Disposable degradable table cloth and production technique thereof

A disposable tablecloth technology, applied in the field of tablecloths, can solve the problems of long degradation time, insufficient strength, environmental pollution, etc., and achieve the effects of excellent comprehensive performance, accelerated degradation speed, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

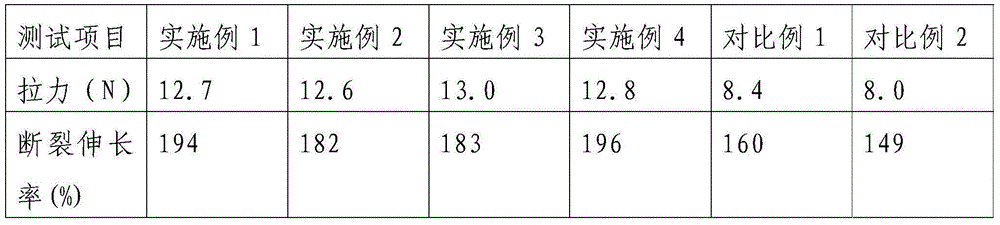

Examples

Embodiment 1

[0024] The formula of the disposable degradable tablecloth includes the following raw materials in parts by weight: 20 parts of polyethylene, 75 parts of ultrafine calcium carbonate, 2 parts of hollow glass microspheres, 0.1 part of photodegradant, 0.5 part of degradation induction period regulator, 0.1 parts of calcium tetrahydrophthalate.

[0025] Described photodegradant is iron stearate.

[0026] The degradation induction period regulator is an ultraviolet absorber UV531.

Embodiment 2

[0028] A recipe for a disposable degradable tablecloth, comprising the following raw materials in parts by weight: 25 parts of polyethylene, 50 parts of ultrafine calcium carbonate, 5 parts of hollow glass microspheres, 0.5 parts of a photodegradant, and 2 parts of a degradation induction period regulator Parts, 0.5 parts of calcium tetrahydrophthalate.

[0029] The particle size of the ultrafine calcium carbonate is more than or equal to 800 mesh.

[0030] Described photodegradant is calcium stearate.

[0031] The degradation induction period regulator is an ultraviolet absorber UV328.

Embodiment 3

[0033] The disposable degradable table cloth includes the following raw materials in parts by weight: 23 parts of polyethylene, 70 parts of ultrafine calcium carbonate, 5 parts of hollow glass microspheres, 0.3 parts of photodegradation agent, 1.5 parts of degradation induction period regulator, tetrahydro 0.2 parts of calcium phthalate.

[0034] The polyethylene is selected from low-density polyethylene, high-density polyethylene and linear low-density polyethylene to mix.

[0035] The particle size of the ultrafine calcium carbonate is more than or equal to 800 mesh.

[0036] The photodegradant is cerium stearate.

[0037] The degradation induction period regulator is a mixture of ultraviolet light absorber UV531 and nanometer titanium dioxide.

[0038] The production technology of above-mentioned disposable degradable tablecloth comprises the following steps:

[0039] 1) drying the superfine calcium carbonate to a moisture content≤0.1%;

[0040] 2) Add hollow glass micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile load | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com