Bridge total external prestress concrete segment spliced light thin-walled box girder

A technology of external prestressing and concrete, which is applied in the direction of bridges, bridge materials, bridge construction, etc., can solve the problems of standard vacancy, low efficiency and high price, standardization and low level of industrialization, etc., to ensure safety and durability, and assemble bridges Fast speed, eliminating the effect of lax splicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific embodiments and accompanying drawings, but the following embodiments are only preferred embodiments of the present invention, not all . Based on the examples in the implementation manners, other examples obtained by those skilled in the art without making creative efforts all belong to the protection scope of the present invention.

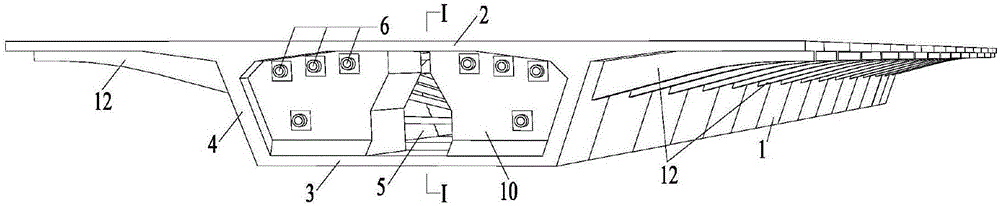

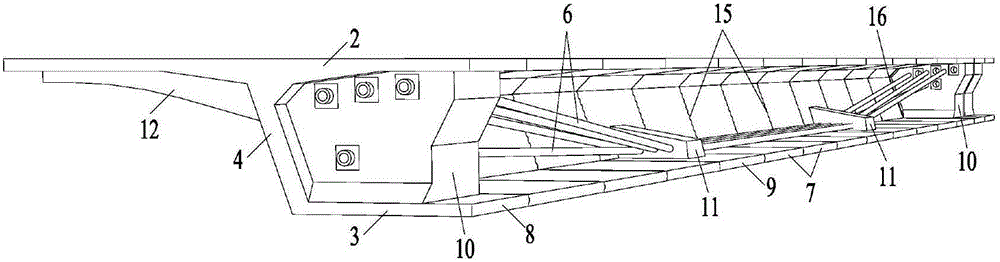

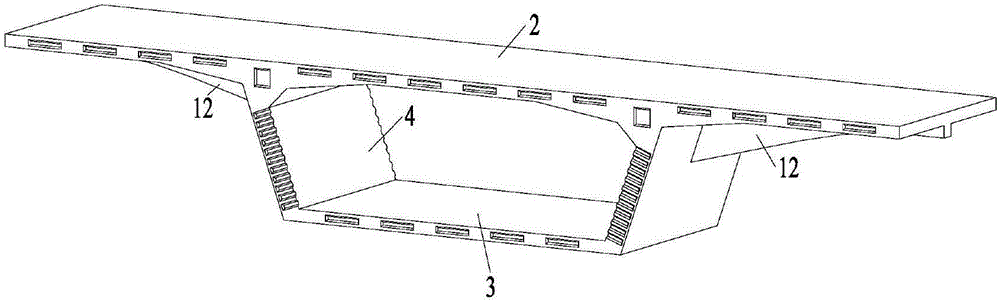

[0034] The light-weight thin-walled box girder assembled by the external prestressed concrete segments of the whole bridge is composed of several prefabricated segments 1, which are generally suitable for bridges with a span of 30m to 55m; the prefabricated segment 1 includes top plate 2, bottom plate 3 and web plate 4 , the top plate 2 and the bottom plate 3 are horizontally arranged in parallel, the web 4 is set between the top p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com