Handrail of walk-behind harvester

A harvester and walk-behind technology, which is applied in the field of parts of walk-behind harvesters, can solve the problems of limited installation position of an air intake pipe, small power installation space, etc., and achieves low cost, small structural changes, and increased air intake area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

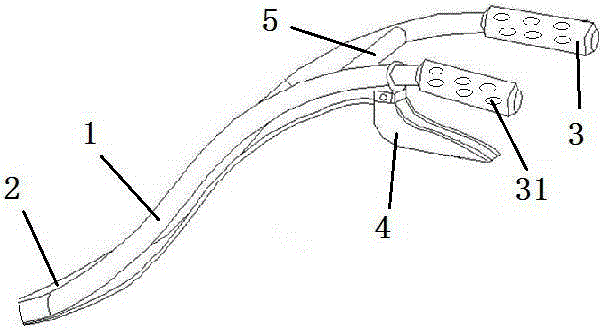

[0016] like figure 1 Shown, the armrest of walk-behind harvester of the present invention comprises armrest seat, and armrest seat is fixed on the frame. A handrail branch pipe 1 is fixed on the handrail seat, and the handrail branch pipe 1 is a hollow metal tube, which is generally made by bending a stainless steel pipe. There are two handrail branch pipes 2, which are combined to form a handrail main pipe 2, so that the interior of the handrail main pipe 2 and the handrail branch pipe 1 are the same, forming a structure similar to a three-way pipe. The end of handrail main pipe 2 is sleeved with a corrugated pipe, and this corrugated pipe communicates with the intake pipe of the engine installed on the harvester support. The end cover of armrest branch pipe 1 is provided with an armrest cover 3, and armrest cover 3 is made of rubber material, and is processed with annular anti-skid line on armrest cover 3, prevents the phenomenon that slipping occurs when using. All have a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com