Locking and pressurizing bone setting device

A bone plate and compression hole technology, applied in the direction of fixator, internal fixator, internal bone synthesis, etc., can solve the problems of too many screws, large damage to the patient's soft tissue and bone tissue, and increase the patient's bone nonunion. Small volume, recovery of limb function, and reliable internal fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

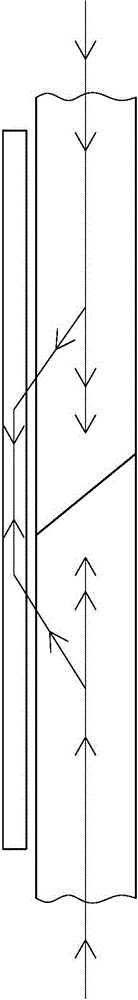

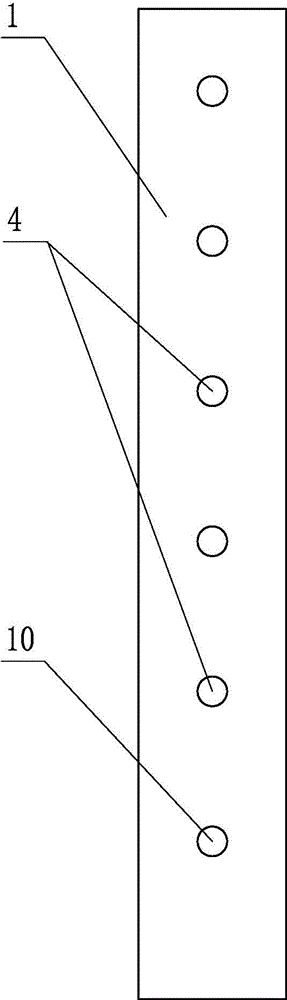

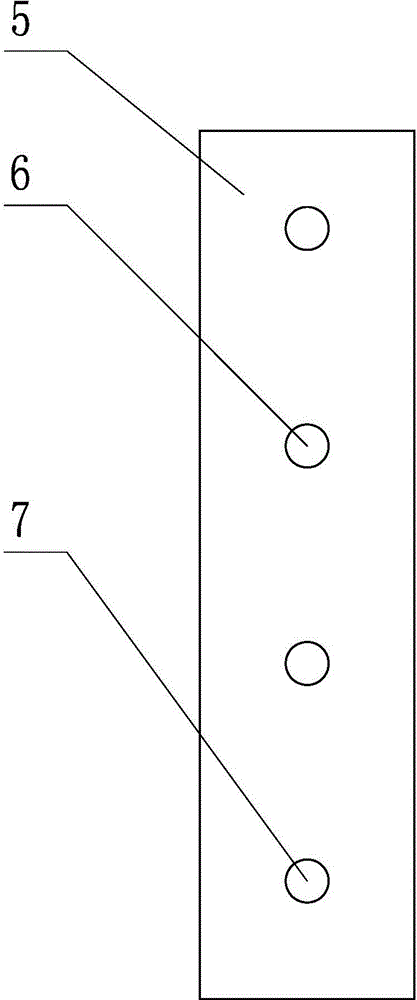

[0029] Depend on figure 2 , image 3 , Figure 4 , Figure 5 It can be known that a locking and compression bone setting device includes a main locking and compression bone setting plate 1, a locking screw 2, and a sleeve 9. The main locking and compression bone setting plate 1 is provided with a main locking screw hole 4 corresponding to the locking screw 2, It also includes an auxiliary locking bone plate 5 and two positioning rods 8 corresponding to the sleeve 9. The auxiliary locking bone plate 5 is applied simultaneously with the main locking compression bone plate 1, and at least one of the auxiliary locking bone plates 5 is provided. Secondary locking screw hole 7 and one secondary screw hole 6, the position and size of the secondary locking screw hole 7 and secondary screw hole 6 are corresponding to the main locking screw hole 4. During application, the secondary locking screw hole 7 and secondary screw hole The holes 6 are respectively distributed on both sides o...

Embodiment 2

[0037] Depend on Figure 9 , Figure 10 , Figure 11It can be seen that in this embodiment, the main locking and compression bone plate 1 is provided with 8 main locking screw holes 4, one of which is a pressure hole 10, and the auxiliary locking bone plate 5 is provided with 3 auxiliary screw holes 6 and 1 auxiliary screw hole. The locking screw hole 7 corresponds to the main locking screw hole 4 in position and size, and is used for internal fixation of various types of proximal joint fractures.

[0038] Its operation method is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com