Fire fighting truck telescopic boom structure

A technology of telescopic structure and telescopic arm, which is applied in hoisting devices, fire rescue, etc., and can solve problems such as unsupportable, long overall telescopic time, and limited carrying capacity of aerial ladders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

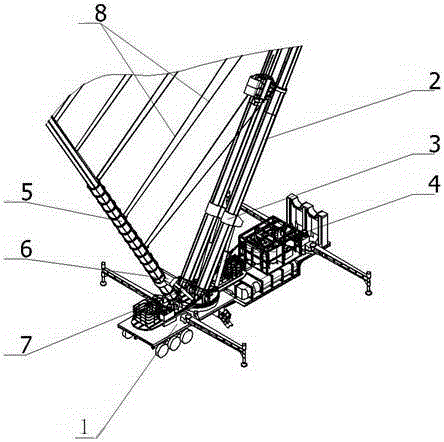

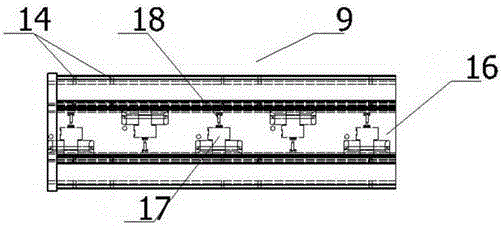

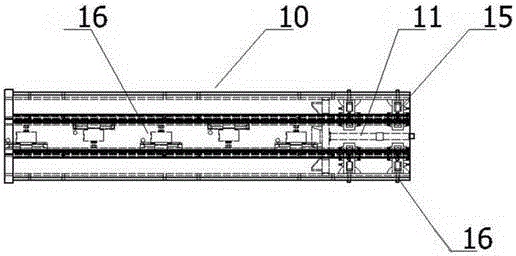

[0013] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as figure 1 , figure 2 , image 3 , Figure 4 Shown: a fire truck telescopic arm structure, including a car body 1, two symmetrically arranged telescopic arms 2 are hinged on the car body 1, and double sleeves 3 are connected outside the two telescopic arms 2, and the double sleeves The cylinder 3 can slide along the axial direction of the telescopic arm 2, the double sleeve 3 is hinged to the working end of the telescopic arm cylinder 4, and the bottom end of the cylinder part of the telescopic arm cylinder 4 is hinged to the vehicle body 1 On the car body 1, the cable arm 5 corresponding to the telescopic arm 2 is also hinged, and the sleeve 6 is connected outside the cable arm 5, and the sleeve 6 can slide along the axial direction of the cable arm 5. The tube 6 is hinged with the working end of the cable arm cylinder 7, and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com