Treatment method for improving mold steel surface frictional wear resistance

A technology of wear performance and treatment method, applied in the treatment field of improving the friction and wear resistance of die steel surface, can solve problems such as high brittleness, surface peeling, bonding failure, etc., to improve strength and toughness, solve easy wear and peeling, and eliminate seepage Effects of boron layer defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

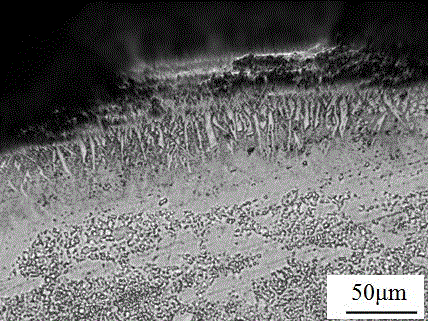

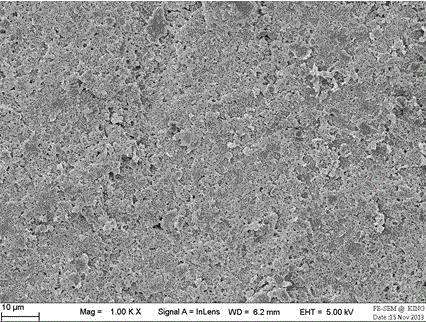

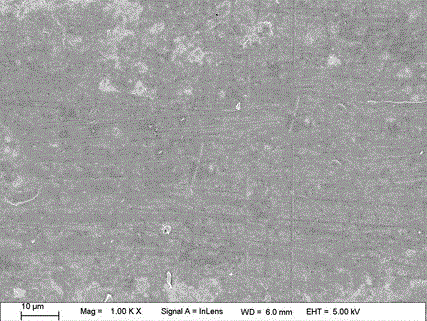

[0015] (1) The boronizing equipment is an externally heated crucible furnace. The salt bath composition includes boron donor, reducing agent and additives. The specific salt bath composition: 80%Na 2 B 4 o 7 +13%SiC+3.5%Na 2 CO 3 +3.5%KCl, the treatment process steps are: surface degreasing→rust removal→drying→boronizing→cleaning→annealing, when the temperature of the salt bath is heated to 950°C, immerse the substrate Cr12MoV mold steel in the salt bath and keep it warm for 6h After taking it out, the active boron atoms are in full contact with the surface of the substrate, and a diffusion reaction occurs to form a metallurgical bond.

[0016] (2) Borax should be dehydrated at 400-450°C before boronizing treatment, and other raw materials should be dried above 100°C. Borax without dehydration treatment should not be added to the furnace, so as to avoid salt bath aging and affect the quality of boronizing. Finally, the sample was boiled and washed with clean water for 10-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com