A Compensable Equilibrium Winding Hysteresis Tensioner Used in Textile Machinery

A technology of textile machinery and tensioner, which is applied in the field of compensating and balanced winding hysteresis tensioner, can solve the problems of small winding tension adjustment range, scrapped tensioner, obvious nonlinear relationship, etc., so as to expand the tension adjustment range and extend the Tensioner life, the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with figure, the present invention will be further described by implementing individual examples, but not limited to the following examples.

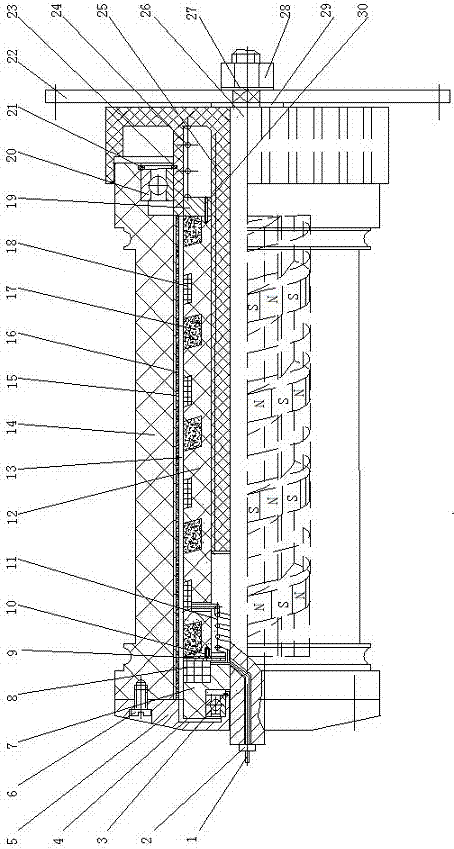

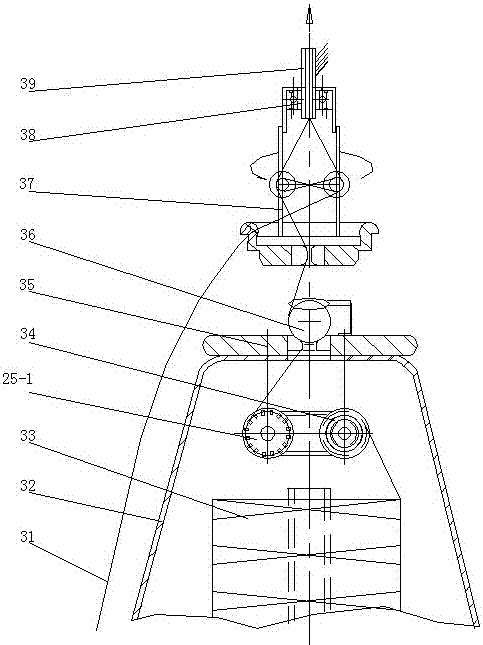

[0044] figure 1 It is an assembly diagram of the compensable and balanced winding hysteresis tensioner of the present invention, which can be divided into five parts to illustrate the implementation details.

[0045] (1) The left supporting part of the fixed mandrel 26: the inner hole of the bearing seat 7 with the compensation coil 8 is in interference static fit with the outer circle on the left side of the fixed mandrel 26 made of non-magnetic material, and the end hole of the bearing seat 7 is a bearing hole; The outer circle of the coil 8 has an insulating layer.

[0046] (2) The right supporting part of the fixed mandrel 26: the right side of the fixed mandrel 26 is sleeved with the tension adjustment disc 25, the right shoulder spacer washer 29, and the round fixed plate 22 is placed on the square sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com