Rotating clamping type wine bottle sealing cover structure

A sealing cap and screw-on type technology, which is applied in the field of wine sealing structure, can solve the problems of increasing cost and reducing efficiency, and achieves the effects of convenient processing, high assembly efficiency and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

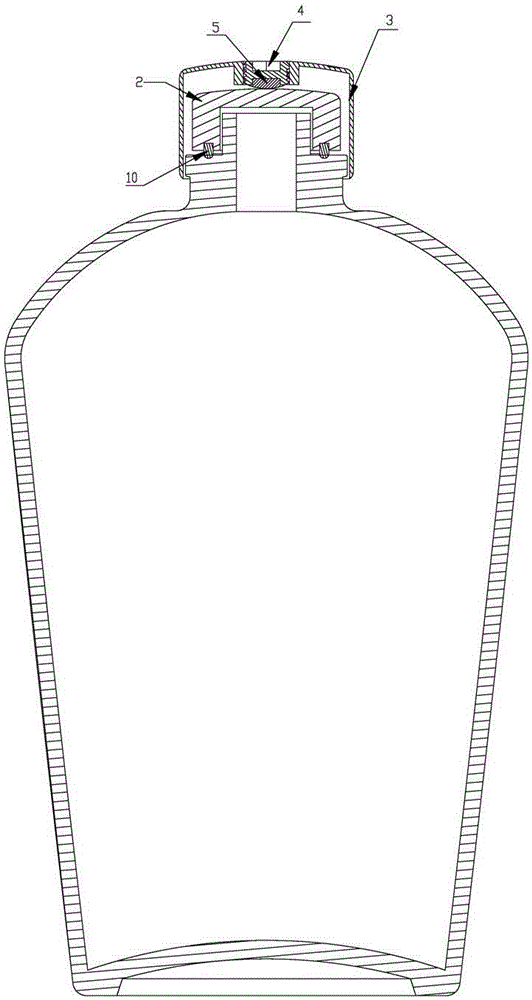

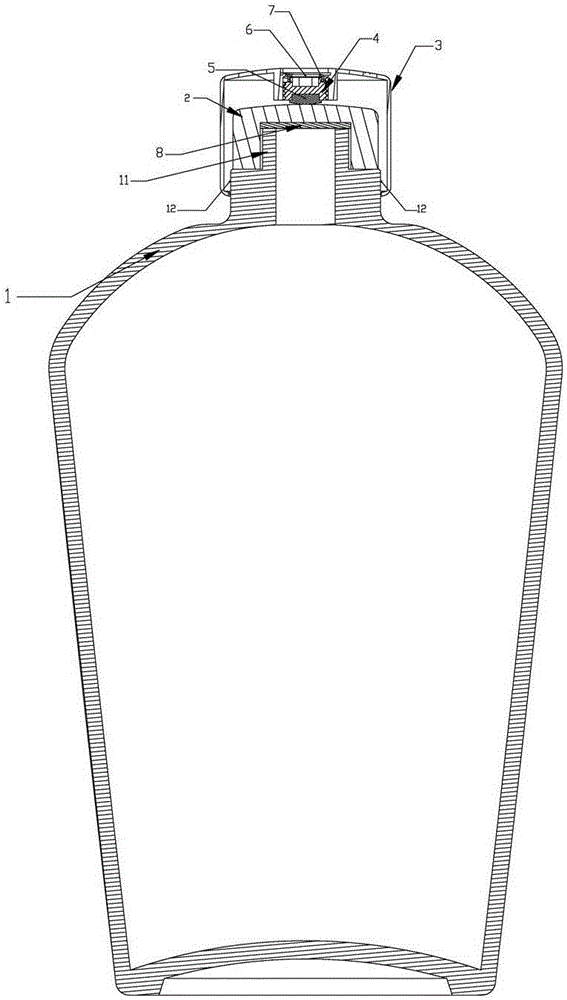

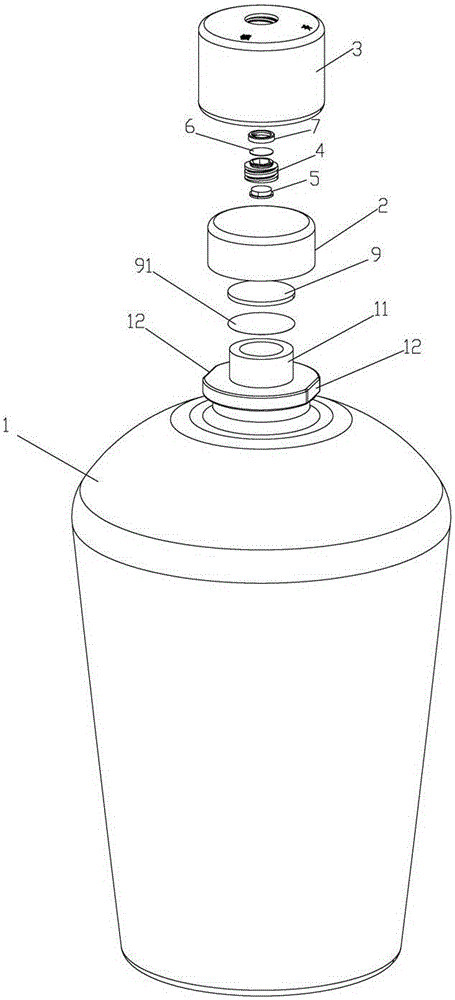

[0017] Such as Figure 1-5 As shown, a screw-type wine bottle sealing cover structure includes a wine bottle body 1, a ceramic cover body 2 and a compression cover 3, and an annular boss 11 is provided on the top of the opening of the wine bottle body 1, The ceramic cover 2 cooperates with the annular boss 11 and surrounds the annular boss 11, cuts out two plane-parallel notches 12 on both sides of the outer diameter of the bottle mouth, and is provided with a corresponding notch 12 on the inner side of the lower edge of the compression cover 3. Two barbs 31, the compression cover 3 is installed on the ceramic wine bottle and rotated at an appropriate angle, and the two barbs 31 on the lower edge of the compression cover 3 will hook the mouth of the ceramic wine bottle. There is a screw hole on the top of the cover 3, and a compression screw 4 is arranged in the screw hole, and a plastic pad 5 is arranged at the bottom of the compression screw 4, and the compression screw 4 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com