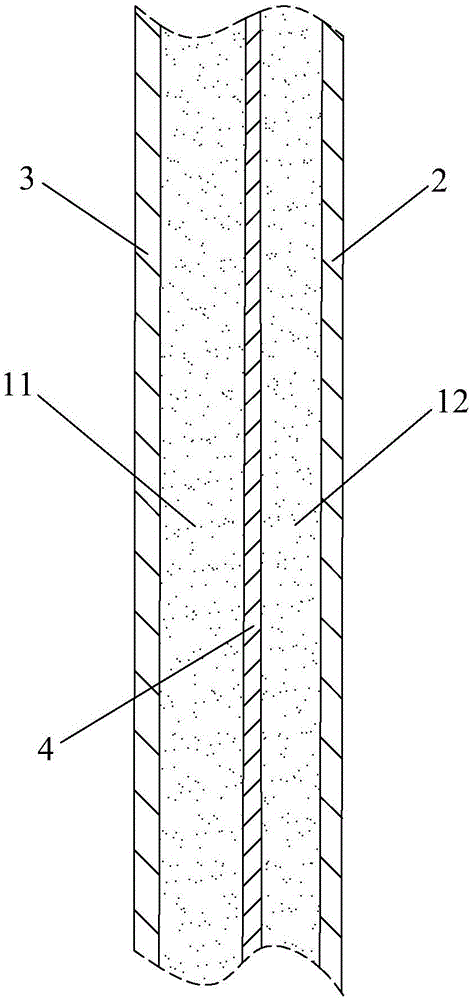

Conductive hydrogel, conductive hydrogel coil and their preparation methods

A conductive hydrogel, coiled material technology, applied in electrotherapy, conductive adhesives, electrodes, etc., can solve the problems of difficult unification, limited use of conductive hydrogels, etc., to achieve good stability, not easy to yellow, Very sticky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

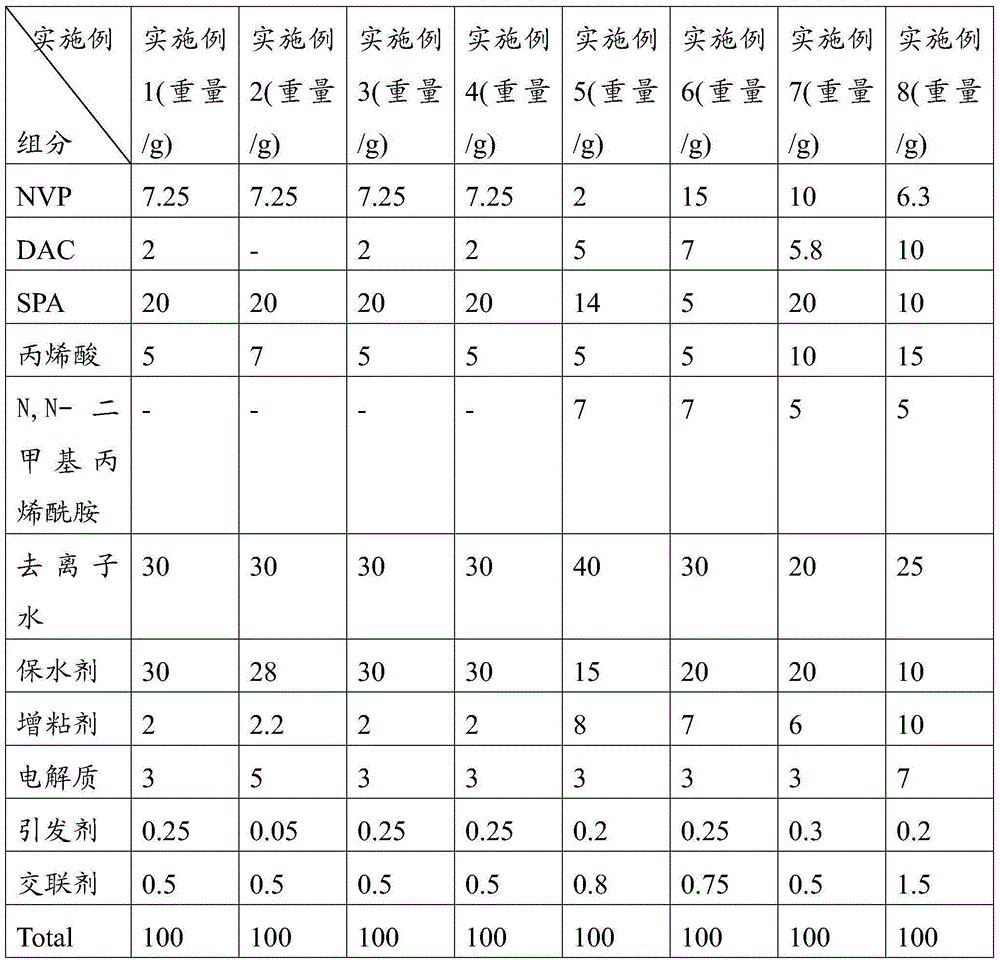

Embodiment 1

[0024] A kind of conductive hydrogel, its raw material includes N-vinylpyrrolidone (NVP) 7.25%, acryloyloxyethyl trimethylammonium chloride (DAC, Ciba) 2%, 3-sulfopropyl propane by weight percent Potassium Acrylate (SPA, Raschig, Germany) 20%, Acrylic Acid 5%, Glycerin 25%, Polypropylene Alcohol 6005%, Polypropylene Sodium (PAAS) 2%, Deionized Water 30%, Potassium Chloride (KCl) 3 %, photoinitiator 0.25% (specifically including Irgacure1840.1% and Darocur11730.15%) and crosslinking agent (SR-252) 0.5%.

Embodiment 2

[0026] A kind of conductive hydrogel, its raw material includes N-vinylpyrrolidone (NVP) 7.25%, 3-sulfopropyl propyl acrylate potassium salt (SPA, Raschig, Germany) 20%, acrylic acid 7%, glycerol by weight percentage 28%, polyacrylamide (PMA) 2.2%, deionized water 30%, a mixture of potassium chloride and sodium chloride 5%, photoinitiator 0.05% (specifically including Irgacure1840.01% and Darocur11730.04%) and cross Joint agent (SR-252) 0.5%.

Embodiment 3

[0028] A kind of conductive hydrogel, its raw material includes N-vinylpyrrolidone (NVP) 7.25%, acryloyloxyethyltrimethylammonium chloride (DAC, Ciba)) 2%, 3-sulfopropyl Potassium propyl acrylate (SPA, Raschig, Germany) 20%, acrylic acid 5%, gelatin 30%, polyvinylpyrrolidone (PVP) 2%, deionized water 30%, potassium chloride (KCl) 3%, photoinitiator 0.25% (specifically including Irgacure1840.10% and Darocur11730.15%) and cross-linking agent (SR-252) 0.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com