Construction method for bottom sealing treatment of deep foundation pit springs

A construction method and technology for deep foundation pits, which are applied in basic structure engineering, construction, etc., can solve the problems of incomplete back cover and insignificant construction effect, and achieve the effects of high construction efficiency, shortened construction period, and simple and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

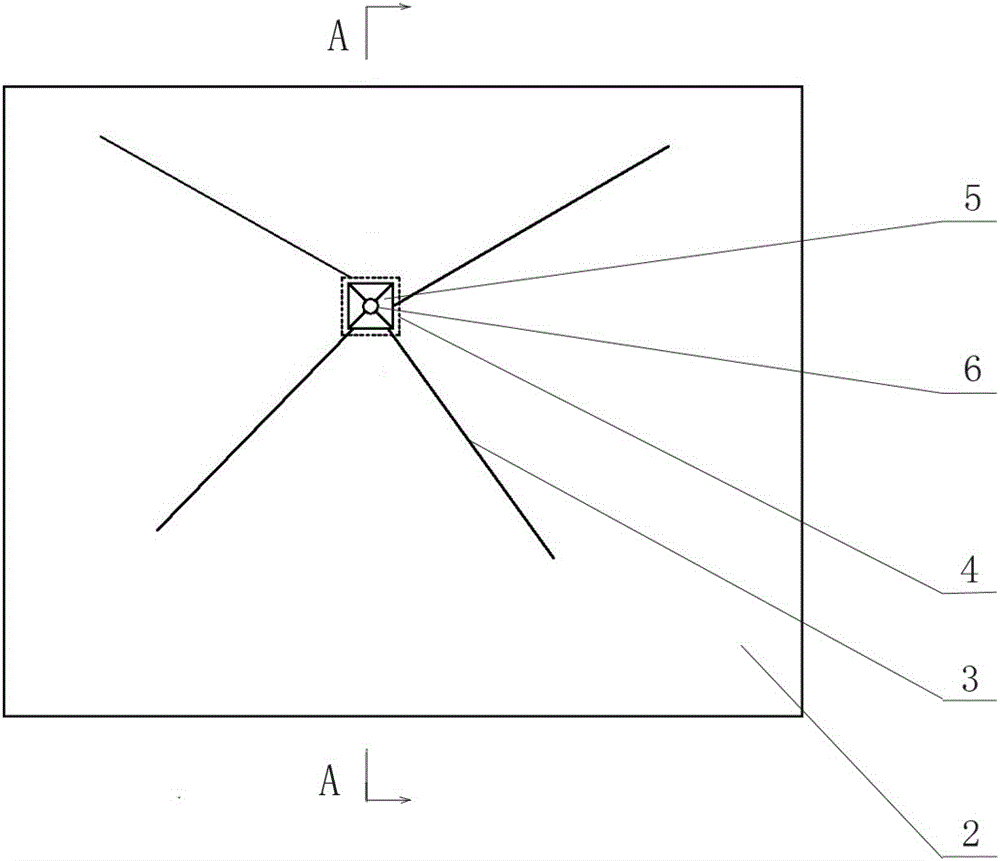

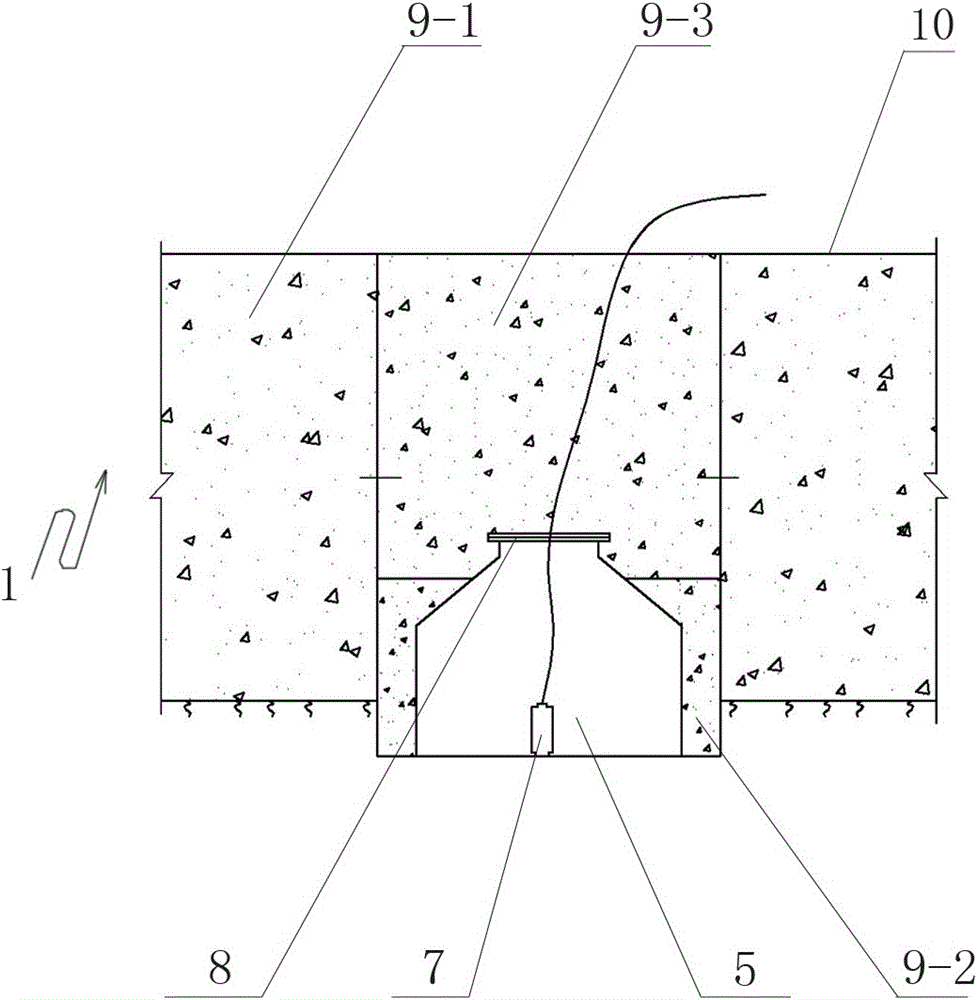

[0020] Such as figure 1 and figure 2 Shown, the concrete steps of the construction method that the present invention is used for deep foundation pit spring hole back sealing treatment are:

[0021] (1) According to the site construction situation, locate the springs that need to be blocked in the bottom of the deep foundation pit 2, and mark the positions of the central spring and the surrounding springs. Springs that need to be plugged except the central spring. A water diversion ditch 3 is set between each surrounding spring eye and the central spring eye. The distribution of the entire water diversion ditch 3 is radial in the center. The water diversion ditch 3 is filled with gravel to form a blind ditch, which can allow the water in the surrounding spring eyes to pass through the drainage. The process of ditch flowing into the sump 4 will not affect the pouring of concrete above it, so that the concrete pouring of the deep foundation pit and the drainage of the spring c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com