shown, the present invention includes a creel 10 on which the winding 20 can be placed at one end, and a tension regulating device is provided at the other end of the creel 10, and the yarn 90 passes through the yarn guide hook 40 arranged on the creel 10 through the tension regulating device. Wrapped on the bobbin 20, the tension regulating device includes a disc 31 which is rotatably arranged on the creel 10, and the disc 31 is axially connected with a rotating shaft 32 for contacting the yarn 90, and the tension regulating device is installed on the creel 10. The height is adjustable, and the distance between the tension adjusting device and the yarn guide hook 40 is adjustable. Under the traction, the yarn 90 rotates at a high speed and retreats from the silk cake. Under the action of centrifugal force, air resistance and the cohes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com