A kind of hollow fiber nanofiltration membrane and preparation method thereof

A nanofiltration membrane and fiber technology, applied in the field of hollow fiber nanofiltration membrane and its preparation, can solve the problems of poor backwash resistance and oxidation resistance, and achieve the effect of high selective separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

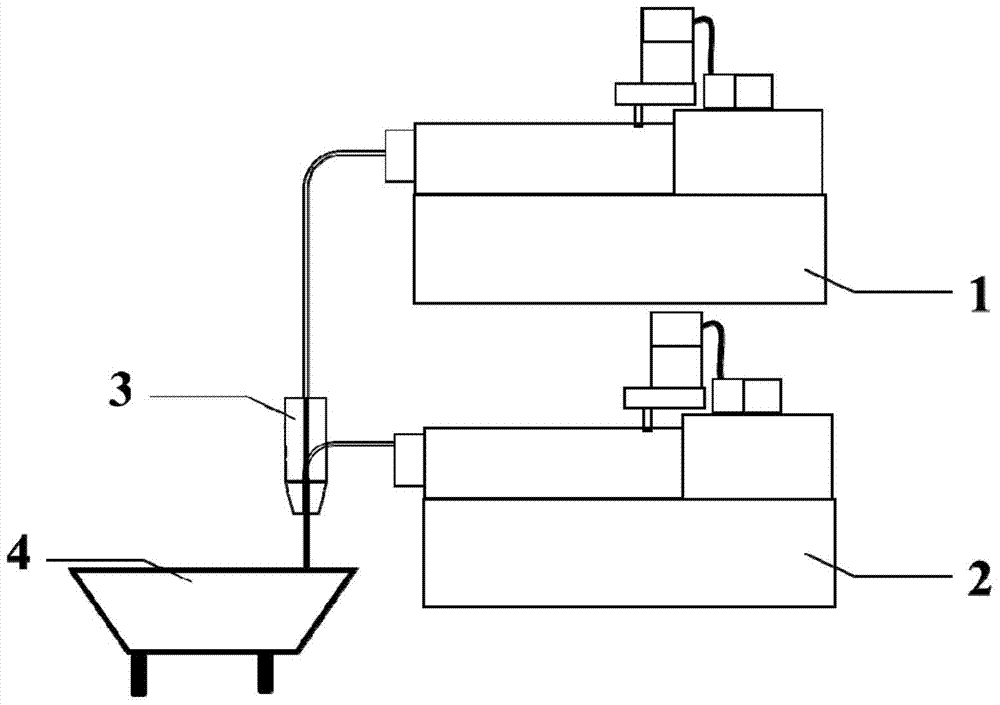

Method used

Image

Examples

Embodiment 1

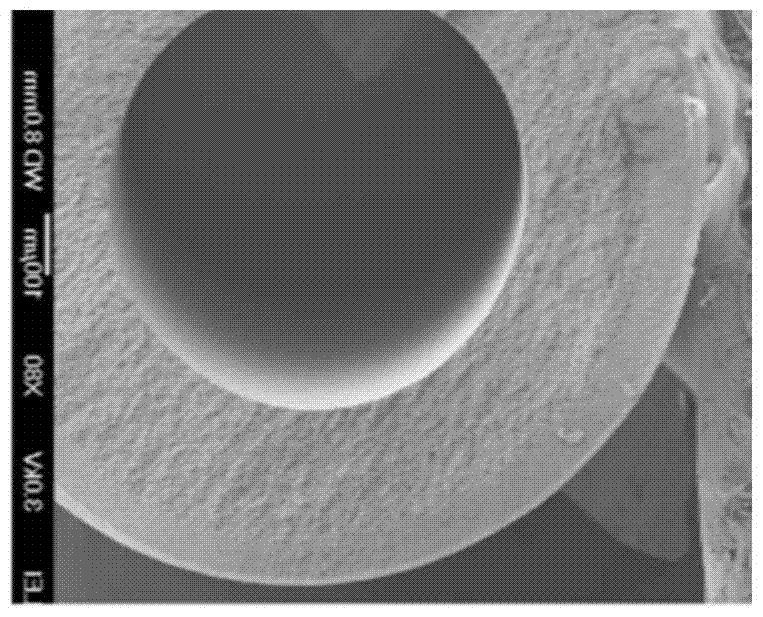

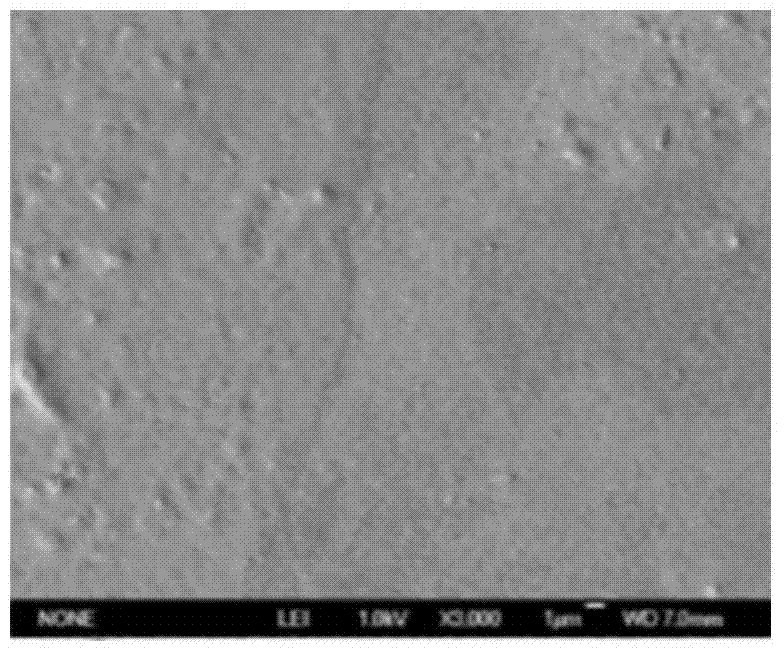

[0034] Polysulfone, tributyl phosphate and cetyl alcohol are used as the outer layer casting solution, and its components are 28wt.% by mass of polysulfone, 36wt.% by mass of tributyl phosphate, and 36wt.% by mass of cetyl alcohol. .%, with polypropylene, tributyl phosphate and lauryl alcohol as the inner layer casting solution, its components are 32wt.% by mass of polypropylene, 58wt.% by mass of tributyl phosphate, and cetyl alcohol by mass The percentage is 10wt.%, respectively added to a co-rotating twin-screw extruder for dissolution and defoaming to obtain a homogeneous casting solution. The polymer homogeneous casting solution is injected into the outer gel medium through the hollow fiber spinneret through the melt pump and the inner gel medium at the same time to solidify to obtain as-spun filaments. The diluent in the as-spun silk is removed by using an extractant to obtain a hollow fiber nanofiltration membrane. The detailed preparation parameters and the structure ...

Embodiment 2

[0036] Polyethersulfone, methyl salicylate and triethylene glycol are used as the outer casting solution, and its components are 24wt.% by mass of polyethersulfone, 71wt.% by mass of methyl salicylate, triethylene glycol Glycol mass percent is 5wt.%, polysulfone, methyl salicylate and ethylene glycol are used as inner layer casting liquid, and its component is that polysulfone mass percent is 28wt.%, and methyl salicylate mass percent is 62wt.%, ethylene glycol mass percentage is 10wt.%, respectively added to the co-rotating twin-screw extruder for dissolution and defoaming to obtain a homogeneous casting solution. The polymer homogeneous casting solution is injected into the outer gel medium through the hollow fiber spinneret through the melt pump and the inner gel medium at the same time to solidify to obtain as-spun filaments. The diluent in the as-spun silk is removed by using an extractant to obtain a hollow fiber nanofiltration membrane. The detailed preparation paramet...

Embodiment 3

[0038] Sulfonated polysulfone, trioctyl phosphate and triethylene glycol are used as the outer layer casting solution, and its components are 20wt.% by mass of sulfonated polysulfone, 75wt.% by mass of trioctyl phosphate, triethylene glycol The mass percentage of diol is 5wt.%, and polyethersulfone, trioctyl phosphate and diethylene glycol are used as the inner layer casting solution, and its components are 32wt.% of polysulfone, and methyl salicylate. 64wt.%, ethylene glycol mass percentage is 4wt.%, respectively added to the co-rotating twin-screw extruder for dissolution and defoaming, to obtain a homogeneous casting solution. The polymer homogeneous casting solution is injected into the outer gel medium through the hollow fiber spinneret through the melt pump and the inner gel medium at the same time to solidify to obtain as-spun filaments. The diluent in the as-spun silk is removed by using an extractant to obtain a hollow fiber nanofiltration membrane. The detailed prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com