Steel sleeve press-fitting device for plastic parts and press-fitting method of device

A technology for press-fitting devices and plastic parts, which is applied in metal processing, metal processing equipment, manufacturing tools, etc. It can solve problems such as the inability to ensure that the steel sleeve is pressed into the hole, the position deviation of the measurement hole, and the large amount of shrinkage deformation. , to achieve the effect of improving equipment utilization, high pass rate, and meeting quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

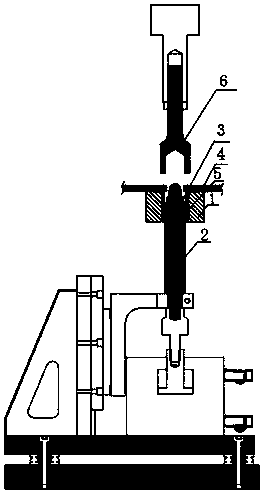

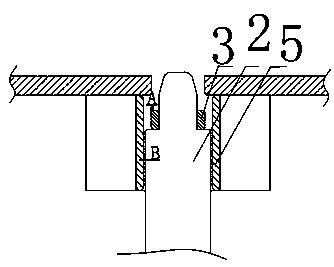

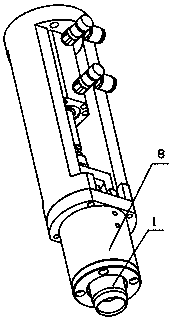

[0030] The invention discloses a steel sleeve press-fitting device for plastic parts and a press-fit method thereof, combining Figure 3-Figure 9 As shown, the press-fitting device includes a press-up mechanism and a lift-up mechanism that cooperates with the press-up mechanism and is arranged below the press-up mechanism. The upper pressing mechanism package is arranged on the centering rod 1 in the housing, and the head of the centering rod 1 is provided with a pressing groove, and the outer ring of the pressing groove is chamfered. In the present invention, the The chamfering adopts 1.5 mm, and the groove diameter of the press-fitting groove is equivalent to the aperture on the product to be press-fitted.

[0031] The upper end of the centering rod 1 is connected with the upper cylinder 2 through the floating joint 3, and the lower end of the centering rod 1 is respectively sleeved with a guide sleeve 7 and an upper platen seat 8. An O-ring 6 is arranged between the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com