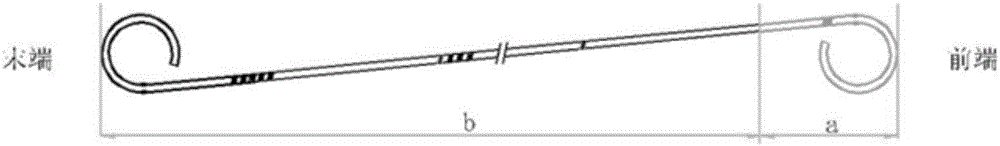

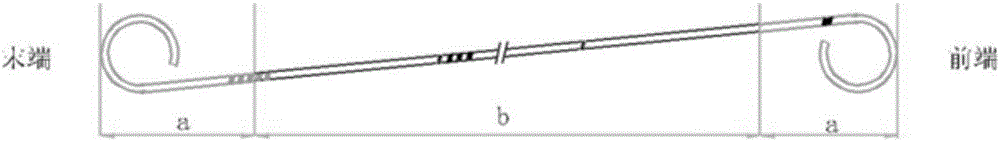

Double-J tube and preparation method thereof

A catheter and drainage tube technology, applied in the field of double-J tubes and their preparation, can solve the problems affecting the quality of life of patients, bleeding, affecting the effect of surgical treatment, etc., and achieve the effect of improving the effect of surgical treatment, improving the quality of life, and reducing complications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of manufacturing method steps of novel double J tube:

[0035] 1. First use polyurethane to make catheters with the same inner and outer diameters with hardnesses of 50A and 70A respectively. Both catheters have an outer diameter of 4F, an inner diameter of 0.8mm, and a length of 100cm;

[0036] 2. Cut catheters with different hardness into catheters of a certain length according to needs, which can be 5cm, 10cm, 15cm, 20cm, 25cm, 30cm. Note that the cutting end should be flat and free of burrs, otherwise it will affect the surface of the catheter during welding. smooth;

[0037] 3. Select 50A catheter 15cm and 70A catheter 30cm, select the appropriate size of the metal core to insert into the catheter with different hardness. Choose a 5cm metal outer sleeve to be inserted into catheters of different hardness with metal inner cores. The metal inner core and metal sleeve are made of special materials and processes, such as plasma polishing technology, and it mus...

Embodiment 2

[0041] 1. First use polyurethane to make catheters with the same inner and outer diameters with hardnesses of 65A and 75A respectively. Both catheters have an outer diameter of 5F, an inner diameter of 0.92mm, and a length of 100cm;

[0042] 2. Cut catheters with different hardness into catheters of a certain length according to needs, which can be 5cm, 10cm, 15cm, 20cm, 25cm, 30cm. Note that the cutting end should be flat and free of burrs, otherwise it will affect the surface of the catheter during welding. smooth;

[0043] 3. Select a 15cm2 section of the 65A catheter and a 15cm section of the 75A catheter, and select a 50cm metal core to insert into the catheter with different hardness. Select the appropriate metal outer sleeve to fit into catheters of different hardness with metal inner cores. The outer diameter and inner diameter of the metal inner core and the metal casing should be smooth without any burrs and unevenness.

[0044] 4. Put the two sections of catheters...

Embodiment 3

[0047] 1. First use polyurethane to make catheters with the same inner and outer diameters with hardnesses of 65A and 90A respectively. Both catheters have an outer diameter of 6F, an inner diameter of 1.3mm, and a length of 100cm;

[0048] 2. Cut catheters with different hardness into catheters of a certain length according to needs, which can be 5cm, 10cm, 15cm, 20cm, 25cm, 30cm. Note that the cutting end should be flat and free of burrs, otherwise it will affect the surface of the catheter during welding. smooth;

[0049] 3. Choose 65A catheter 15cm and 90A catheter 20cm, choose the appropriate size of the metal core to insert into the catheter with different hardness. Choose a 5cm metal outer sleeve to be inserted into catheters of different hardness with metal inner cores. The metal inner core and metal sleeve are made of special materials and processes, such as plasma polishing technology, and it must be ensured that the outer wall or the inner and outer walls are smoot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com