Steel pipe welding device

A welding device and steel pipe technology, applied in welding equipment, tubular objects, applications, etc., can solve the problems of excessive welding quantity, poor welding accuracy, uneven penetration, etc., and achieve the effects of easy control, good welding effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0021] The invention will be described in detail below with reference to the accompanying drawings and examples.

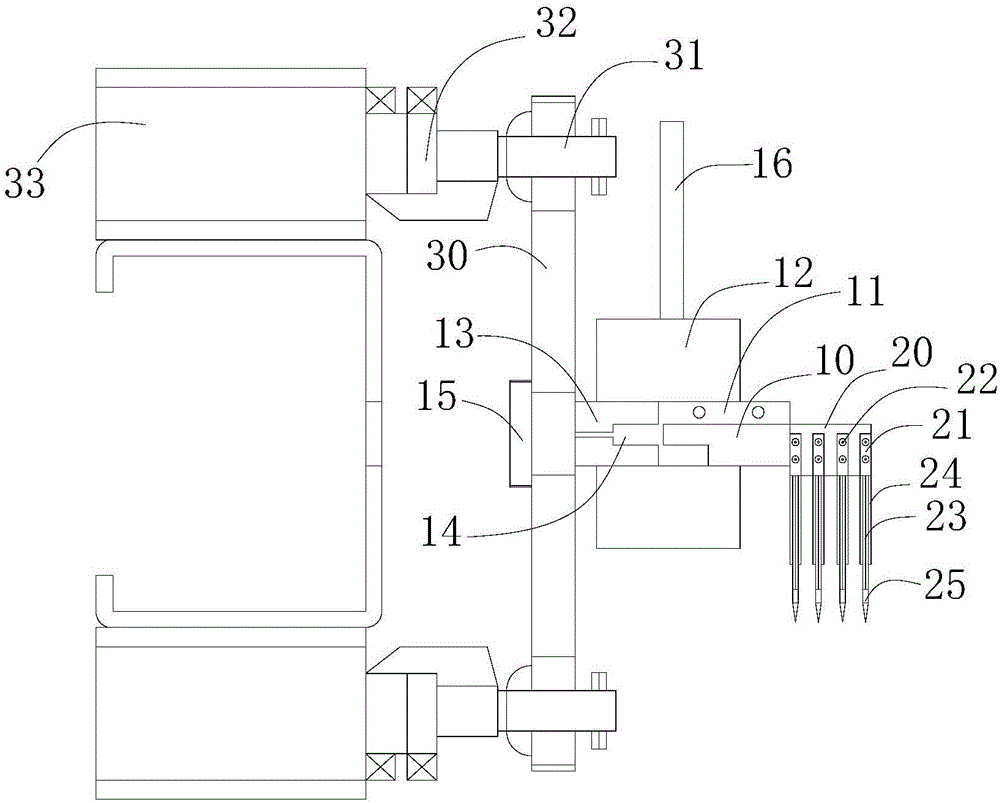

[0022] A steel pipe welding device, including a welding part and an adjustment part, the welding part includes a receiving seat 12, a fixing seat 11, a connecting part 10, a welding machine base 20, a fixing bracket 23, a heating plate 24 and a welding head 25; the adjustment The part includes a fitting 32, a rotating mechanical arm 31 and a propulsion tube 30;

[0023] The fixed seat 11 is a cuboid metal seat, the fixed seat 11 is vertically fixed on the receiving seat 12, the fixed seat 11 is fixedly connected to the center of the propulsion tube 30 through the clamping seat 15, and the receiving seat 12 is fixed on the machine tool On the main body, at least one connecting pipe 16 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com