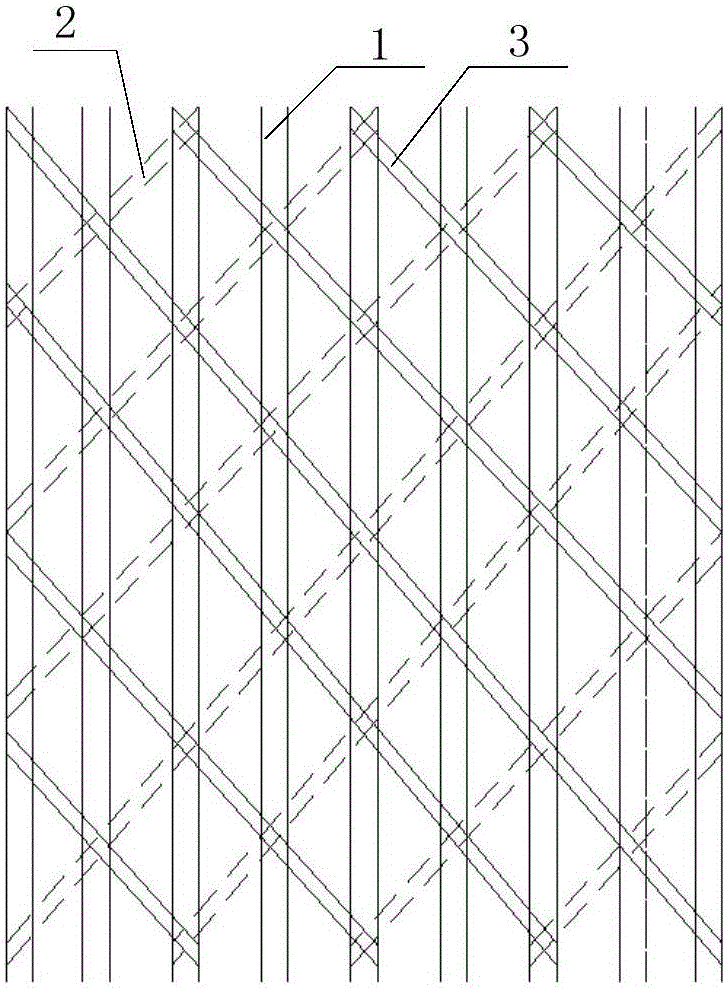

Wall based on raw bamboo framework

A skeleton and original bamboo technology, applied in walls, building components, buildings, etc., can solve the problems of affecting the service life of the wall, poor strength of the original bamboo wall, etc., to avoid flow and fall, avoid direct contact, and improve water resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

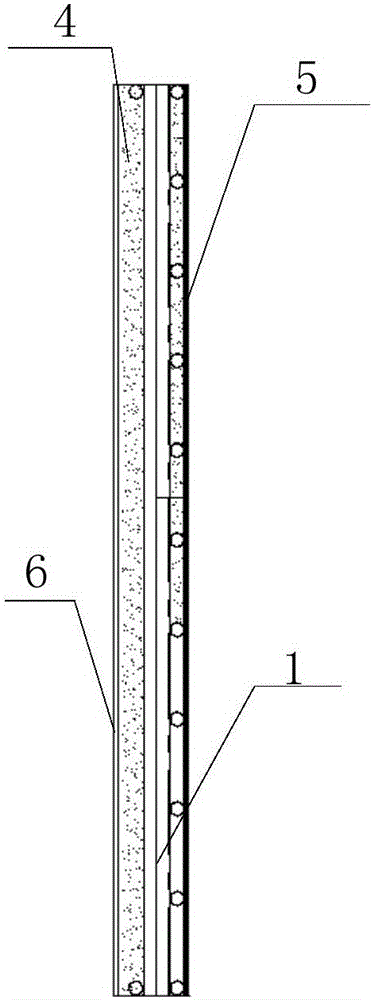

Embodiment 1

[0026] The gypsum-based thermal insulation material 4 is made of gypsum, expanded perlite, reinforcing fiber, cement, latex powder, citric acid, cellulose ether, water and water reducing agent, wherein the quality of expanded perlite is 18% of that of gypsum. %, the mass of reinforcing fiber is 0.25% of the mass of gypsum, the mass of cement is 35% of the mass of gypsum, the mass of latex powder is 0.1% of the mass of gypsum, the mass of citric acid is 0.125% of the mass of gypsum, the mass of cellulose ether 0.5% of the mass of gypsum, the mass of water is 75% of the mass of gypsum, and the mass of water reducer is 0.625% of the mass of gypsum.

[0027] The reinforcing fiber is composed of polyacrylonitrile fiber and wood fiber, wherein the mass of polyacrylonitrile fiber is 0.6% of the mass of gypsum, and the mass of wood fiber is 0.4% of the mass of gypsum.

[0028] The water reducer is FDN-A naphthalene series high-efficiency water reducer.

[0029] The particle size of t...

Embodiment 2

[0032] The gypsum-based thermal insulation material 4 is made of gypsum, expanded perlite, reinforcing fiber, cement, latex powder, citric acid, cellulose ether, water and water reducing agent, wherein the quality of expanded perlite is 9% of that of gypsum %, the mass of reinforcing fiber is 1% of the mass of gypsum, the mass of cement is 20% of the mass of gypsum, the mass of latex powder is 0.25% of the mass of gypsum, the mass of citric acid is 0.125% of the mass of gypsum, the mass of cellulose ether 0.5% of the mass of gypsum, the mass of water is 60% of the mass of gypsum, and the mass of water reducer is 0.625% of the mass of gypsum.

[0033] The reinforcing fiber is composed of polyacrylonitrile fiber and wood fiber, wherein the mass of polyacrylonitrile fiber is 0.15% of the mass of gypsum, and the mass of wood fiber is 0.1% of the mass of gypsum.

[0034] The water reducer is FDN-A naphthalene series high-efficiency water reducer.

[0035] The particle size of the ...

Embodiment 3

[0038] The gypsum-based thermal insulation material 4 is made of gypsum, expanded perlite, reinforcing fiber, cement, latex powder, citric acid, cellulose ether, water and water reducing agent, wherein the quality of expanded perlite is 12% of that of gypsum %, the mass of reinforcing fiber is 0.4% of the mass of gypsum, the mass of cement is 25% of the mass of gypsum, the mass of latex powder is 0.15% of the mass of gypsum, the mass of citric acid is 0.125% of the mass of gypsum, the mass of cellulose ether 0.5% of the mass of gypsum, the mass of water is 65% of the mass of gypsum, and the mass of water reducer is 0.625% of the mass of gypsum.

[0039] The reinforcing fiber is composed of polyacrylonitrile fiber and wood fiber, wherein the mass of polyacrylonitrile fiber is 0.25% of the mass of gypsum, and the mass of wood fiber is 0.2% of the mass of gypsum.

[0040] The water reducer is FDN-A naphthalene series high-efficiency water reducer.

[0041] The particle size of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com