a stockyard

A stockyard and material storage technology, which is applied in the field of storage and transportation facilities for bulk materials, can solve the problems of high pressure at the bottom of the warehouse, limited storage capacity of the warehouse body, and the width of the warehouse bottom cannot be too large, so as to improve the structural utilization rate and be affected. The effect of improving mechanical performance and increasing material storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

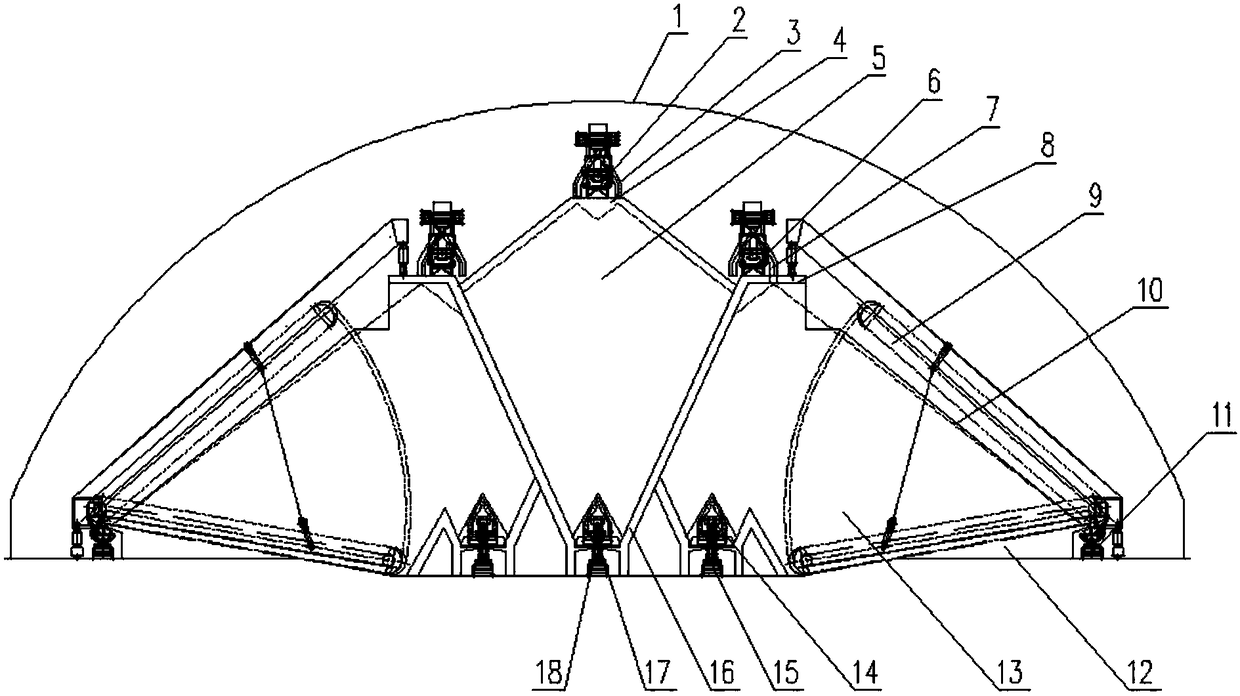

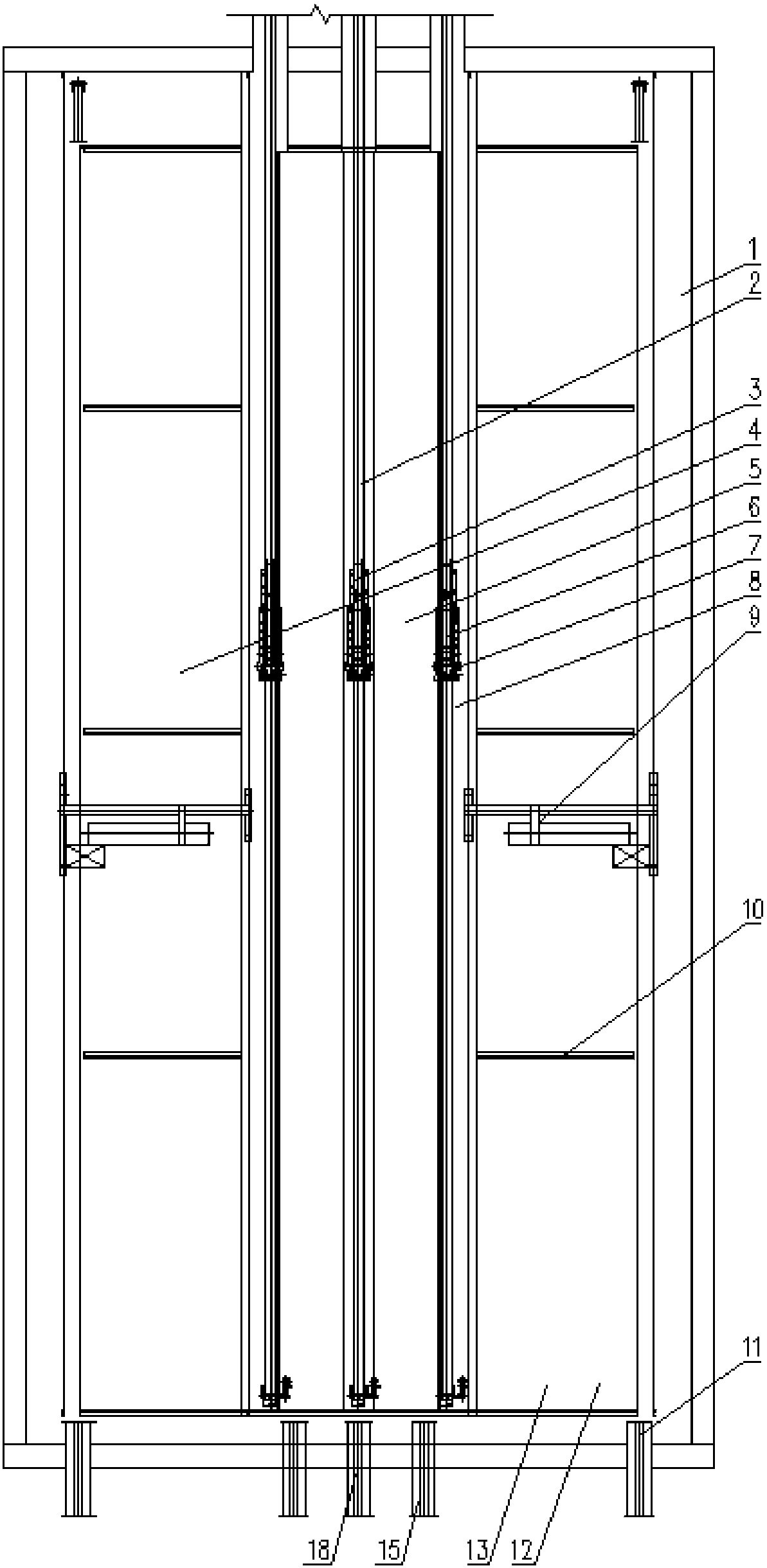

[0044] Such as figure 1 and figure 2 As shown, the present invention provides a kind of material yard, and this material yard is made up of closed material storage shed 1, input and stockpiling system, storage grid, storage bin 5, retrieving and output system, auxiliary system etc., the key is that storage The silo wall 16 is arranged obliquely, and is supported on the lateral retaining wall 10 of the storage compartment on its outer side, and the lateral retaining wall 10 of the storage compartment bears the vertical load of the material in the storage bin wall 16 and the storage bin 5. Storage silo wall 16 is provided with complete inclination among the examples.

[0045] Wherein the closed material storage shed 1 can be completely closed with wall skin, or adopt materials such as windshields, windshields, and windproof nets with a certain opening ratio to close. The closed material storage shed 1 closes the whole material yard, which can reduce the erosion of the materia...

Embodiment 2

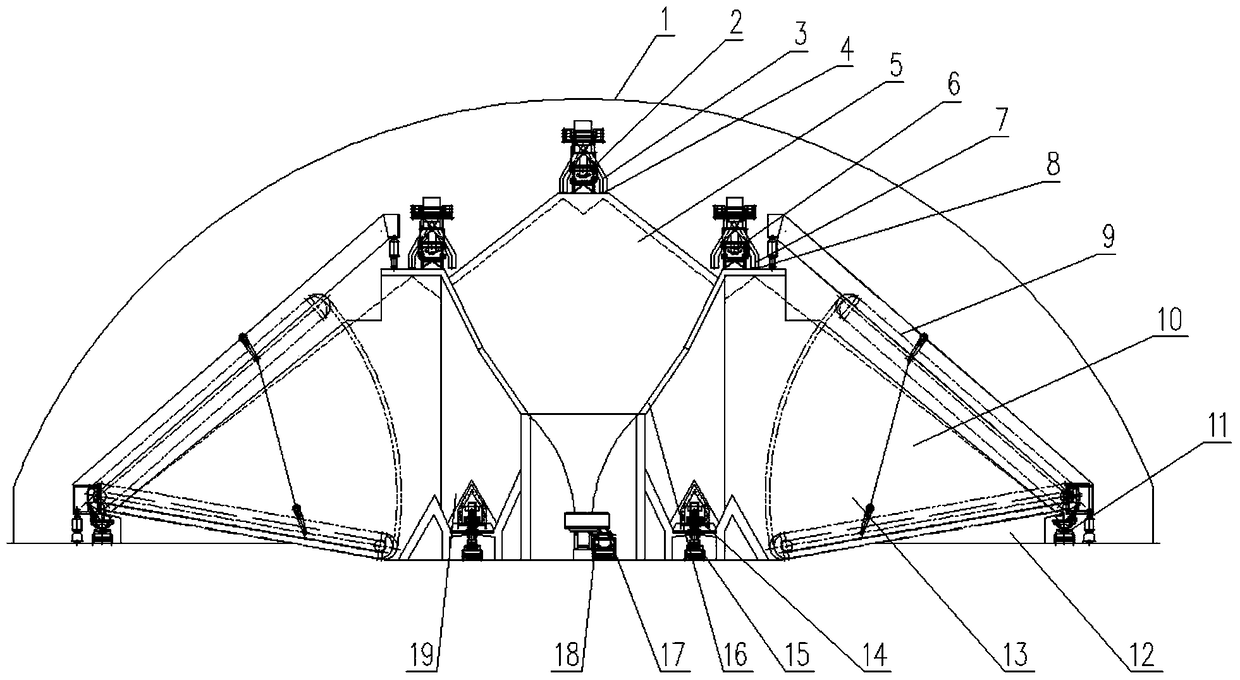

[0053] Such as image 3 and Figure 4 As shown, the difference from Example 1 is that the reclaiming equipment for the storage bin is a disc feeder, resulting in a slight difference in the lower part of the storage bin; the outer side of the storage bin wall 16 is provided with a web 19 to assist in supporting the storage warehouse and materials in the warehouse; in addition, the warehouse wall 16 of the storage warehouse is set to a broken line structure with a cross-section consisting of two oblique sections to make it easier for the material to slide down along the warehouse wall; the rest are the same as in Embodiment 1.

Embodiment 3

[0055] Such as Figure 5 As shown, the difference from Embodiment 1 is that the storage bin wall 16 is partially inclined, that is, the middle and lower part is inclined, the upper part is vertical, and the inclined part is supported on the horizontal retaining wall 10 of the storage compartment to form a partial support; And the top surface of the storage bin input conveyor running platform 4 is flush with the storage grid input conveyor running platform 8 .

[0056]The present invention makes full use of the supporting function of the structure of the horizontal retaining wall 10 of the storage grid, and designs the storage bin wall 16 as an oblique section, which is supported on the horizontal retaining wall 10 of the storage grid, and the horizontal retaining wall 10 of the storage grid bears the load of the storage bin The vertical load of the wall 16 and the material in the warehouse improves the force rationality of the horizontal retaining wall 10 of the storage compar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com