Slow-release oxygenator for preventing and treating etiological pathogenic bacteria of aquatic water and preparation method for slow-release oxygenator

A technology for cultivating water bodies and pathogenic bacteria, applied in the direction of light water/sewage treatment, sterilization/microdynamic water/sewage treatment, etc., to solve the problem of water quality deterioration, prevent and control pathogenic bacteria, and improve the effect of aquaculture production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

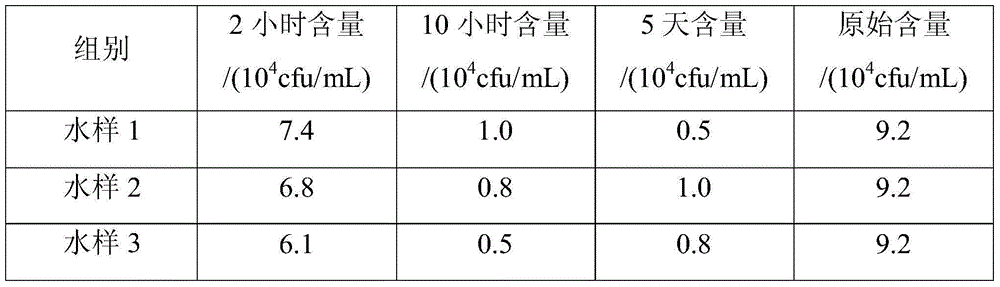

Examples

Embodiment 1

[0038] The slow-release oxygenator for preventing and treating pathogenic bacteria in aquaculture water of this embodiment is prepared from the following components by weight:

[0039] 17 parts of nano-titanium dioxide, 2.5 parts of rare earth metal salt, 0.8 parts of tourmaline anion powder, 28 parts of compound Chinese medicine admixture, 2.5 parts of polyvinyl alcohol, 82 parts of aeration mixture, 0.2 parts of sodium alginate, 1 part of sodium silicate, three parts 0.5 parts of boron fluoride, the compound Chinese medicine admixture is made from the following Chinese medicine raw materials: red snow willow, citrus veneer, oil residue fruit, small wax tree, thawberry root, yucca, Peruvian gum, and raw materials of Chinese medicine The effective substance content ratio of the compound is 2:1:1:3:0.5:2:3; the aeration mixture is composed of calcium peroxide and calcium hydroxide in a mass ratio of 5:2.

[0040] The preparation method is as follows:

[0041] (1) Weigh the nano-titan...

Embodiment 2

[0054] The slow-release oxygenator for preventing and treating pathogenic bacteria in aquaculture water of this embodiment is prepared from the following components by weight:

[0055] 19.5 parts of nano titanium dioxide, 2.8 parts of rare earth metal salt, 1 part of tourmaline anion powder, 36.5 parts of compound Chinese medicine admixture, 3.25 parts of carboxymethyl cellulose, 96 parts of oxygenation mixture, 0.35 parts of hydroxypropyl methylcellulose, hydroxyl 2 parts of ethylidene diphosphonic acid and 1.5 parts of dimethylaminoethyl methacrylate. The compound Chinese medicine admixture is made of the following Chinese medicine raw materials: red snow willow, oil orange veneer, oil residue fruit, small wax tree, partial Thalictrum root, yucca, Peruvian gum, the effective content ratio of each Chinese medicine raw material is 2:1:1:3:0.5:2:3; the aerobic mixture is composed of calcium peroxide and calcium hydroxide according to 5 : 2 mass ratio composition.

[0056] The prepa...

Embodiment 3

[0070] The slow-release oxygenator for preventing and treating pathogenic bacteria in aquaculture water of this embodiment is prepared from the following components by weight:

[0071] 22 parts of nano-titanium dioxide, 3.1 parts of rare earth metal salt, 1.2 parts of tourmaline anion powder, 45 parts of compound Chinese medicine admixture, 4 parts of hydroxypropyl methylcellulose, 110 parts of oxygenated mixture, 0.5 parts of polyvinyl alcohol, acetanilide 3 parts, 2.5 parts of polymer film-forming agent, the compound Chinese medicine admixture is made from the following Chinese medicine raw materials: red snow willow, oil orange veneer, oil residue fruit, small wax tree, thawberry root, yucca, Peru For the scented gum, the effective content ratio of the raw materials of traditional Chinese medicine is 2:1:1:3:0.5:2:3; the aerobic mixture is composed of calcium peroxide and calcium hydroxide in a mass ratio of 5:2.

[0072] The preparation method is as follows:

[0073] (1) Weigh t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com