Device and method for suppressing mechanical coupling error of dual-mass silicon microgyroscope

A technology of silicon micro gyroscope and coupling error, which is applied in the field of MEMS and micro inertial measurement, can solve the problems of structural torsion, silicon micro gyroscope performance degradation, follow-up, etc., to reduce the rotation effect, reduce the follow-up effect, reduce effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

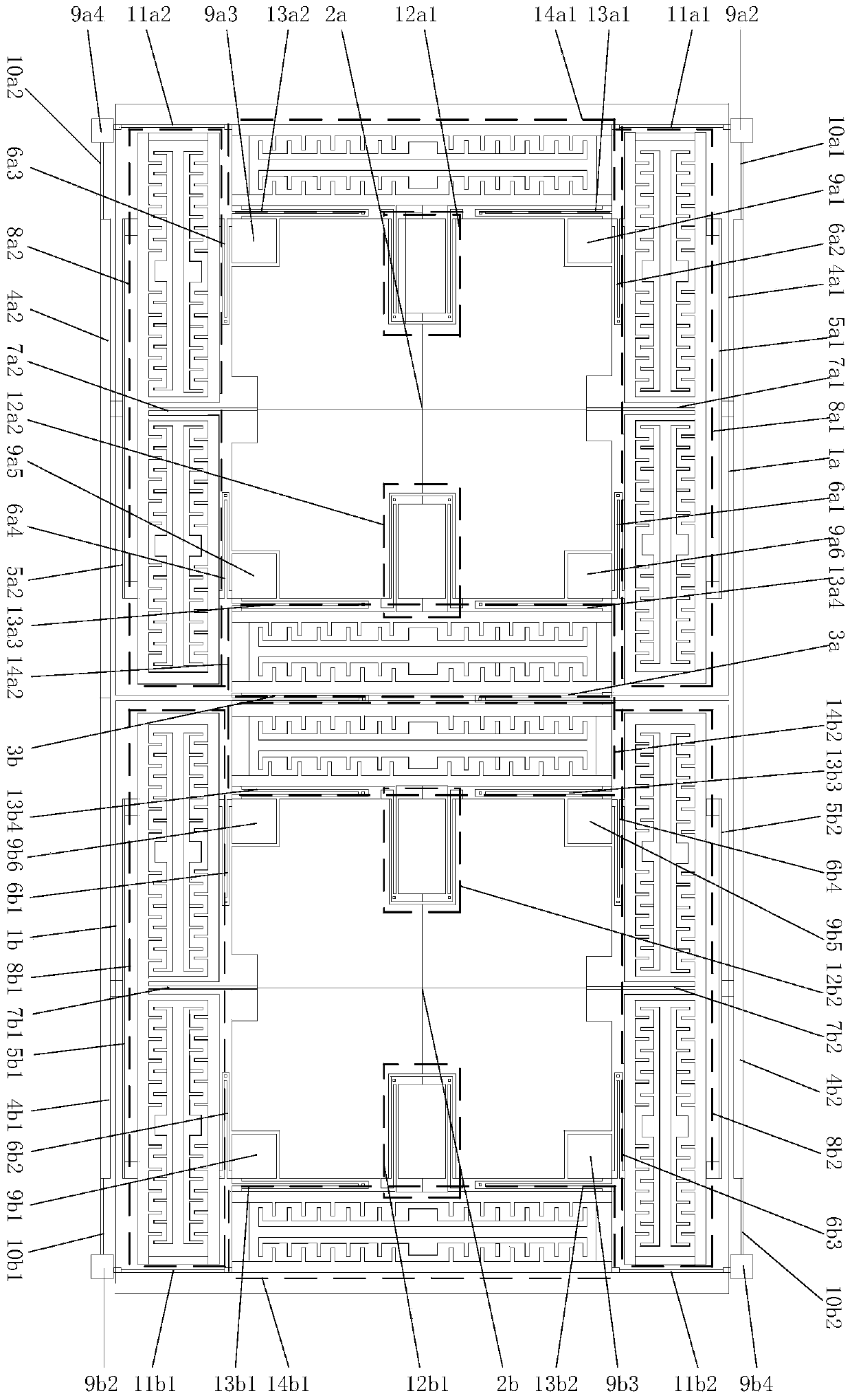

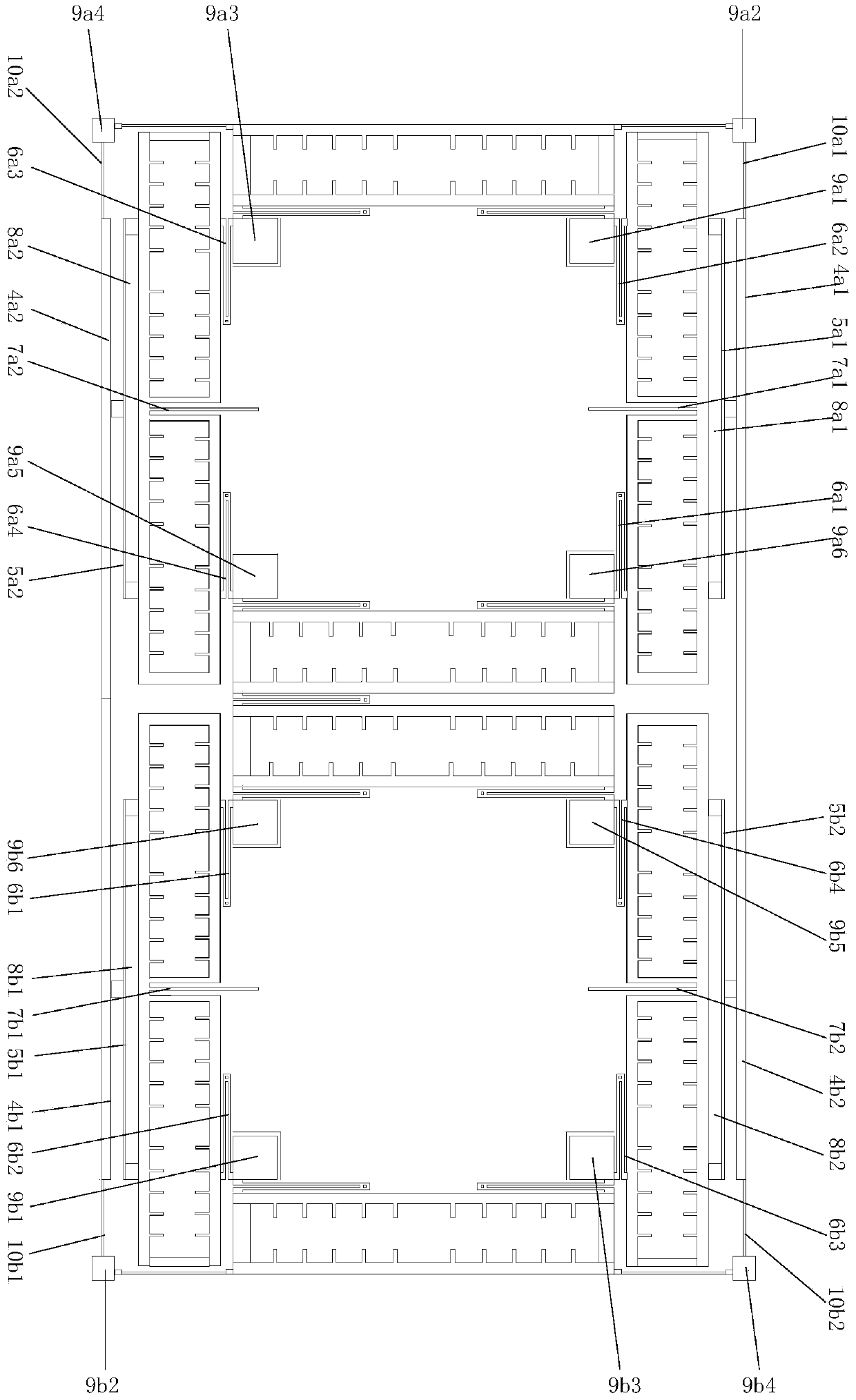

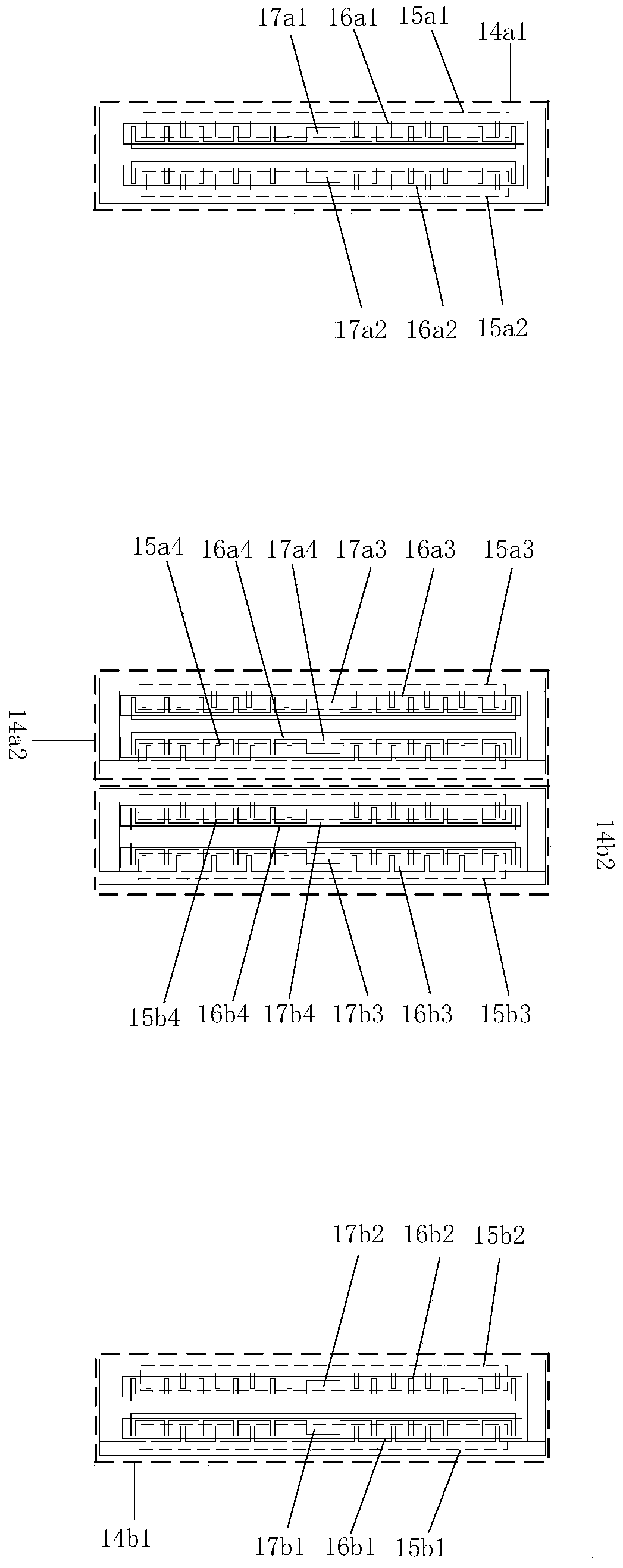

[0022] combined with figure 1 , the mechanical coupling error suppression method and device of the double-mass silicon micro-gyroscope of the present invention realize the measurement of the input angular velocity perpendicular to the x-y horizontal plane. The structure is divided into upper and lower layers, the upper layer is the vibrating mechanical structure of the silicon micro gyroscope, and the lower layer is the glass substrate adhered with signal leads. The mechanical structure of the gyroscope is composed of two symmetrically placed identical single-mass angular velocity measurement unit substructures 1a and 1b; in the driving mode, the two single-mass angular velocity measurement unit substructures are driven by coupling folded beams 3a and 3b Establish association, in the detection mode, establish association through beams 4a1, 4b1, 4a2, 4b2, beams 4a1, 4b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com