Double-face chamfering continuous machining system for gear sleeve of vehicle synchronizer

A processing system and synchronizer technology, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems that machine tools cannot realize on-line processing, waste parts flow into the next process, and industrial production cannot be realized. Flexibility, scientific structure, and the effect of improving machining accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

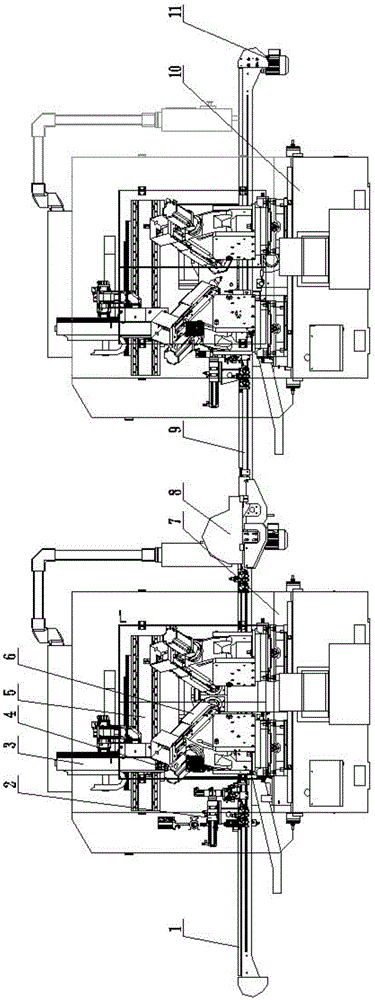

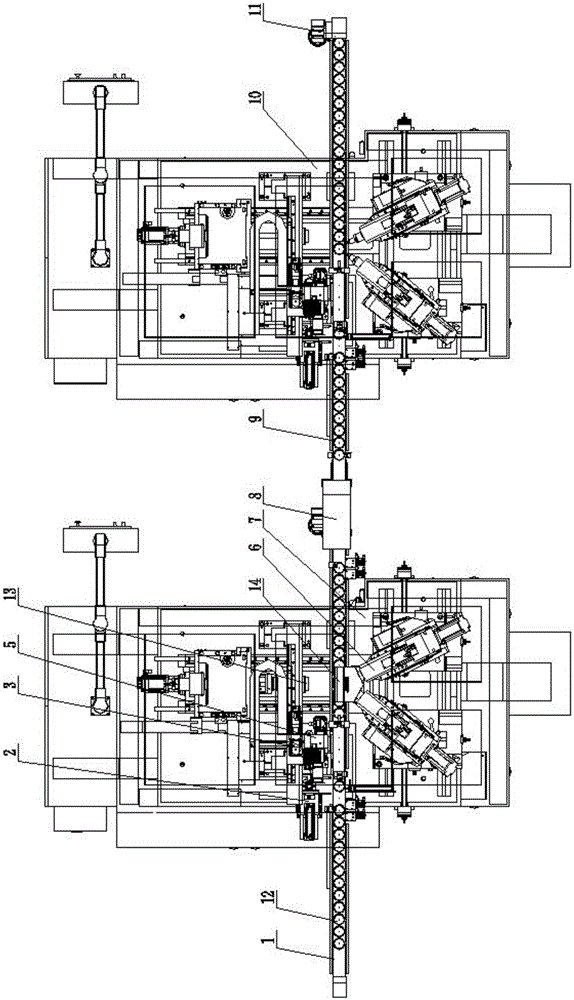

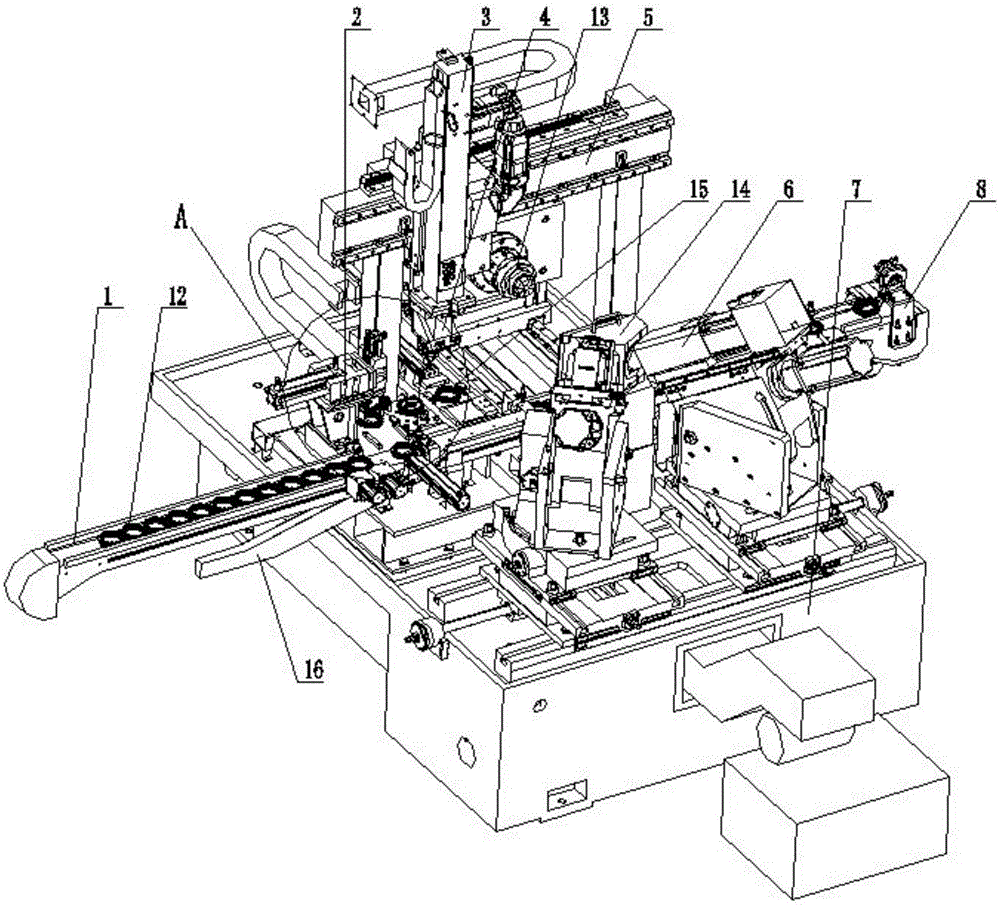

[0041] A continuous processing system for double-sided chamfering of automobile synchronizer gear sleeves, see figure 1 , 2, 3, 4 are made of two identical double-knife chamfering machines 7,10 and a linear feeding mechanism 1,9 that traverses the two chamfering machining stations. Two identical double-knife chamfering machines are arranged side by side in a row, and each chamfering machine includes a cutter 6 for chamfering, a workpiece driving head 13 and a gear alignment mechanism 2, and the cutters are two in parallel, two The center line where the tool is located is set facing the workpiece driving head; the gear alignment mechanism is set at the front process part of the workpiece driving head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com