Iron Powder for Powder Magnetic Core

A powder magnetic core and iron powder technology, applied in the direction of magnetic core/yoke, magnetic materials, magnetic objects, etc., can solve the problem of limited freedom and achieve low hysteresis loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

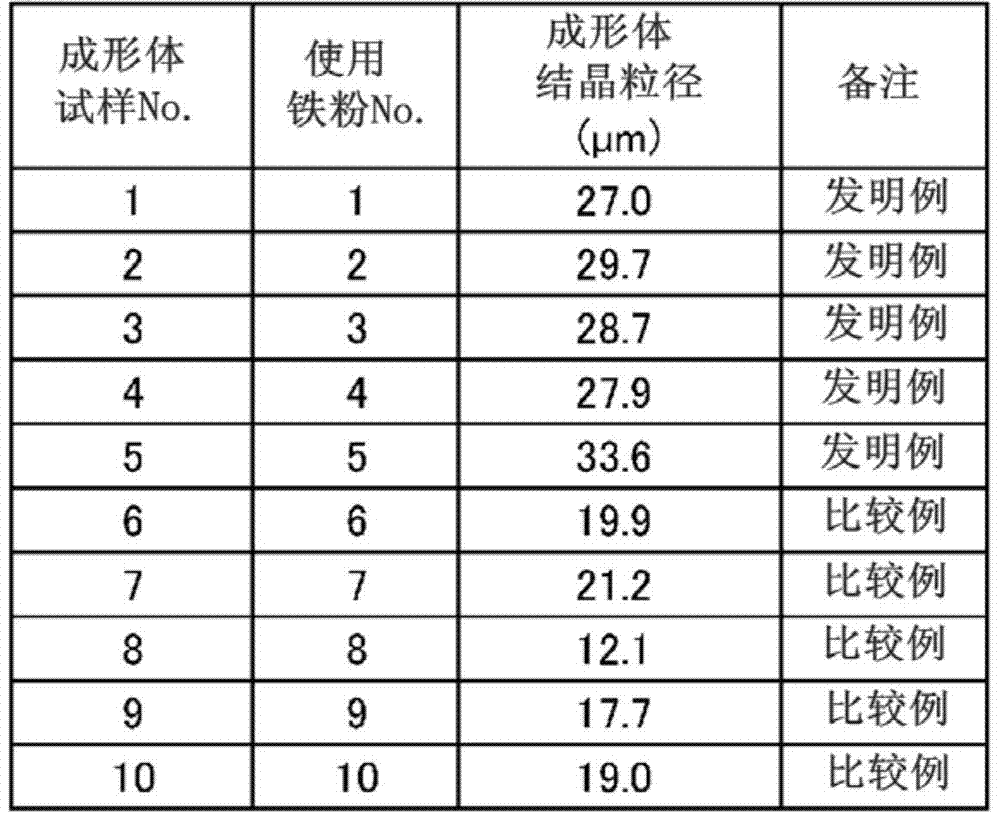

[0075] The iron powder used in this embodiment is set to be 10 kinds of atomized pure iron powders with different apparent density, D50, crystal grain size, amount of inclusions and micro-Vickers hardness.

[0076] In addition, the apparent density is 3.8g / cm 3 The above iron powder is gas atomized iron powder, the apparent density is lower than 3.8g / cm 3 The iron powder is water atomized iron powder. Regarding the composition, any powder is C<0.005 mass%, O<0.10 mass%, N<0.002 mass%, Si<0.025 mass%, P<0.02 mass%, S <0.002% by mass.

[0077] [Table 1]

[0078] Table 1

[0079]

[0080] These powders were subjected to insulating coating with a silicone resin. The silicone resin was dissolved in toluene to prepare a resin diluted solution so that the resin content was 0.9% by mass, and then, the powder was mixed with the resin diluted solution so that the addition rate of the resin to the powder was 0.15% by mass. Allow to air dry. After drying, a resin sintering treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com