Iterative decomposition method for automobile interior noise development objective

A technology for interior noise and automobiles, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as large design changes, design changes, and constraints that are not considered in the later stage, so as to avoid uncertainty , solve the effect of difficult decomposition and high decomposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

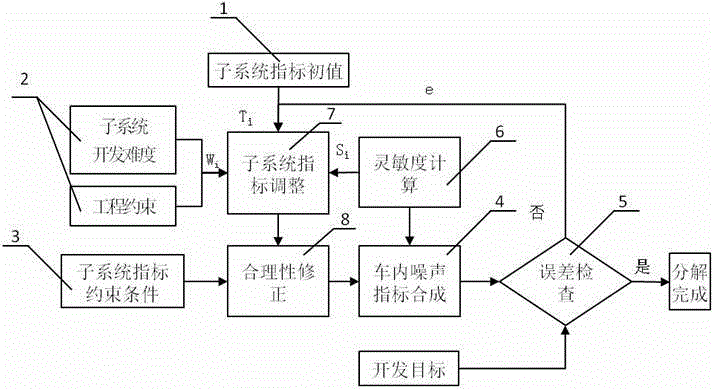

[0027] The present invention is further described below in conjunction with accompanying drawing:

[0028] see figure 1 , the iterative decomposition method of automobile interior noise development target of the present invention, its steps are as follows:

[0029] (1) Set the iterative initial value T of the vibration and noise performance design index of each subsystem of the automobile i , the initial value of the iteration is determined according to the actual development situation. For a system that cannot be changed during the development process, the initial value of the iteration is set to the actual test value of the system; for the system to be developed, the initial value of the iteration is set to the empirical value of the system performance index or mean.

[0030] Specifically, the iterative initial value T i Include Incentive F i and path H i Two aspects, F i 、H i Both are subsystem design indicators, where F i Dynamic force at the excitation point for s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com