Purification method of creatine phosphate sodium

A technology of creatine phosphate sodium and a purification method, which is applied in chemical instruments and methods, compounds of group 5/15 elements of the periodic table, organic chemistry, etc., and can solve problems such as low production efficiency and low solubility of creatine phosphate calcium, Achieve high production efficiency and good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. For the experimental methods that do not specify specific conditions in the examples, usually follow the conventional conditions or the conditions suggested by the manufacturer.

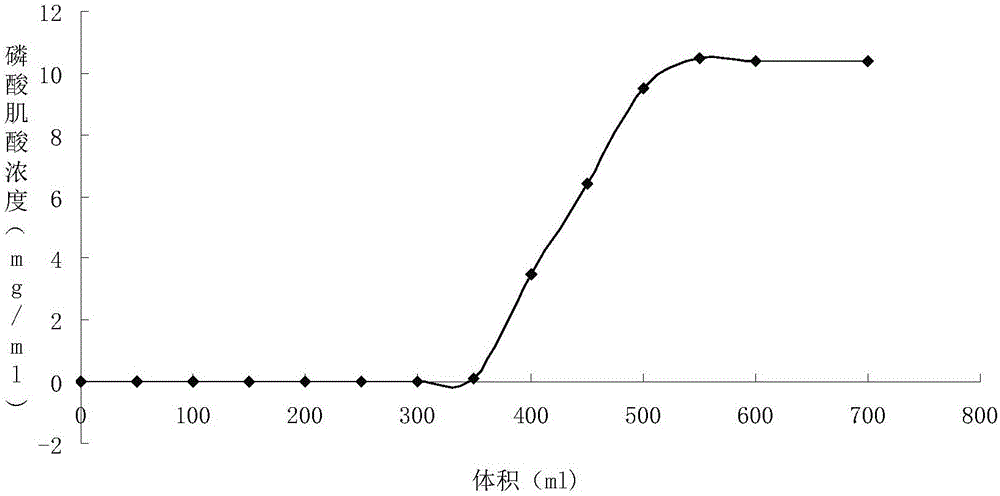

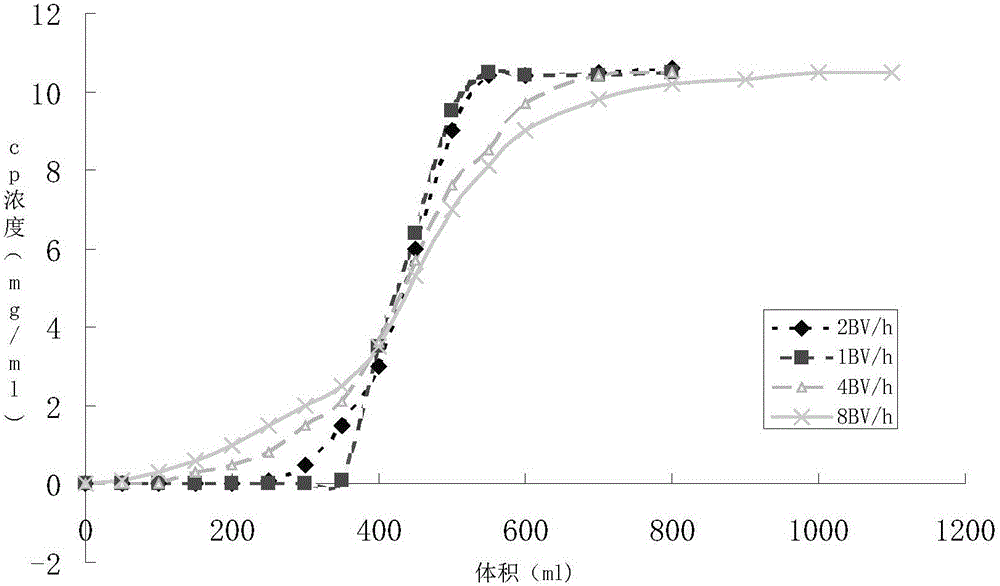

[0029] The purified creatine phosphate sodium sample in the present invention is that the molar ratio of creatine: ATP is in the range of 2:1 to 10:1, the reaction time is about 6h, the temperature is in the range of 5 to 40°C, and the pH is in the range of 9 to 40°C. 11. The concentration of magnesium ions should be within the range of 0.5 to 1.5 times the concentration of ATP. The product of the reaction under the catalysis of immobilized rabbit creatine kinase is hereinafter referred to as sodium creatine phosphate mother liquor. The mother liquor contains a large amount of creatine, creatine sodium phosphate, ADP, ATP, magnesium ions, and a small amount of AMP a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com