Cloth flattening device

A flattening device and cloth technology, which can be used in thin material handling, transportation and packaging, spreading thin soft materials, etc., can solve problems such as poor spreading effect, and achieve simple structure, convenient use, and excellent cloth spreading effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In the following, the present invention will be further explained through specific embodiments in conjunction with the drawings:

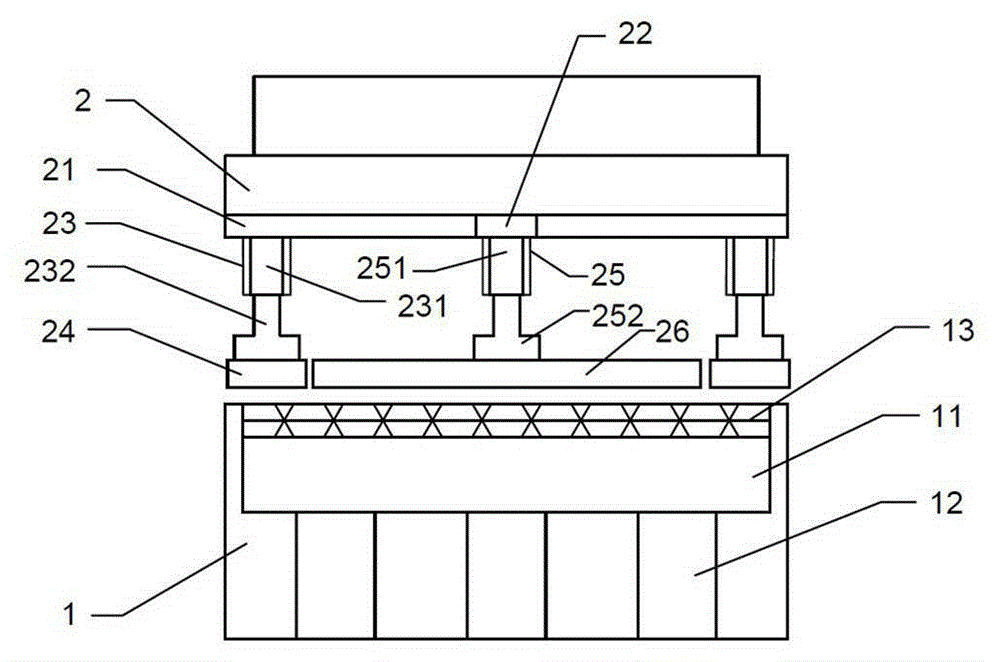

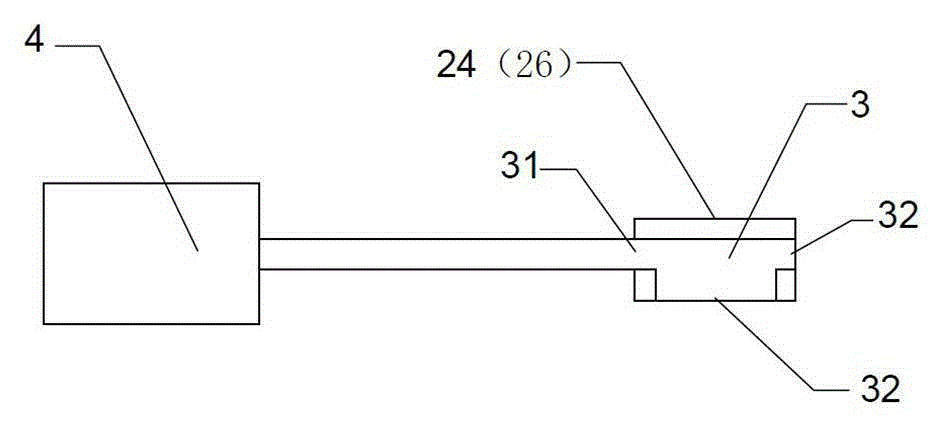

[0015] see figure 1 , figure 2 , A cloth flattening device, comprising a spreading table 1, and a mounting top base 2 located above the spreading table 1. The mounting top base 2 is provided with a first displacement path 21, a second displacement path 22, and The first cloth flattening mechanism that moves along the first displacement path 21 and the second cloth flattening mechanism that moves along the second displacement path 22, the first and second cloth flattening mechanisms are also provided with blowing mechanisms , The spreading table 1 is provided with a suction mechanism that cooperates with the blowing mechanism. The first displacement path 21 is provided along the length direction of the spreading table 1, and the second displacement path 22 is provided along the width direction of the spreading table 2.

[0016] The first cloth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com