Tobacco stereoscopic warehouse conveyor and conveying method thereof

A three-dimensional warehouse and conveyor technology, which is applied in the field of tobacco logistics and warehousing, can solve the problems of high energy consumption and low work efficiency of conveyors, and achieve the effects of improving transportation efficiency, reducing energy consumption and rational system structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

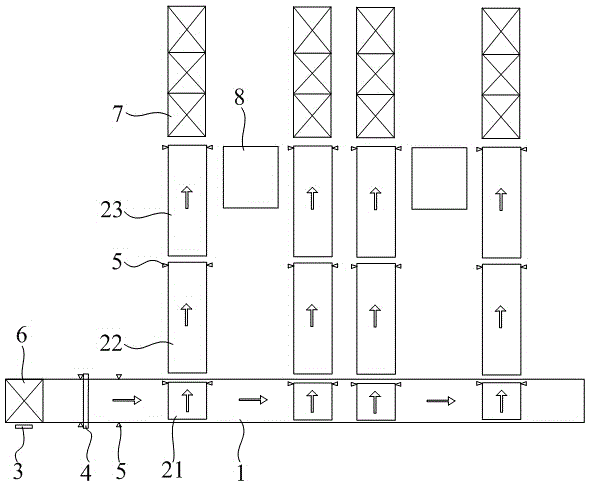

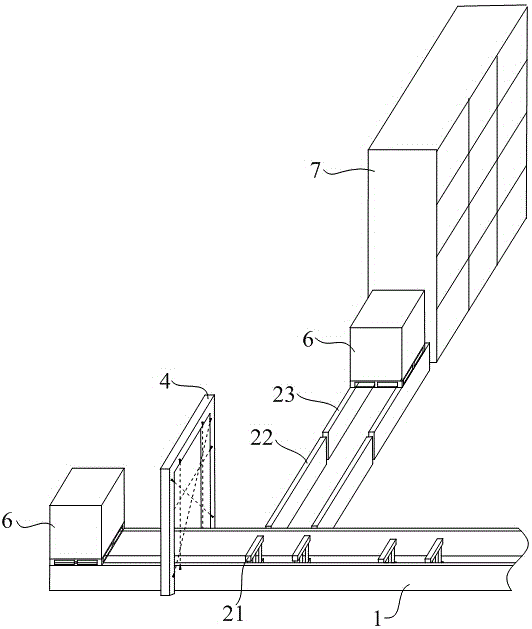

[0018] Embodiment one: if figure 1 and figure 2 As shown, a tobacco three-dimensional warehouse conveyor includes a horizontal conveyor 1, a vertical conveyor 2 and a control center. The horizontal conveyor 1 and the vertical conveyor 2 are equipped with a plurality of photoelectric switches for detecting the position of the stack 5. The main controller of the control center is a PLC controller. Both the horizontal conveyor 1 and the vertical conveyor 2 include two parallel rails and double-row chains installed on the rails, and the chains are driven by rotating shafts to transport the cigarette stacks 6 . The entrance end of the transverse conveyor 1 is provided with a code scanner 3, which scans the barcode on the tray at the bottom of the cigarette stack 6 and transmits it to the control center, and the control center can obtain the matching cigarette stack 6 information, Including destination address, cigarette brand, cigarette weight, production date and other extended...

Embodiment 2

[0021] Embodiment 2: A tobacco three-dimensional warehouse transportation method, which is applied to the warehouse conveyor described in Embodiment 1, and includes the following steps,

[0022] a. The stack of cigarettes 6 neatly stacked on the pallet is placed on the horizontal track by the forklift, the barcode on the pallet is scanned by the scanner 3 and transmitted to the control center, and the control center extracts the pre-stored target address information and controls the operation of the conveyor.

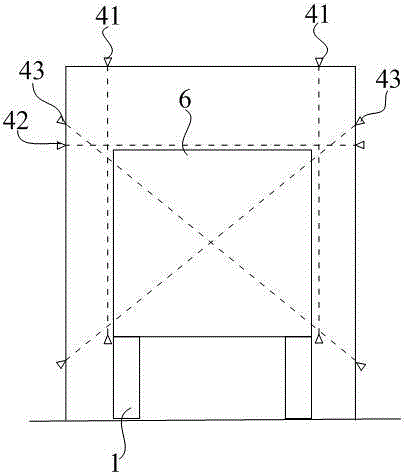

[0023] b. The horizontal conveyor 1 is running, the photoelectric switch 5 detects that the smoke stack 6 reaches the shape detection device 4, two sets of vertical photoelectric switches 41 and horizontal photoelectric switches 42 detect the left and right sides and height of the smoke stack 6, and two sets of oblique photoelectric switches 43 detect the smoke stack 6 front, and signal transmission to the control center; cigarette stack 6 continues to move forward, when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com