Thin-wall concrete-filled steel tube column separated by tension and compression and its construction method

A technology of concrete columns and thin-walled steel pipes, which is applied in the direction of columns, pillars, pier columns, etc., can solve the problems that thin-walled steel pipes are prone to local buckling and the bearing capacity of thin-walled steel pipes is reduced, and achieve easy engineering design and simple division of labor , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is further described in conjunction with the following examples.

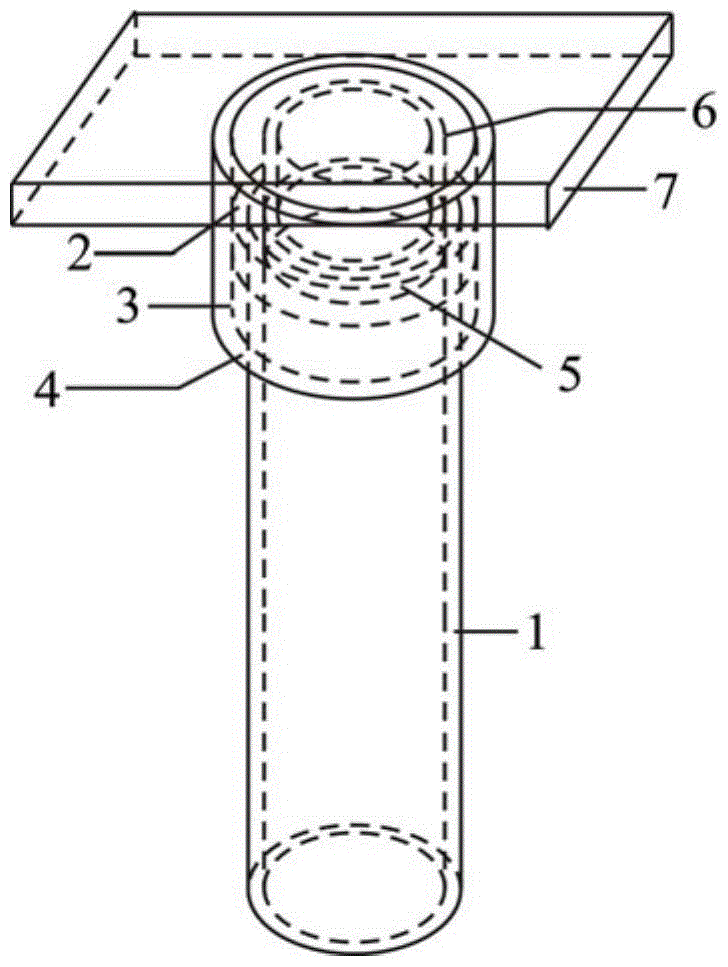

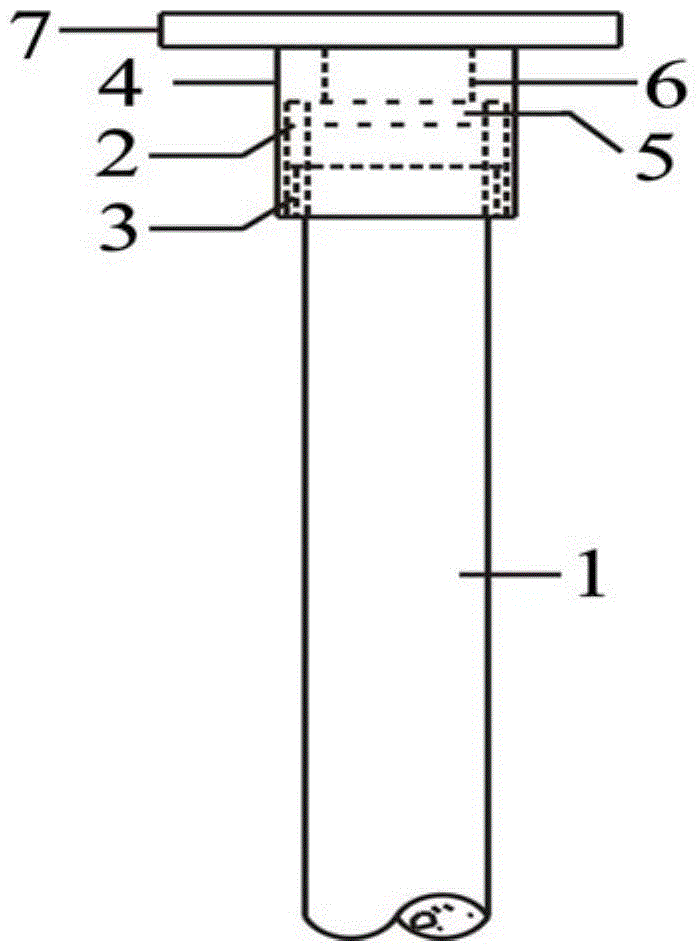

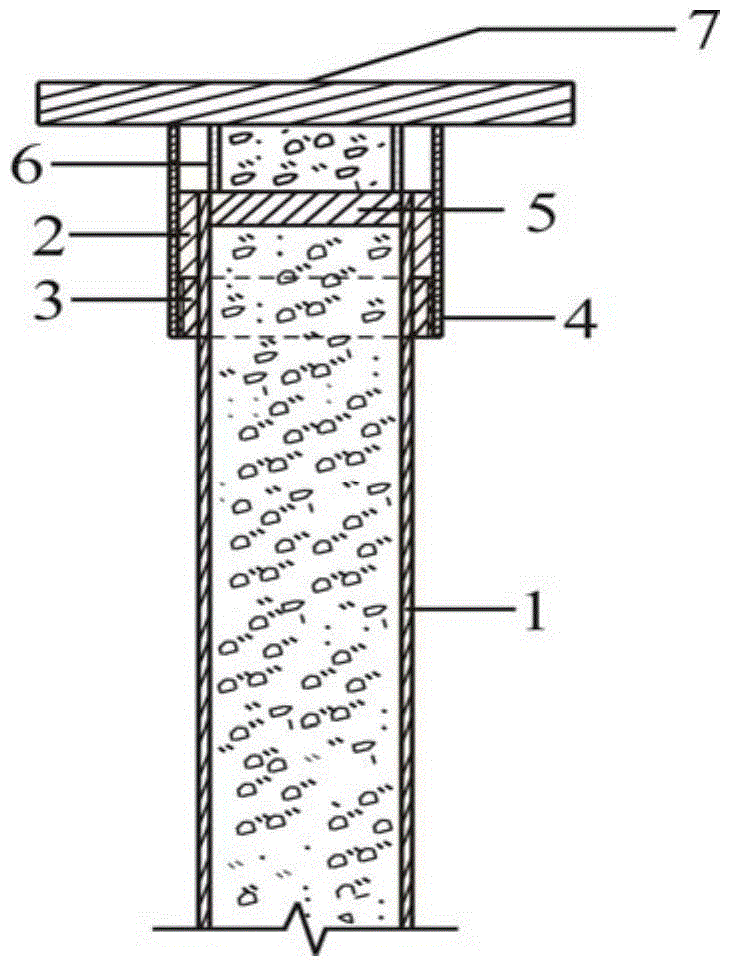

[0030] Such as Figure 1 to Figure 3 The thin-walled steel pipe concrete column includes a lower steel pipe 1 , a fixed ring plate 2 , a sliding ring plate 3 , a sleeved steel pipe 4 , a sealing steel plate 5 , an upper steel pipe 6 and a connecting steel plate 7 .

[0031] The lower steel pipe 1 is filled with concrete as a supporting core. The fixed ring plate 2 is welded on the top of the lower steel pipe 1, and its free end is flush with the top surface of the lower steel pipe 1. The sliding ring plate 3 is arranged immediately below the fixed ring plate 2, the sliding ring plate 3 can slide up and down along the length direction of the lower steel pipe 1, and the fixed ring plate 2 is used to prevent the sliding ring plate 3 from sliding to the top of the lower steel pipe 1; The steel plate 5 is supported on the concrete; the lower part of the upper steel pipe 6 is connected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com