Method for measuring boiler dry flue gas volume based on coal caloric values and exhaust fume oxygen amount

A technology of coal-fired calorific value and dry flue gas volume, applied in the field of soft measurement, can solve the problem that power plants do not have the analysis of coal-fired components and elements, and achieve the effects of avoiding harsh requirements, simplifying the calculation model, and meeting online calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

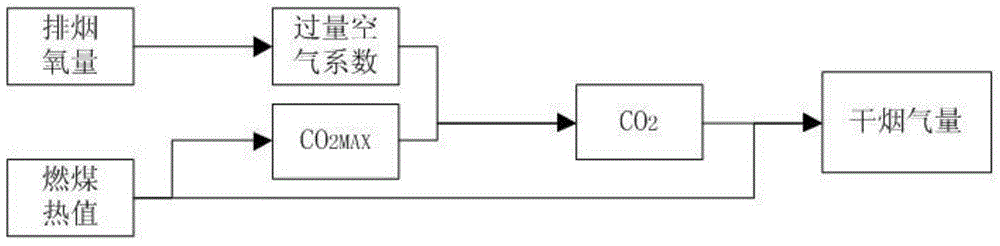

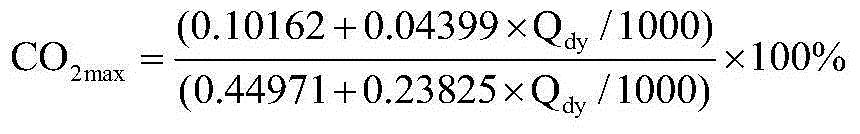

[0024] Such as figure 1 Shown is a method for measuring the amount of boiler dry flue gas based on the calorific value of coal combustion and the amount of exhaust gas oxygen. The calorific value of coal combustion, the excess air coefficient is calculated according to the exhaust gas oxygen amount, and the CO is calculated according to the coal calorific value 2 Theoretical maximum; based on stated excess air factor and CO 2 The theoretical maximum is calculated to get CO 2 content in dry flue gas, according to the CO 2 The content in the dry flue gas and the calorific value of coal combustion are calculated to obtain the volume and quality of the dry flue gas.

[0025] In the present invention, taking a 1000MW boiler as an example, the detailed steps for measuring the amount of dry flue gas are as follows:

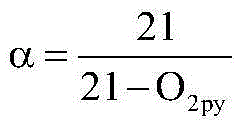

[0026] Step 1: Obtain the exhaust gas oxygen amount O ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com