Pharmaceutical fluidized bed particle diameter distribution online detection device based on differential pressure sampling

A pharmaceutical fluidized bed and detection device technology, applied in the direction of measurement device, particle and sedimentation analysis, particle size analysis, etc., to reduce the introduction of human error and pollution, improve the detection environment, reduce the detection speed and additional cleaning accessories. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Such as figure 1 As shown, the on-line detection device for the diameter distribution of pharmaceutical fluidized bed particles based on differential pressure sampling is installed outside the fluidized bed reaction chamber.

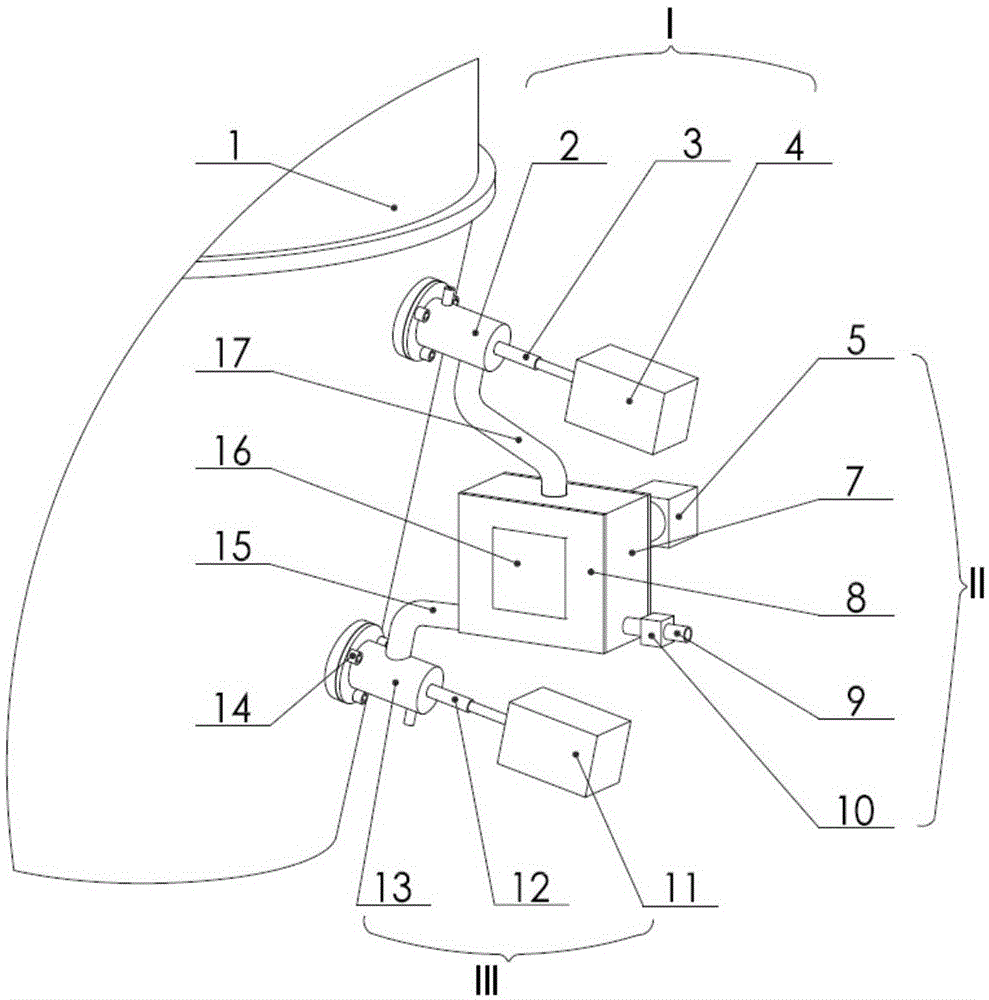

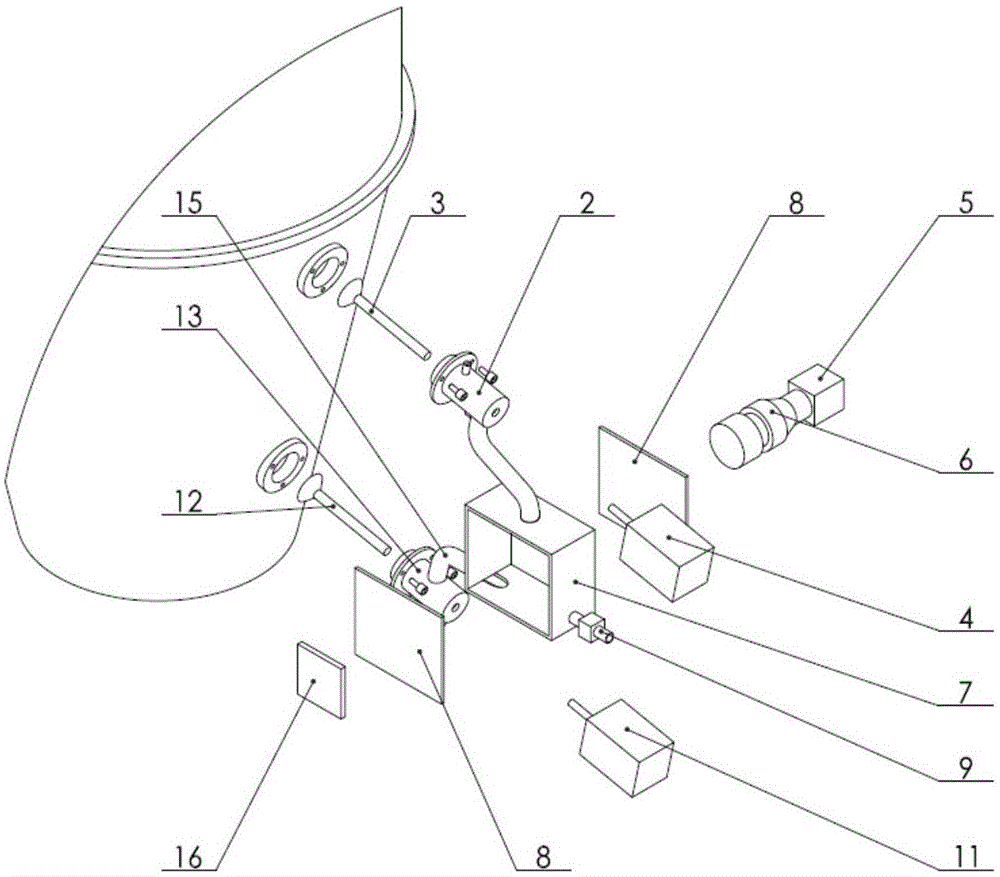

[0047] Such as figure 2 and image 3 As shown, the detection device has a sampling mechanism I, a recovery mechanism II and a detection mechanism III; the inner cavities of the sampling mechanism I, the recovery mechanism II and the detection mechanism III are connected to each other to form a sealed space isolated from the outside world; the sampling mechanism I has a sampling sleeve 2. Sampling piston 3 and sampling pusher 4; a sampling channel is opened on the fluidized bed reaction chamber, and the sampling channel communicates with the inner cavity of the sampling sleeve 2; the sampling piston 3 is composed of a piston rod 31 and a plug 32 (such as Figure 5 As shown), the piston rod 31 is tightly matched with the sampling sleeve 2, the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com