Rubber tube mark printing system based on computer control

A computer and rubber tube technology, applied to the general parts of printing machinery, printing, printing machines, etc., can solve the problems of pigments mixing with each other, achieve the effects of reducing heating, increasing service life, and ensuring the printing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

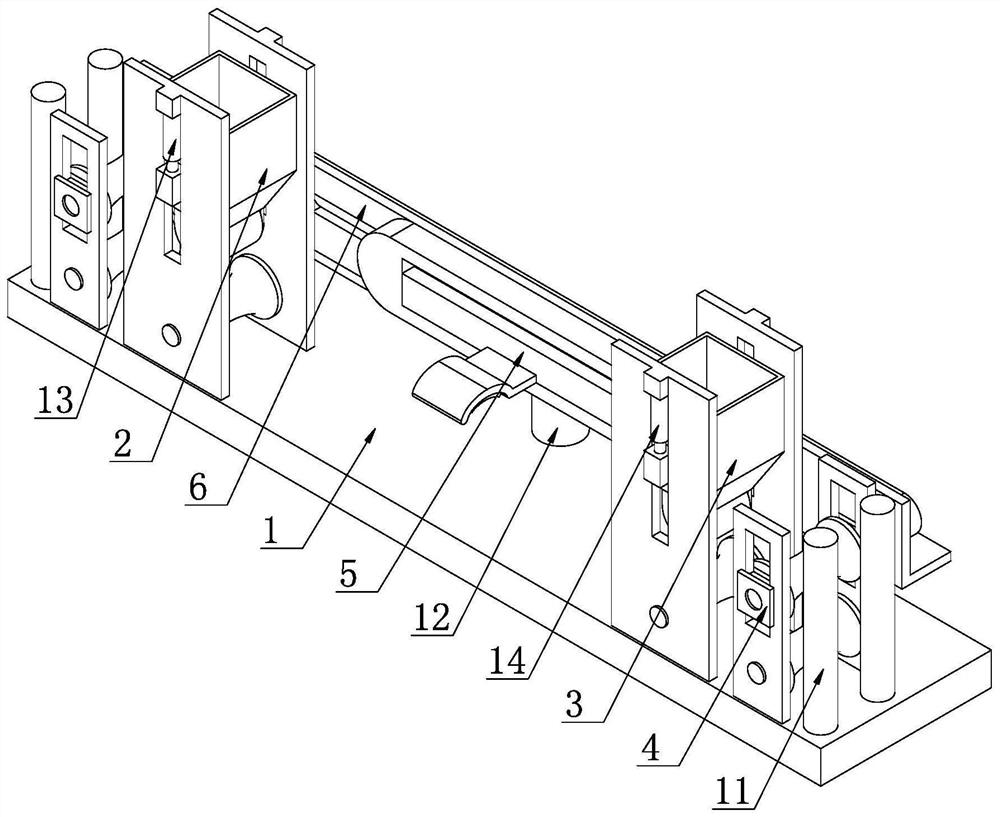

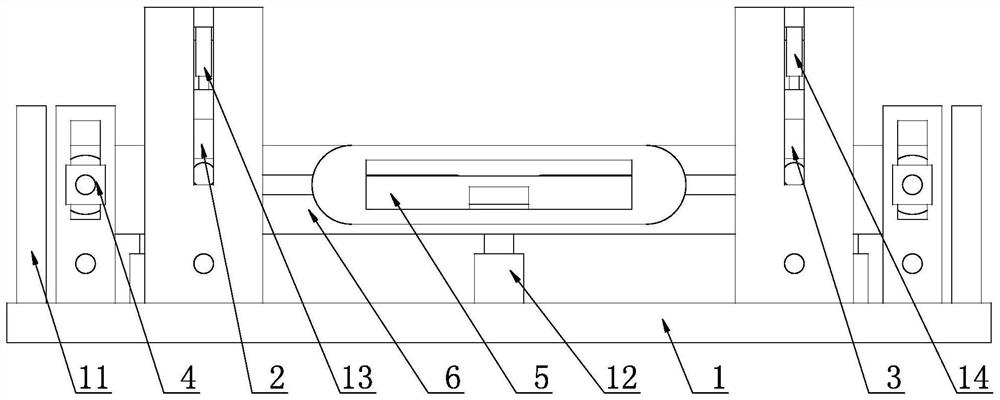

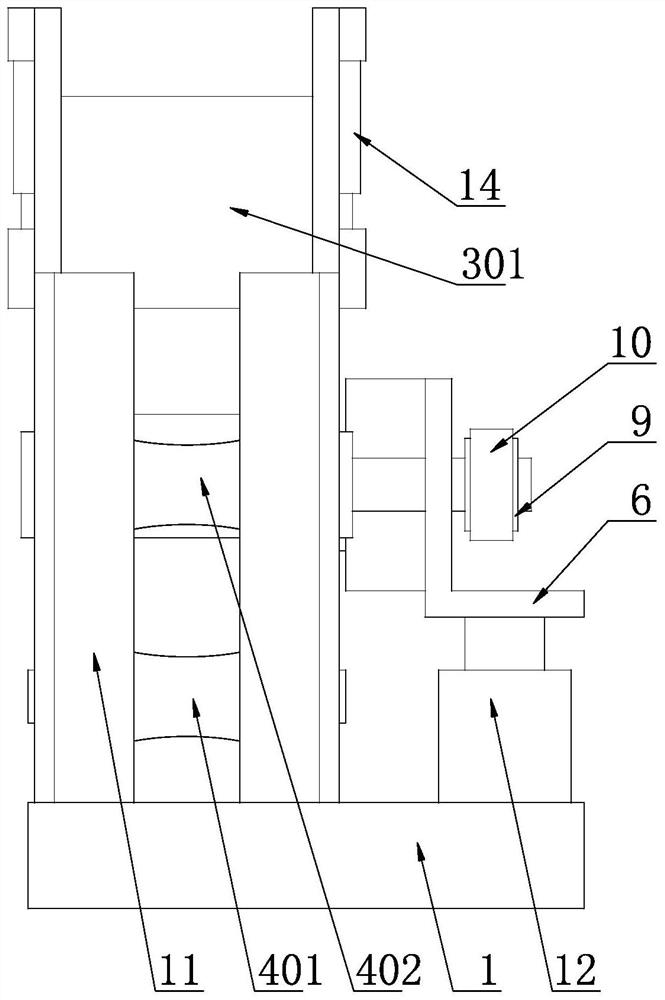

[0046] Such as Figure 1-13 As shown, a rubber hose marking system based on computer control, the rubber hose marking system includes a base 1, and the upper part of the base 1 is sequentially provided with a marking assembly 2 and a coating assembly 3 according to the conveying direction of the rubber hose. The rubber hose marking system also includes a positioning drive Component 4 and paint drying component 5, two sets of positioning drive components 4 are respectively located at the front end of the marking component 2 and the rear end of the coating component 3, and the pigment drying component 5 is located between the marking component 2 and the coating component 3;

[0047] The positioning drive assembly 4 includes a first idler roller 401 and a positioning roller 402. The first idler roller 401 is installed on the base 1 for lateral rotation, and the positioning roller 402 is located above the first idler roller 401. The positioning roller 402 is installed on the base 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com