Automatic leveling and distance-measuring plate shearer set and control method thereof

An automatic leveling and leveling machine technology, applied in the direction of manufacturing tools, feeding devices, positioning devices, etc., can solve the problems of imperfect adjustment, low leveling precision, poor consistency, etc., and achieve reliable automation and leveling efficiency High, leveling precision and fast results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

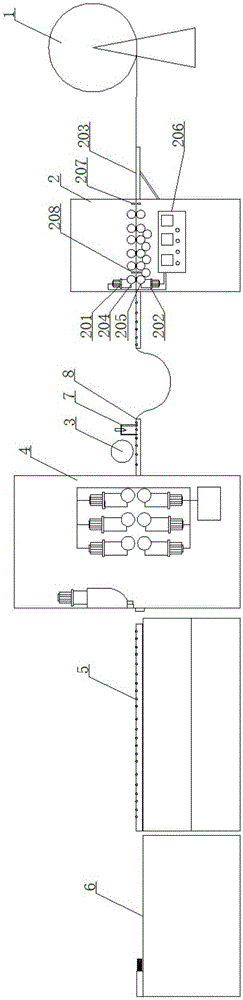

[0048] Such as figure 1 As shown, the automatic leveling and distance measuring shearing unit includes an unwinding machine 1, a primary leveling machine 2, a distance measuring roller 3, a secondary leveling and shearing machine 4, a conveyor belt 5, a receiving machine 6, a probe module 7 and Transition conveyor belt 8, described unwinding machine 1, primary leveling machine 2, transition conveyor belt 8, secondary leveling machine 4, conveyor belt 5 and material receiving machine 6 are sequentially connected, and described probe module 7 and distance measuring roller 3 sequentially arranged above the transition conveyor belt 8;

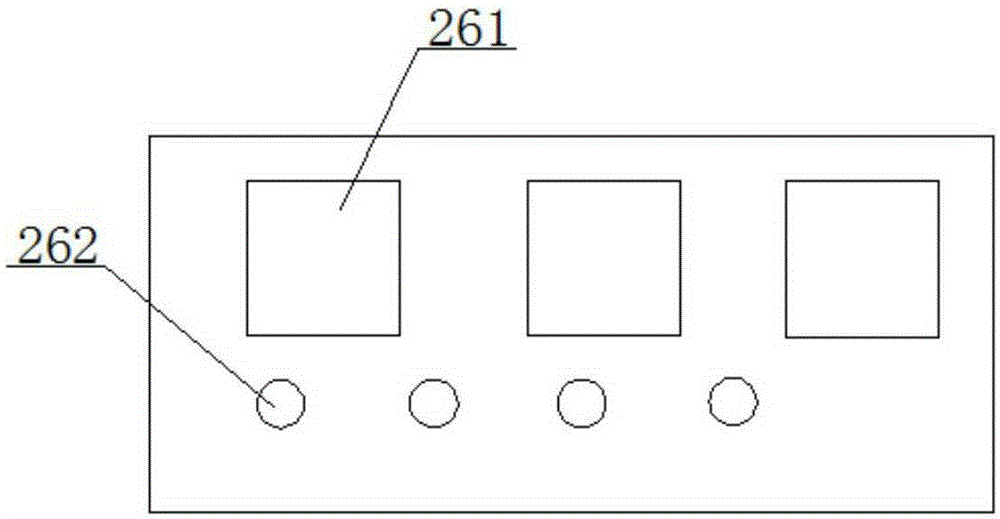

[0049] Such as figure 2 , image 3 As shown, the primary leveling machine 2 includes an inlet pallet 203, an upper leveling roller 204 and a lower leveling roller 205, and also includes an upper leveling roller motor 201 and a lower leveling roller motor 202, and the upper leveling roller motor 201 lowers the leveling roller The flat roller mot...

Embodiment 2

[0066] Such as figure 1 As shown, the automatic leveling and distance measuring shearing unit includes an unwinding machine 1, a primary leveling machine 2, a distance measuring roller 3, a secondary leveling and shearing machine 4, a conveyor belt 5, a receiving machine 6, a probe module 7 and Transition conveyor belt 8, described unwinding machine 1, primary leveling machine 2, transition conveyor belt 8, secondary leveling machine 4, conveyor belt 5 and material receiving machine 6 are sequentially connected, and described probe module 7 and distance measuring roller 3 sequentially arranged above the transition conveyor belt 8;

[0067] Such as figure 2 , image 3 As shown, the primary leveling machine 2 includes an inlet pallet 203, an upper leveling roller 204 and a lower leveling roller 205, and also includes an upper leveling roller motor 201 and a lower leveling roller motor 202, and the upper leveling roller motor 201 lowers the leveling roller The flat roller mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com