Cylindrical first-order buoyancy magnetic liquid acceleration sensor

An acceleration sensor, magnetic liquid technology, applied in the direction of measuring acceleration, speed/acceleration/impact measurement, instruments, etc., can solve the problems of difficult flow of magnetic liquid, low viscous energy consumption efficiency, fragile permanent magnet, etc. Effects of linearity and sensitivity, resolving fragmentation problems, avoiding flow difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described with accompanying drawing as specific embodiment:

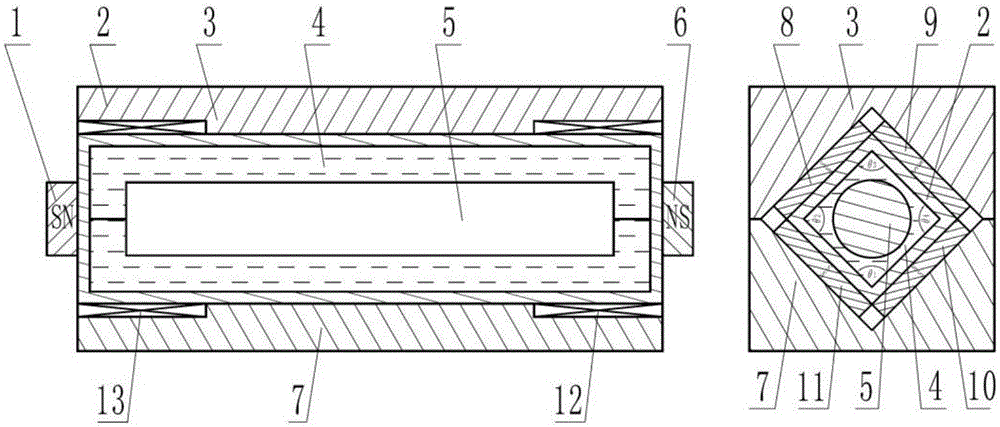

[0021] A cylindrical first-order buoyancy magnetic liquid acceleration sensor, such as figure 1 , the damping device includes: a first limit permanent magnet 1, a housing 2, an upper V-shaped armature 3, a magnetic liquid 4, a mass 5, a second limit permanent magnet 6, a lower V-shaped armature 7, a first suspension Permanent magnet 8 , second suspended permanent magnet 9 , third suspended permanent magnet 10 , fourth suspended permanent magnet 11 , second induction coil 12 and first induction coil 13 .

[0022] Connections between the parts making up the device:

[0023] The housing 2 is filled with magnetic liquid 4, and the mass block 5 is loaded into the housing 2; after the housing 2 is sealed, the first limit permanent magnet 1 is fixedly installed on the left end surface of the housing 2, The second limit permanent magnet 6 is fixedly installed on the right end s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com