A tire press machine

A technology of pressing machine and tires, which is applied in the directions of tire installation, tire parts, transportation and packaging, etc., can solve the problems of inconvenient adjustment, unreasonable force on the pressing claw, and low pressing quality when replacing large and small tire products. It is suitable for promotion and application, scientific structural design, and the effect of reducing the use of the site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

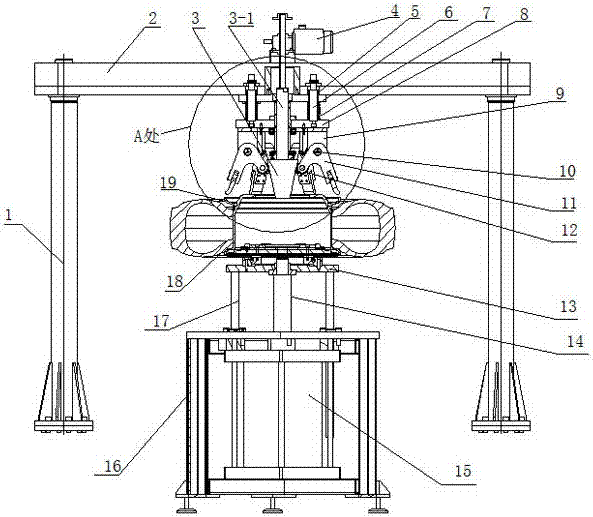

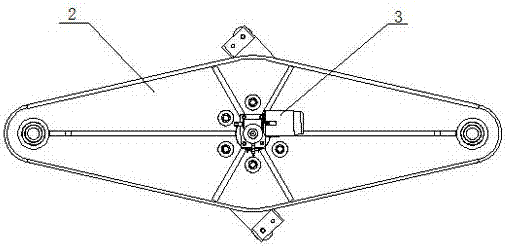

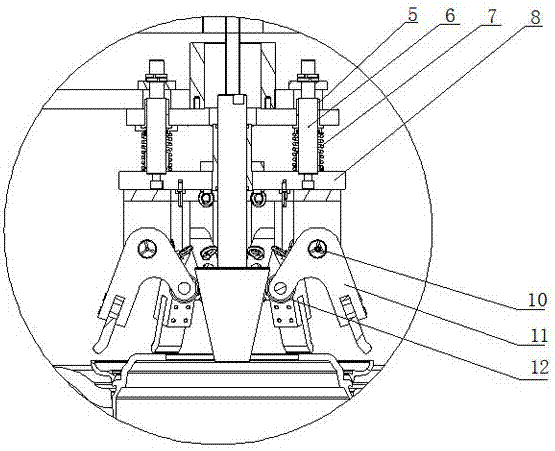

[0017] Such as figure 1 , figure 2 , image 3 As shown, the present invention is further described as follows: a tire press machine, including an upper frame 2, a lower frame 16, an electric control system (not expressed in the figure), the upper frame 2 is installed on the foundation through a column 1, and the lower frame The frame 12 is installed on the foundation, and the lower frame 16 is provided with a pneumatic jacking mechanism. The structure of the pneumatic jacking mechanism is that a lifting cylinder 15 is installed vertically upwards below the lower frame, and the positioning fixture 13 is located on the lower frame. On the top, the piston rod 14 of the lifting cylinder 15 is connected to the bottom of the positioning fixture 13, and the positioning fixture is vertically guided on the lower frame through a plurality of guide posts and guide sleeve assemblies 17;

[0018] The upper frame is equipped with a jaw press-fitting mechanism. The electric control system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com