Sweater fabric loop variable-needle-pitch automatic alignment transfer type sewing machine

A variable needle and sewing machine technology, applied in knitting, textiles and papermaking, etc., can solve the problems of low efficiency, high cost, and unguaranteed quality, and achieve the effect of improving transfer efficiency, low cost, and reliable and accurate coil transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

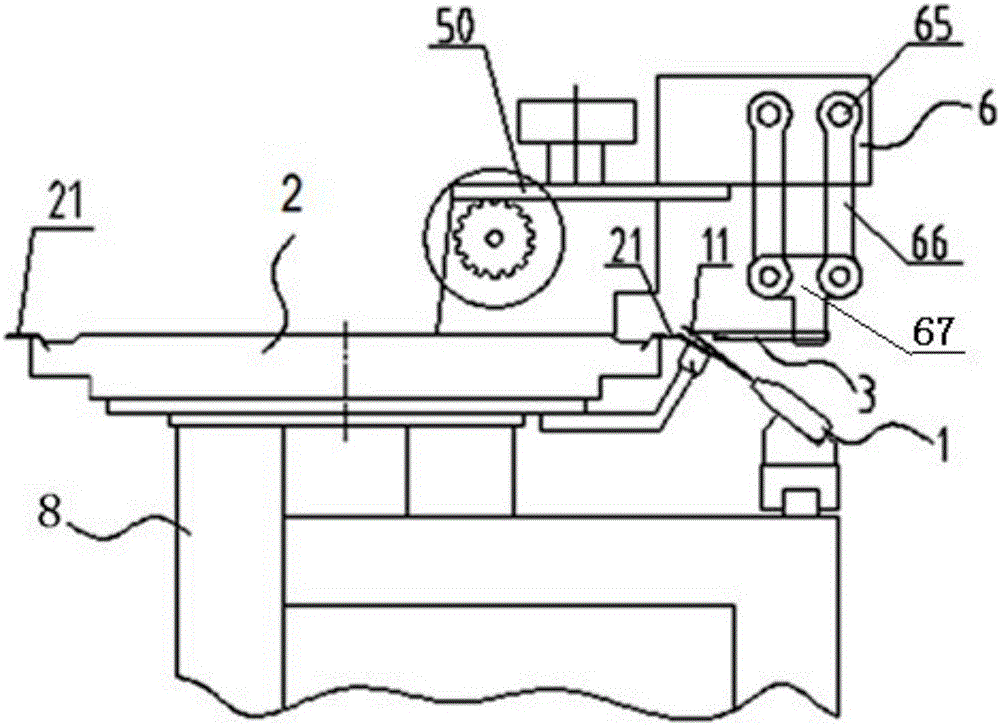

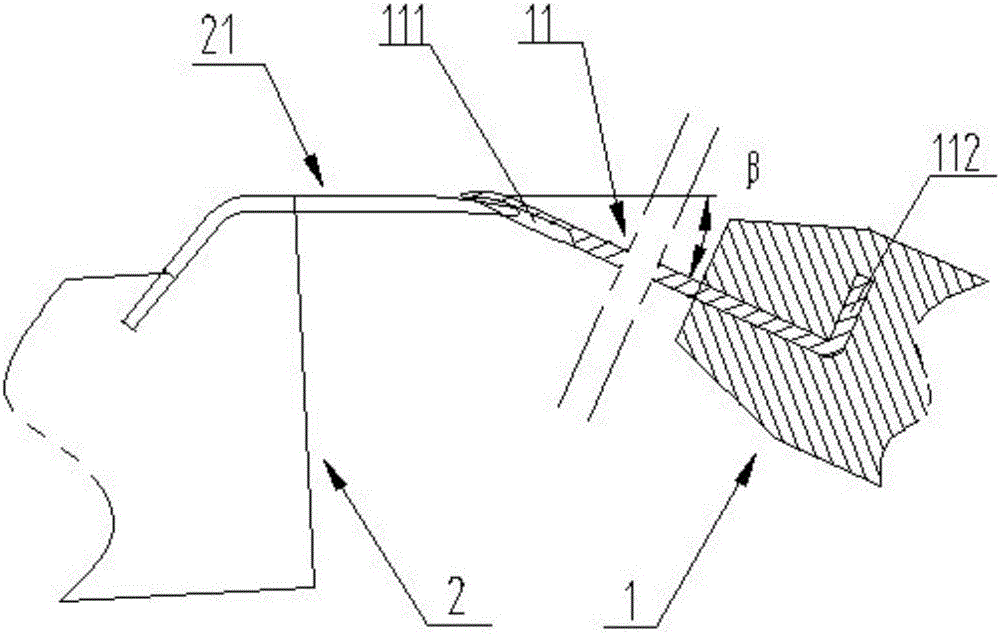

[0045] The invention relates to transferring the fabric on the transfer needle board to the rotating sewing machine, or to the laterally moving grooved needle board, that is, transferring the coils on the transfer needles of the transfer needle board to the sewing disk on the slotted needles of the machine, or transferred to the slotted needles of the slotted needle board. Therefore the present invention has included two kinds of variable needle distance automatic transfer sewing machines for the purpose.

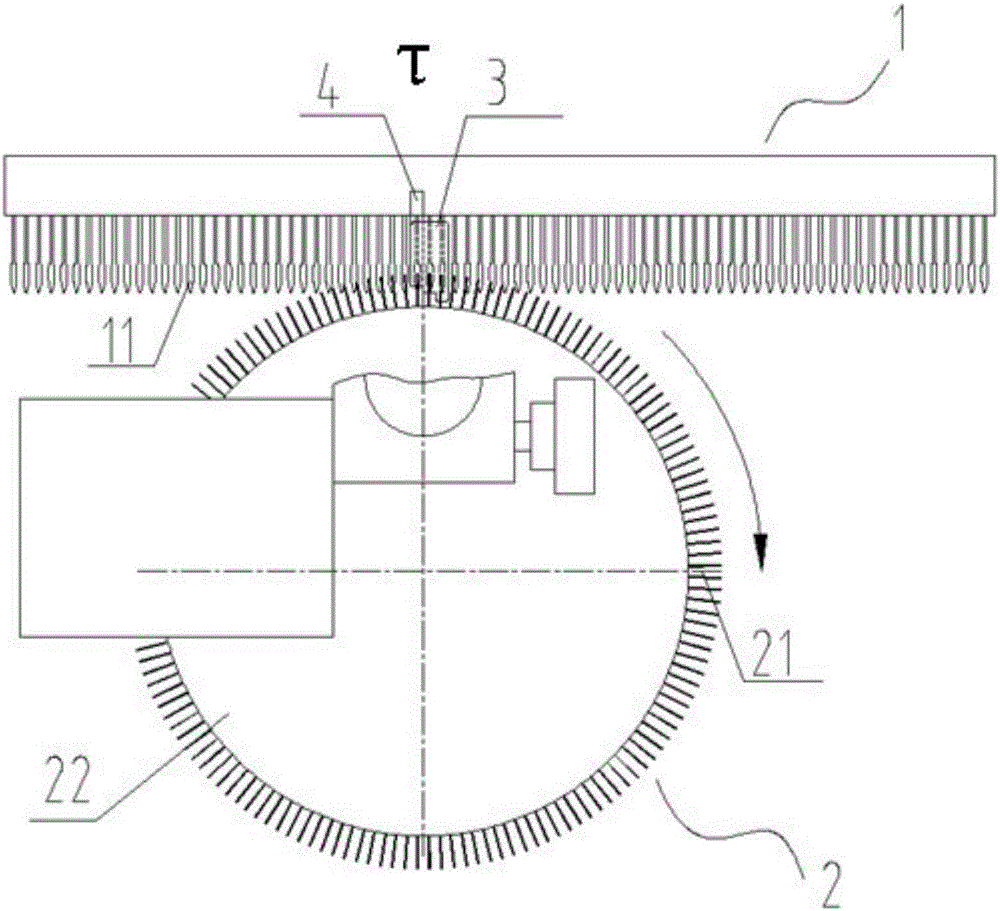

[0046] Such as figure 1 -3, is the first variable needle distance automatic eye-to-eye transfer sewing machine of the present invention, including a disc sewing machine 2, a transfer needle plate 1, a push plate 3 and a transfer needle groove needle joint unit 4. The sewing machine 2 has a rotating dial 22 and grooved needles 21 evenly distributed along the dial, and the transfer needle plate 1 is arranged at a tangential position on one side of the sewing machine dial 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com