Winding solidification device for carbon fiber composite thin-wall skirt part

A composite material and curing device technology is applied in the field of forming a skirt of a solid rocket motor casing attachment, which can solve the problems of increased maintenance cost and low dimensional accuracy of thin-walled skirt parts of carbon fiber composite materials, and achieves improved dimensional accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

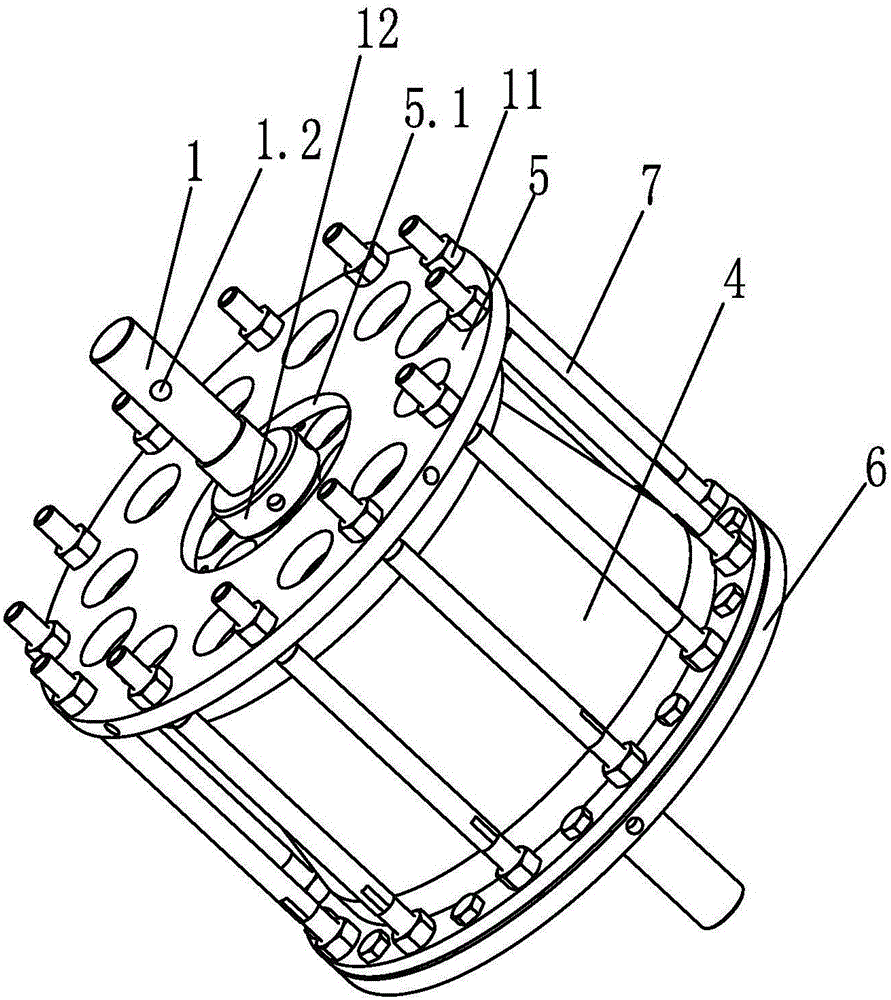

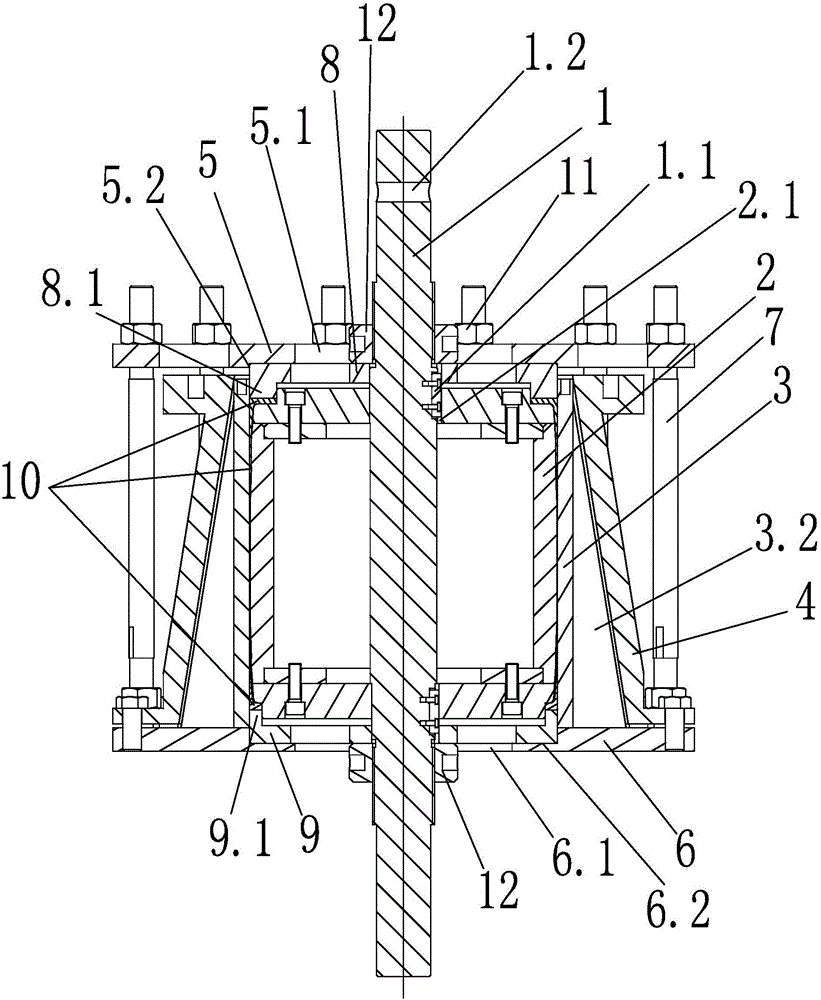

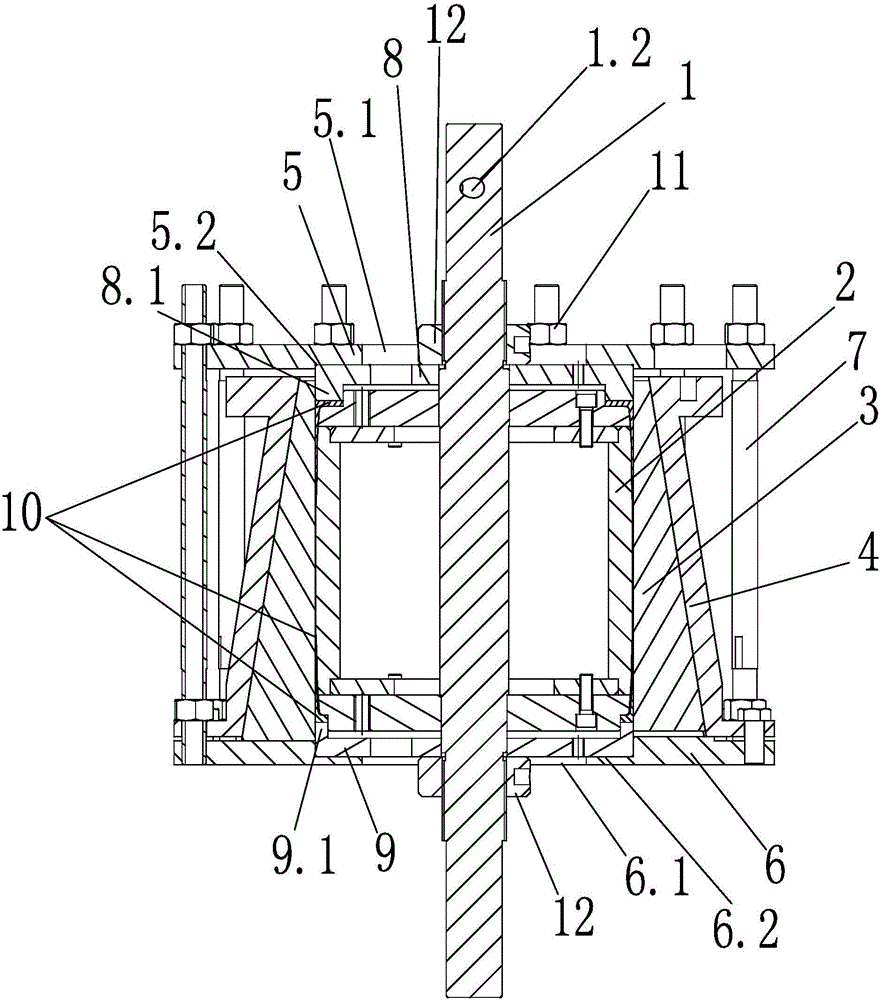

[0026] Such as Figure 1-8 The winding and curing device for thin-walled skirts made of carbon fiber composite materials includes a mandrel 1, a mandrel assembly 2 installed on the mandrel 1, an inner wedge-shaped cylinder 3, an outer wedge-shaped cylinder 4, an upper platen 5, Base 6, screw rod 7, upper adjusting plate 8 and lower adjusting plate 9, wherein, the first shaft hole 5.1 is provided on the upper pressing plate 5, and the bottom of the upper pressing plate 5 is provided with a radial limit on the top surface of the upper adjusting plate 8. The base 6 is provided with a second shaft hole 6.1 coaxial with the first shaft hole 5.1, and the base 6 is provided with a radial direction to the bottom surface of the lower adjustment plate 9 on the edge of the second shaft hole 6.1. Limiting positioning counterbore 6.2, the top surface of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com