Winding curing device for thin-walled skirts made of carbon fiber composites

A composite material and curing device technology, which is applied in the molding field of solid rocket motor housing accessory skirts, can solve the problems of increased maintenance costs and low dimensional accuracy of thin-walled skirts made of carbon fiber composite materials, and achieves improved dimensional accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

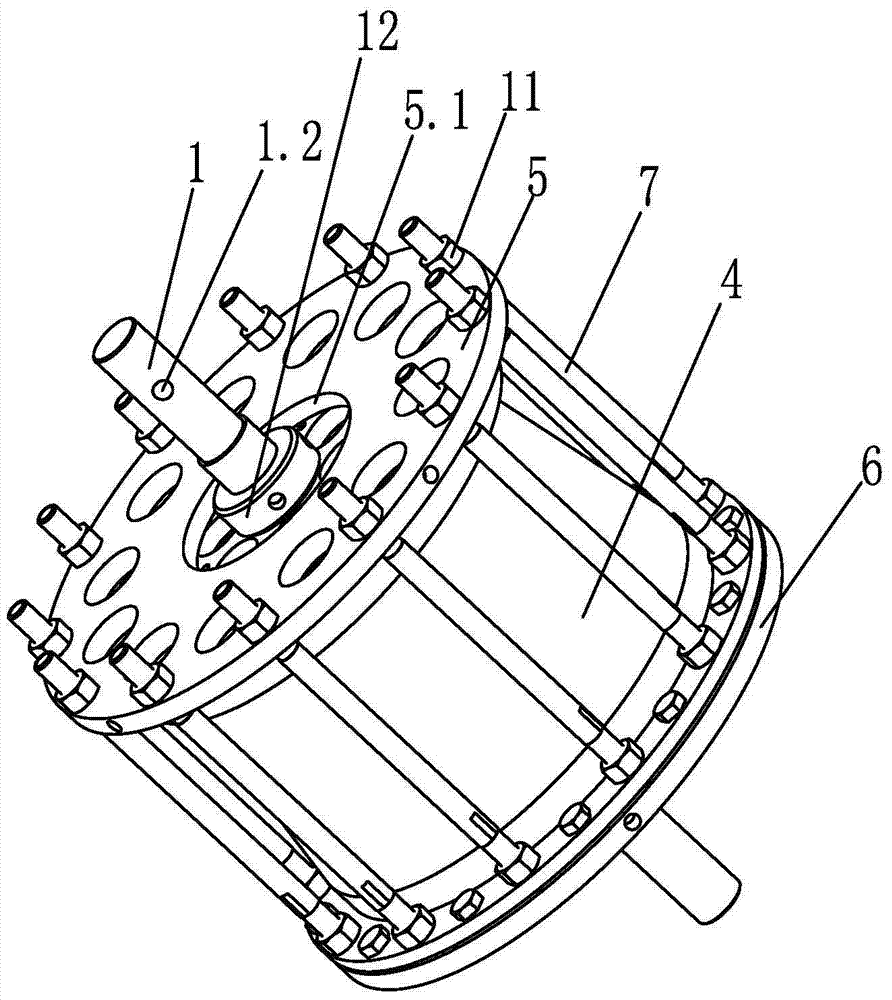

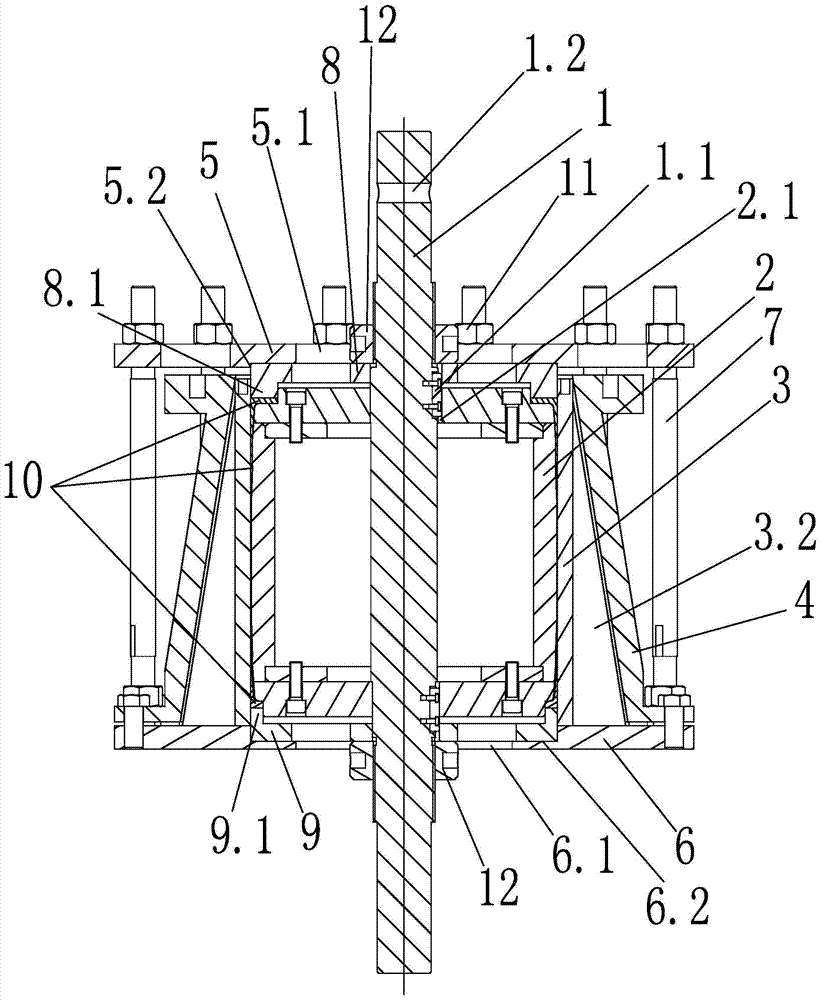

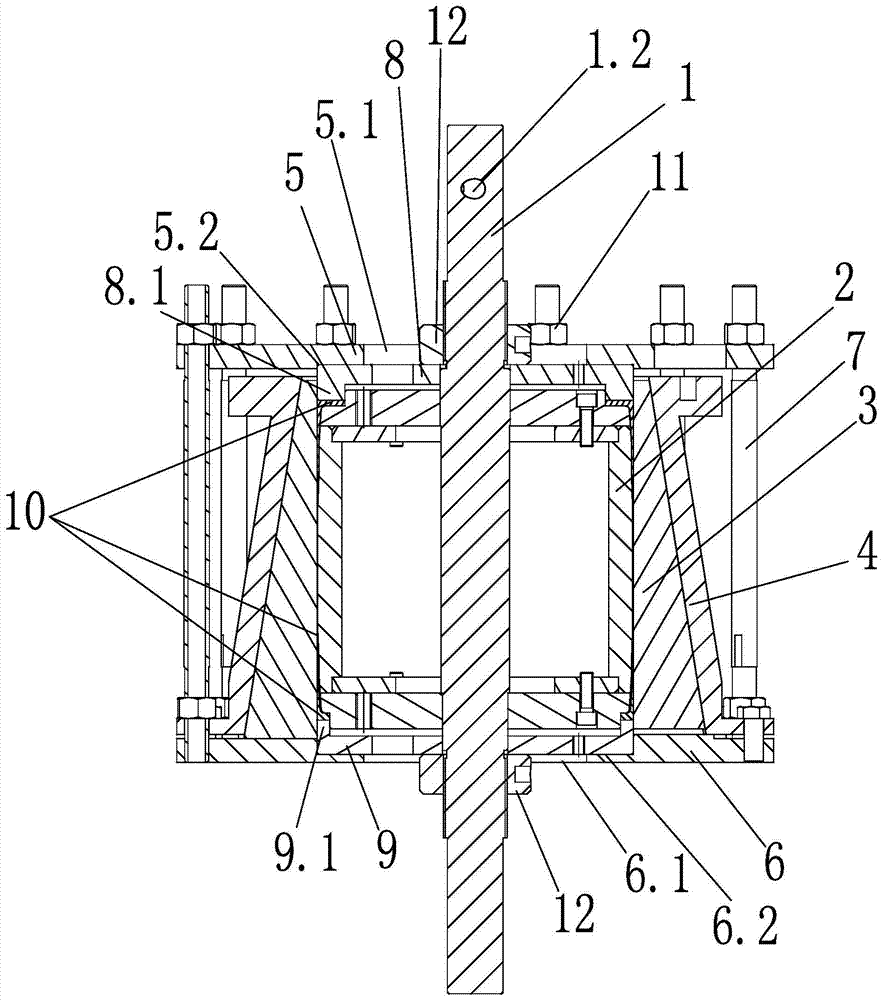

[0026] Such as Figure 1-8 The winding and curing device for thin-walled skirts made of carbon fiber composite materials includes a mandrel 1, a mandrel assembly 2 installed on the mandrel 1, an inner wedge-shaped cylinder 3, an outer wedge-shaped cylinder 4, an upper platen 5, Base 6, screw rod 7, upper adjusting plate 8 and lower adjusting plate 9, wherein, the first shaft hole 5.1 is provided on the upper pressing plate 5, and the bottom of the upper pressing plate 5 is provided with a radial limit on the top surface of the upper adjusting plate 8. The base 6 is provided with a second shaft hole 6.1 coaxial with the first shaft hole 5.1, and the base 6 is provided with a radial direction to the bottom surface of the lower adjustment plate 9 on the edge of the second shaft hole 6.1. Limiting positioning counterbore 6.2, the top surface of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com